AN UPDATE ON THE

MEASUREMENT OF PM EMISSIONS

AT LEV III LEVELS

This report has been reviewed by the staff of the California Air Resources Board and

approved for publication. Approval does not signify that the contents necessarily reflect the

views and policies of the Air Resources Board, nor does the mention of trade names or

commercial products constitute endorsement or recommendation for use.

Date of Release: October, 2015

TABLE OF CONTENTS

Page

EXECUTIVE SUMMARY 1

I. BACKGROUND 4

II. PM EMISSION TESTING 7

a. General Test Procedures 7

b. New Protocols for Light-Duty Vehicle Emissions Testing in 11

40 CFR Part 1066 PM Test Procedures

III. FINDINGS ON THE GRAVIMETRIC METHOD 14

a. PM Emissions below 1 mg/mi levels from Pre-LEV III LDVs 14

b. Source of Measurement Variability 16

c. Evaluation of PM Sampler Equivalency and

Measurement Precision 26

d. Equivalency of CFR PM Sampling Options 31

IV. ALTERNATIVE METRICS FOR PARTICULATE MASS

DETERMINATION 36

a. PMP Method: Solid Particle Number Measurement 39

b. Particulate Mass Estimation Using Particle Size

Distribution and Particulate Effective Density 46

c. Black Carbon 49

Combination Methods: Apportionment of PM mass

with BC measurement

V. INDUSTRY CONCERNS AND ISSUES ON MEASURING PM

MASS EMISSIONS AT VERY LOW LEVELS 54

VI. CONCLUSIONS 57

VII. REFERENCES 61

VIII. APPENDIX 67

IX. ACRONYMS AND ABBREVIATIONS 79

ii

EXECUTIVE SUMMARY

The California Air Resources Board (ARB) adopted more stringent particulate matter

(PM) emission standards as part of the Advanced Clean Cars program and its Low

Emission Vehicle (LEV) III regulations in 2012. During the proceedings, the Board

directed staff to report back to address industry’s concerns both on the feasibility of PM

mass measurement at very low emissions levels and on the technicological feasibility

for vehicles, especially those with technologies expected to be used to meet the

national greenhouse gas standards, to meet the future standards. Since then, ARB

staff, in collaboration with the United States Environmental Protection Agency (U.S.

EPA), industry, and other stakeholders, has been working on the first of those two tasks

and has completed extensive studies to verify the feasibility of measuring PM emissions

at the levels required to comply with the LEV III 1 milligram per mile (mg/mi) standard.

Several of these studies were focused on investigating concerns regarding the limitation

of the gravimetric measurement method that has been historically used in vehicle

testing to determine PM mass. In addition, ARB staff continues to explore and evaluate

other metrics for measuring PM emissions. For the second task of confirming the

feasibility of the standard for vehicles (and the appropriate implementation timing of the

standard), testing will be carried out over the next year with a report back to the Board

scheduled for late 2016.

Gravimetric Method is Suitable for Measuring PM Emissions below 1 mg/mi

Through this research, ARB staff has concluded that the gravimetric method specified

for vehicle emission testing in 40 Code of Federal Regulations (CFR) Part 1065/1066 is

indeed suitable for measuring PM mass emissions at the sub 1 mg/mi level. This

conclusion is based on evaluations of the potential sources of measurement variability,

determination of the PM measurement precision, and a comparison of collocated

measurements of selected sampling options described in 40 CFR Part 1066.

Gravimetric Measurement Variability

The total variability in the gravimetric analysis can be estimated by combining the

sources of variability related to filter sampling, handling, and weighing. These sources

of variability are quantified by repeatedly measuring the “mass loading” on blank filters

— filters exposed to various points of the sampling/measurement environment but not to

the vehicle exhaust. The variability of reference blanks, which are only exposed to the

weighing room environment, indicates microbalance stability and cleanliness in the

clean room. Trip and field blanks are indicators of additional contamination introduced

by sampling media preparation and handling outside of the clean room; whereas tunnel

blanks, which are exposed to the entire sampling process including dilution air but still

excluding vehicle exhaust, determine overall variability in sampling processes and the

typical contribution from background dilution air.

In ARB studies, the average mass loadings of reference, trip, and field blanks are very

close to zero, indicating that minimal contamination is introduced by ARB’s filter

1

handling procedures. Typical levels of tunnel blanks in ARB’s Haagen-Smit Laboratory

(HSL) test cells average ~2.1 micrograms (µg, 1 µg = 0.001 mg). Relative to field

blanks average, mass loading on tunnel blanks are slightly higher, representing the

additional contribution from background dilution air and the sampling tunnel.

The variability of the gravimetric analysis is calculated from the standard deviations of

reference blank measurements. The standard deviations of ARB’s reference blanks are

~0.5 µg, indicating that the variability from the microbalance is very low. Trip and field

blanks undergo more handling by testing personnel and exposure to the vehicle test cell

and therefore, have an expected higher variability with one standard deviation of 2 µg at

ARB. Tunnel blank results encompass additional variability due to dilution air

background and potential sampling tunnel contamination, yet the standard deviation of

tunnel blanks increases only slightly (by an additional 0.5 µg) to 2.5 µg. The average

and variability of tunnel blank results show that the subtraction of up to 5 µg allowed by

the official test procedures to account for background contamination is sufficient.

For frame of reference, if we take the worst case scenario of adding an additional one

standard deviation of mass loading (2.5 ug) to each of the three phases of the FTP

emission test and all in the direction of adding mass to the filter, the impact would be an

uncertainty of less than 0.1 mg/mi, or 10% of the 1 mg/mi PM emission

standard. Furthermore, if a single filter sampling method is used instead of the

traditional 3-filter method, the contribution is reduced to approximately 5% of the 1

mg/mi standard.

Precision and Reproducibility of the Gravimetric Measurement

The precision of the gravimetric measurement was established by measuring PM mass

with five collocated gravimetric samplers, and then comparing the relative deviations of

the multiple measurements across a fleet of vehicles spanning a range of emissions at

or below a 1 mg/mile level. Measurement precision is a quantification of the possible

errors due solely to measurement, excluding any differences caused by variability of the

vehicle emission levels. ARB’s study determined that the precision is 11% (or 0.1

mg/mile) at sub 1 mg/mi levels.

To establish vehicle test reproducibility, ARB carried out an in-house correlation study

with one vehicle and an average of nine repeat PM emission measurements per test

cell in each of three different light-duty vehicle (LDV) test cells. The study showed that

the three test cells utilized can reproducibly measure PM emissions at sub 1 mg/mile

levels. The vehicle test-to-test variability was determined to be greater than the inter-

laboratory (test cell-to-test cell) variability, suggesting that the instability of the emission

source (vehicle) can be a critical factor in determining the total vehicle testing

reproducibility.

2

Equivalency of CFR Sampling Options

ARB’s study showed that the single filter, flow-weighted sampling method allowed in 40

CFR Part 1066 for FTP testing yields an emission rate equivalent to that of the

conventional 3-filter sampling method, provided they are both corrected with the actual

PM background (e.g., tunnel blank). The single filter method also has the advantage of

reducing the material and labor costs needed. The test results show that these two

sampling options are equivalent.

Evaluation of Alternative Methods

ARB staff has evaluated several approaches for measuring PM mass that incorporate

alternative metrics for PM, including those based on solid particle number (SPN),

integrated particle size distribution with effective density, and black carbon (BC)

measurement. PM mass results determined by all three methods correlate well with

gravimetric PM mass. However, the slopes of the correlations vary by test cycle and

engine technology as does the variability in PM mass. The observed relationship

between PM mass and real-time methods (particle number and BC) strongly suggests

that regulating PM emissions through a mass standard will simultaneously reduce the

emissions of solid particles and black carbon.

The SPN method is used as one of the metrics for LDV PM standards and emission

measurement by the European Union. It is of special interest because it is the only

method besides the gravimetric method that has been subjected to rigorous

international round robin studies. Although previous studies have reported more

repeatable emission measurements with the SPN method and there are potential cost

savings with the method, one major drawback is that it only measures a portion of the

constituents that make up the total PM emissions. Specifically, it does not measure the

semi-volatile components nor particles smaller than 23 nm in diameter. Various studies

have shown that the portion of PM attributed to semi-volatiles or to particles smaller

than 23 nm can (and likely will continue to) vary substantially based on the engine fuel,

engine technology, and exhaust aftertreatment applied. Given the uncertainty as to

both the chemical nature of PM that future vehicles will emit and the possible effects in

adverse public health from PM in these excluded portions, ARB will continue to utilize

the gravimetric mass measurement method as the recognized method for official

emission tests. However, staff will continue to monitor developments from the

European Particle Measurement Programme (PMP) working group which is seeking

improvements in the SPN instrument calibration and extension of the particle size

measurement range to include smaller particles, possibly down to 10 nm in diameter.

ARB will also continue to follow the improvements in other methods and instruments for

measuring particle number and BC as well as any other promising emerging

approaches.

3

I. BACKGROUND

ARB LEV III PM Emission Standards

The California Air Resources Board (ARB) adopted the Low Emission Vehicle (LEV) III

PM emission standards as part of its Advanced Clean Cars (ACC) program in 2012.

Full implementation of the 1 mg/mi PM emission standard is achieved by model year

(MY) 2028. The standard is codified in title 13 section 1961.2, California Code of

Regulations, “Exhaust Emission Standards and Test Procedures - 2015 and

Subsequent Model Passenger Cars, Light-Duty Trucks, and Medium-Duty Vehicles”.

The regulation lowers the Federal Test Procedure (FTP) PM emission standard for

passenger cars, light-duty trucks, and medium-duty passenger vehicles in two phases.

The first phase lowers the standard to 3 milligrams per mile (mg/mi) over a phase-in

period starting with MY 2017 vehicles and reaching full implementation by MY 2021.

The second phase further lowers the FTP PM emission standard to 1 mg/mi beginning

with MY 2025, and reaches full implementation in MY 2028.

0

2

4

6

8

10

12

Current 2017 2025

PM Emissions (mg/mi)

Figure I-1. LEV III FTP PM standards for passenger cars, light-duty trucks, and

medium-duty passenger vehicles.

The U.S. Environmental Protection Agency (U.S.EPA) has also lowered the national PM

emission standards as part of the Federal Tier 3 regulations. Identical to the LEV III

program, the Federal Tier 3 program will limit FTP PM emissions to 3 mg/mi over a

phase-in period beginning in MY 2017 and reaching full implementation by MY 2021.

However, the EPA standards do not decrease to 1 mg/mi in later years like the LEV III

standards. In October 2014, ARB adopted additional minor changes to the LEV III

standards to more closely align with Federal Tier 3 standards without sacrificing any

emission benefits or the more stringent 1 mg/mi standard.

4

While the vast majority of gasoline vehicles today easily meet the existing 10 mg/mi PM

standard, the more stringent LEV III PM standards will prevent emission increases as

vehicle manufacturers transition to low greenhouse gas (GHG) emitting technologies,

some of which can increase PM emissions. The light duty vehicle fleet is currently

dominated by port-fuel injection (PFI) gasoline vehicles, the majority of which emit PM

at or below 1 mg/mi. In recent years, an increasing segment of the market share is

comprised of gasoline direct injection (GDI) vehicles, a technology that reduces fuel

consumption and therefore, GHG emissions, but sometimes increases PM emissions.

Engine technology is rapidly evolving as manufacturers introduce new variations of GDI

systems and components such as improved injectors, higher pressures, and different

mounting locations to reduce any undesired increase in PM emissions. Some other

GHG-reducing technologies such as non-stoichiometric gasoline operation have also

been mentioned as concerns where PM emissions may increase. In some cases,

vehicle manufacturers and suppliers are even investigating after-treatment devices such

as gasoline particulate filters (GPFs), similar in concept to the diesel particulate filters

(DPFs) already in use on light- and heavy-duty diesel vehicles.

Vehicle manufacturers have expressed concerns over the lower PM standards,

particularly the future 1 mg/mi standard. The uncertainty of the traditional filter-based

gravimetric method for measuring PM emissions at the 1 mg/mi level has been

perceived to be relatively high, thereby making reliable measurement extremely

challenging. In 2012, the Board directed staff to review and report back on the

feasibility of reliable measurement at these low levels and to re-assess the technical

feasibility (and appropriate implementation timing) of future vehicle technologies to meet

these tighter PM standards.

The LEV III regulations also include a more stringent PM emission standard for the

Supplemental Federal Test Procedure (SFTP), also known as the US06 cycle, which

represents much more aggressive driving speeds and accelerations than the FTP test

cycle. The magnitude of the US06 PM emission standard is significantly higher than

that of the FTP standard and, therefore, PM measurement uncertainty has a much less

significant impact on the test results. Accordingly, ARB staff focused its evaluation on

the measurement feasibility at levels required to meet the future FTP standards.

ARB adopted the updated federal test procedures (40 CFR part 1066) as part of the

LEV III update in October 2014. These new procedures include allowances for

background correction, as well as provisions for new PM sampling options. Current PM

sampling and measurement protocols along with the updated sampling options are

discussed in further detail in Section II. Staff’s findings on PM measurement feasibility

and on the alternative PM measurement metrics are presented in Sections III and IV,

respectively. Section V addresses stakeholders’ concerns regarding the limitations of

the gravimetric test method. Finally, Section VI summarizes findings and

recommendations regarding the suitability of the gravimetric test method for the LEV III

1 mg/mile PM emission standard, benefits and limitations of new sampling approaches

in LEV III and CFR test procedures, and an assessment of alternative PM measurement

metrics.

5

Regarding the Board’s request for staff to re-assess the technical feasibility of future

vehicles meeting the 1 mg/mi PM standard and the appropriate implementation timing

for that standard, staff has begun the analysis and will present its findings as part of the

comprehensive midterm review of the national GHG standards and ARB ZEV regulation

at a later date.

6

II. PM EMISSION TESTING

a. General Test Procedures

Light-duty vehicle (LDV) testing at ARB is conducted on a chassis dynamometer in a

test cell equipped with a Constant Volume Sampling (CVS) system and the associated

equipment for gaseous and PM mass emissions collection. Measurement of PM mass

during testing is carried out using prescribed procedures defined in 40 CFR Part 1065

and 1066, which cover everything from vehicle/fuel preparation to vehicle test cycles,

emissions sample collection, and the gravimetric determination of PM mass. Figure II-1

shows a picture of one of ARB’s LDV emission test cells and Table II-1 summarizes the

specifications of the three ARB LDV test cells used to carry out this evaluation. The

typical CVS flowrate of the FTP test cycle at ARB is 350 standard cubic feet per minute

(scfm).

ARB Cell 7

Figure II-1. A picture of an ARB test cell 7

LDV PM emissions are determined with gravimetric measurement by taking a sample of

diluted vehicle exhaust from the CVS and collecting PM on a 47mm

polytetrafluoroethylene (PTFE) filter. The sample is collected using a temperature-

controlled (47 ± 5°C) PM filter sampling system at a nominal flow rate of 60 standard

liters per minute (L/min, or 2.12 scfm). The typical filter face velocity for sample

collection is near 100 cm/s. The filter sample is then subjected to the gravimetric

analysis in an environmentally controlled clean room, maintained at a temperature of 22

± 1°C and a dew point of 9.5 ± 1°C. The clean room cleanliness meets the International

Organization for Standardization (ISO) standards for clean room environments (ISO

14644-1). Filters are equilibrated for a minimum of 30 minutes in the clean room prior to

7

carrying out the weighing on a microbalance (XP2U, Mettler Toledo, Columbus, OH).

Currently, ARB’s gravimetric analysis of filters is conducted using an automated

weighing system controlled by an MTL robotic weighing system, shown in Figure II-2,

with triplicate weighing and zero drift correction. The PM mass loading is the difference

between the pre-test and post-test buoyancy corrected filter masses. The weighing

procedure is detailed in SOP MV-AEROSOL-145 v5.2 (ECARS, 2011b) and the filter

handling and preparation procedure is described in SOPs MV-AEROSOL-156 and 158

(ECARS, 2014a and 2014b).

ARB HSL Test Cell

Cell A Cell B Cell C

Dynamometer

48" Burke Porter

2WD Electric

Dyno

48" Clayton 2WD

Electric Dyno

48" Horiba 2WD

Electric Dyno

Constant

Volume

Sampler (CVS)

AVL CVS 150-

900 SCFM

Horiba CVS 150-

1,000 SCFM

Horiba CVS

150-814 SCFM

Gas Analyzers

Horiba MEXA-

7200 LE

Pierburg AMA

4000

Horiba MEXA-

7200 LE

PM Sampler

1. AVL SPC

Sampler

2. Horiba Quad

Sampler

AVL SPC sampler

Horiba HF-PM

Sampler

Exhaust

Transfer Tube

3-4" Stainless

Steel Tube

3-4" Stainless

Steel Tube

3-4" Stainless

Steel Tube

Table II-1. Summary of testing equipment in ARB light-duty vehicle test cells

8

Figure II-2. An operator loads filters on ARB’s automated filter weighing system.

Driving Cycles

LDV PM emission standards are tied to specific driving cycles on a chassis

dynamometer. The driving cycle is intended to represent a specific duty or activity of a

vehicle during its operation. The two most relevant drive cycles for LDV PM emission

standards are the standard Federal Test Procedure (FTP) and the high speed, high

acceleration portion of the Supplemental Federal Test Procedure (SFTP or US06).

Federal Test Procedure (FTP)

The FTP consists of two Urban Dynamometer Driving Schedules (UDDS) run in series

(Figure II-3). Each UDDS is divided into two phases, with a start phase running for 505

seconds and a stabilized phase running for an additional 864 seconds. The first UDDS

is considered a cold start test because the engine is started in a “cold” condition after an

overnight engine off ‘soak’ period. The second UDDS is considered a hot start test

because it begins with a “hot” engine from a car that has been sitting with the engine off

for 10 minutes after the first UDDS ends. The stabilized phase in both UDDS cycles is

assumed to have the same emissions; therefore, it is typically not run after the hot start.

This “three-phase” driving schedule is commonly referred to as an FTP-75. The FTP-75

has a total distance travelled of 11.04 miles, an average speed of 21.2 miles per hour

(mph), and a total duration of 1874 seconds. The emission result is a weighted average

where the cold start and stabilized phase (the first UDDS cycle) is weighted at 43

percent and the hot start and stabilized phase (equivalent to the second UDDS) is

weighted at 57 percent.

9

Figure II-3. The FTP cycle speed trace

Source: http://www.epa.gov/otaq/standards/light-duty/ftp.htm

Supplemental Federal Test Procedure (SFTP or US06)

The US06 was developed to reflect aggressive, high speed, and high acceleration

driving behavior. The US06 driving cycle is shown in Figure II-4. It is a hot start test

typically run with two replicate US06 cycles. The first US06 cycle is a prep cycle, run

without emission measurement, to ensure the car is warmed up; the second US06

immediately follows the first, without an engine off or restart, and emissions are

measured on the second cycle. The US06 cycle represents an 8.01 mile route with an

average speed of 48.4 mph, maximum speed 80.3 mph, maximum acceleration rate of

8.46 mph/sec, and duration of 596 seconds. The higher acceleration rates and speeds

of the US06 cycle lead to higher engine loads, which typically generate higher PM

emission rates.

10

Figure II-4. The US06 cycle trace of the SFTP

Source:http://www.epa.gov/nvfel/methods/us06dds.gif

Test Fuel

The Phase 3 gasoline certification specifications were adopted as part of the LEV III

regulations and specify a number of components in the test fuel. It has been shown that

the sulfur, olefinic, and total aromatic hydrocarbon content in the fuel could affect PM

emissions (Khalek et al., 2010 and Aikawa et al., 2010). Phase 3 certification fuel

replaced MTBE with ethanol (E10) as the oxygenate, and set specifications for other

parameters to better reflect the current composition of transportation gasoline sold

commercially in California. These specifications are detailed in Part II, Section

A.100.3.1.2 of the “California

2015 and Subsequent Model Criteria Pollutant Exhaust

Emission Standards

and Test Procedures and 2017 and Subsequent Model Greenhouse

Gas

Exhaust Emission Standards and Test Procedures for Passenger Cars, Light-

Duty

Trucks, and Medium-Duty Vehicles.”

b. New Protocols for Light-Duty Vehicle Emissions Testing in 40 CFR Part 1066

PM Test Procedures

40 CFR Part 1066 provides two new features for PM emission testing that include 1)

five different PM sampling options with their calculations, and 2) an allowance for

background correction. These elements are described in the following paragraphs.

PM Sampling Options

The U.S. EPA has led an effort to improve and standardize the test methods prescribed

in the CFR for vehicle testing. This effort resulted in the creation of Part 1066 which

11

ARB has adopted along with 40 CFR Part 1065 for its vehicle compliance testing

programs. One of the updates to 40 CFR part 1066.815 (Exhaust emission test

procedure for FTP testing) includes four additional PM sampling options, listed in Table

II-2 as options 2 through 5. These sampling options were intended primarily to increase

the amount of PM sampled and minimize uncertainties by reducing the number of filters

used. However, some options require extending emission test time to encompass two

full UDDS cycles, while others may result in laboratories needing two samplers. Option

1 is the original FTP test procedure and is used as a benchmark, whereas sampling

option 4 has been evaluated extensively as part of ARB’s efforts to determine the

feasibility of PM measurement at levels below 1 mg/mi. The results of ARB’s

comparison are presented in Section III.

Option

Description

No. of

Filters

Filter Face Velocity

Weighting Target

1

1 filter/phase of three-phase FTP

3

1.0/1.0/1.0

2

1 filter/UDDS of four-phase FTP

2

1.0/1.0/1.0/1.0

3

1 filter/phase 1&2 +

1 filter/phase 2&3

2

1.0/1.0/1.0

4

1 filter/three-phase FTP

1

0.43/1.0/0.57

5

1 filter/four-phase FTP

1

0.75/0.75/1.0/1.0

Table II-2. Summary of five PM sampling options described in 40 CFR Part 1066. The

maximum nominal filter face velocity is 100 cm/sec for all sampling options.

PM Background Correction

The subtraction of background PM mass allows corrections for a measurable bias. 40

CFR Part 1066 allows background correction of up to 5 µg, or 5% of the net PM mass.

The major sources of bias include dilution air contamination, as well as sampling train

and filter media adsorption/desorption effects. Not only do the contamination sources

contribute to undesirable background interference, but they could also increase

measurement variability. However, PM background interference and vehicular PM

emissions cannot be quantified simultaneously. The interference caused by deposit of

exhaust emission constituents onto the wall of the sampling train, and re-evaporation

and re-entrainment of those deposits back to the sample stream is dynamic, and

depends on the chemical nature of these constituents, as well as the temperature

gradient between the exhaust stream, dilution tunnel, and dilution air. Furthermore,

these interferences can undergo chemical reactions with the exhaust, the nature of

which also varies in transient test cycles.

12

In addition to the interferences and uncertainties in the CVS tunnel, filter sampling

media can also contribute to measurement uncertainties. Different filter materials have

unique characteristics for adsorption and desorption of gaseous organics. The use of

PTFE filters has resulted in the least degree of interference from gaseous organic

compounds (Chase et al., 2004 and Khalek 2005), whereas, earlier studies show TX40

and quartz fiber filters have a propensity to adsorb organic hydrocarbons and tend to

show much higher background levels and measurement uncertainty. Good filter

handling practices can also minimize the PM mass measurement variability.

13

III. PM MASS MEASUREMENT FINDINGS

a. PM Emissions below 1 mg/mi levels from Pre-LEV III LDVs

Prior to the 2012 LEV III rulemaking, ARB began monitoring PM emissions from LDVs

and assessing the capabilities of the gravimetric measurement method. The results

were discussed in the LEV III PM Technical Support Document, Appendix P. In this

effort, 19 LDVs, comprised of nine GDI and 10 PFI vehicles were tested using the FTP

cycle and California Phase 3 commercial summer fuel containing 6% ethanol by

volume. For the nine GDI test vehicles (Figure III-1), PM mass emissions were the

highest in phase 1 (cold start), with an average of 14 mg/mi; after engine warm up, PM

emissions were significantly reduced with an average of 1.1 mg/mi for phase 2

(stabilized phase) and 1.5 mg/mi for phase 3 (hot start). The FTP weighted average PM

mass emissions for the nine GDIs was 3.87 mg/mi. Detailed GDI vehicle information

and corresponding PM emission rates are listed in Appendix Table A-1.

Figure III-1. PM mass emission rates on FTP cycle for 9 GDI vehicles using

California E6 summer fuel (LEV III PM Technical Support Document, 2012)

The FTP weighted average PM emissions for the ten PFI vehicles (listed in Appendix

Table A-2) was 0.5 mg/mi, with a range of 0.16 mg/mi to 0.99 mg/mi. The results are

shown in Figure III-2, along with the US EPA’s test results from a set of 13 vehicles,

Vehicles A to M (detailed in Appendix Table A-2). These PM emissions were measured

in three test cells at the HSL and one test cell at US EPA’s National Vehicle and Fuel

Emissions Laboratory (NVFEL). The coefficient of variance (CoV, the ratio of the

14

standard deviation divided to the mean of results from repeating tests, also known as

relative standard deviation) from vehicles where there was three or four repeat tests

varied from 5 to 56% and was found to be independent of the PM emission rates.

Vehicles

Veh 1

Veh 2

Veh 3

Veh 4

Veh 5

Veh 6

Veh 7

Veh 8

Veh 9

Veh 10

Veh A

Veh B

Veh C

Veh D

Veh E

Veh F

Veh G

Veh H

Veh I

Veh J

Veh K

Veh L

Veh M

PM Emissions, mg/mile

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

COV, %

0

10

20

30

40

50

60

Pre-2004

MY 2005-2009

ARB Study

U.S. EPA Study

PC

LDT

MY 2005-2009

MY 2006-2009

PC

PC

w/o background corrections

w/ background corrections

• X is the coefficient of variance of the testing results.

• No error bar indicates only one test was performed.

• Error bars show one standard deviation

Figure III-2. PM emission rates of LDVs tested at ARB’s HSL cell A and US EPA’s

NVFEL cell (Hu et al., 2014)

Repeat gravimetric measurements of FTP phase 2 and phase 3 PM emission rates for

GDI vehicles and FTP weighted PM emission rates for PFI vehicles demonstrated that

the gravimetric PM mass measurement method was capable of measuring PM mass

emission rates at ~1 mg/mi or lower.

In addition to the work at the U.S. EPA and ARB, other laboratories have also measured

low level PM emissions. Chase et al. (2000) reported that PM emissions from 11 LDVs

had a mean FTP-weighted emission rate of 0.60 ± 0.17 mg/mi for six low mileage

vehicles and 0.67 ± 0.19 mg/mi for five high mileage vehicles. Maricq et al. (2011) also

reported measurements of LDV PM emissions at LEV III levels.

A statistical analysis was conducted to verify the ability of a test cell to distinguish

vehicles with various PM emission levels. The PM emissions from vehicles with more

than three repeat tests and ranging from 0.2 to 0.99 mg/mi (Vehicles 1, 7-10) were

pooled to calculate test-to-test variability (

), vehicle-to-vehicle variability (

), and total

15

variability (

) by the equations listed in “Statistical Analyses _Repeatability and

Reproducibility” in the Appendix. Using this statistical analysis, vehicle-to-vehicle and

test-to-test variability were compared to verify vehicles emitting at different PM levels

could be distinguished in the test cell. The calculated results are shown in Table III-1.

The vehicle-to-vehicle variability was found to be at least two times the test-to-test

variability. When one outlying emission value from Vehicle 8 is excluded, the vehicle-to-

vehicle variability becomes even more dominant while the CoV for test-to-test

repeatability decreases from 30% to 16%. The vehicle-to-vehicle variability accounts for

more than 90% (excluding the outlier) or 70% (all data) of the total emission variability.

These results suggest that the test cell itself can distinguish different levels of vehicular

PM emission below 1 mg/mi.

Variability Coefficient of Variance

Emissions Test-to-Test Vehicle-to- Total

mg/mile

2

Vehicle

2

Variability

2

CoV

r

CoV

L

CoV

R

PM 0.65±0.34 0.04 0.09 0.13 0.30 0.46 0.55

PM

a

0.60±0.26 0.01 0.08 0.09 0.16 0.47 0.49

a. One suspicious “outlier” value of 1.53 mg/mi was excluded from Veh 8 to evaluate the influence of this

high value on the variability.

Table III-1. Repeatability and reproducibility of five vehicles (Vehicle 1, 7-10) tested at

ARB HSL test cell A (Hu et al, 2014)

Although the ability to measure PM mass repeatedly below 1 mg/mi has been

demonstrated, there are still some concerns regarding the measurement uncertainty

related to vehicle emission testing. To better understand the sources of measurement

uncertainty, ARB has conducted numerous tests to identify these sources, quantify

variability, and further confirm the feasibility of the gravimetric method for vehicle

emission certification testing.

b. Sources of Measurement Variability

To fully characterize the uncertainty of vehicle PM emission measurements, it is

essential to understand how the test is conducted and where the measurement

variability is influenced. Vehicle dynamometer testing contains three major potential

sources of variability, shown in Figure III-3:

16

(a) Emission source: the vehicle itself and a driver

Repeatability of PM emissions can be influenced by the variation of the engine

combustion process, and slight test-to-test variations in engine speed and load

operation that occur as the driver follows within a transient driving trace.

(b) Sampling train: heated transfer tube, dilution tunnel, dilution air, PM sampling

system, and sample collection media

The dilution air background and adsorption/desorption characteristics of semi-

volatile organic compounds in the sampling train can contribute the total

measurement variability. In addition, the PTFE filter’s property of

adsorption/desorption of organic hydrocarbons during sample collection can also

contribute to variability.

(c) Gravimetric analysis to determine the PM mass

The stability of the microbalance and environmental conditions in the clean room

can also contribute to measurement variability.

Transfer tube

Dilution tunnel

Filter sampler

Dilution Air

Figure III-3. Schematic illustration of the gravimetric method for determining PM mass

emissions in vehicle exhaust. (Modified from Mayer, 2006)

17

Blank sample measurements as indicators of sources of variability

ARB routinely measures background/blank samples to identify possible areas of

contamination as the filter is transported through each step of vehicle testing. The

results are used to quantify the variability from gravimetric analysis (reference and

replicate analysis), the filter handling process (trip and field blanks), and the sampling

train (tunnel blanks) to estimate potential background contributions to total vehicle

emission measurement variability. The various blank samples are diagrammed in

Figure III-4 to illustrate their relative contributions (not to scale) to variability.

Reference

Replicate

Trip blank

Field blank

Tunnel blank

Gravimetric

Analysis

Figure III-4. Schematic of sources of total variability determined from filter blanks. The

relative contribution is not to scale. (modified from Watson et al. 2013 CRC Workshop)

Variability from Gravimetric Analysis: Reference Filter and Replicate Analysis

The vehicle PM emissions are collected onto a PTFE filter and the filter weight

determination can be influenced by environmental conditions. Therefore, it is important

to evaluate the measurement variability of reference, replicate filters, and NIST

traceable metal weights for quality assurance (QA).

The NIST Traceable Metal Weight

The filter weighing is conducted using an MTL robotic filter weighing system with

triplicate weighing and zero drift correction The NIST traceable metal weight is used to

validate the microbalance calibration. Figure III-5 shows the metal weight

measurements from April to September, 2014. The NIST metal weight ranged within

0.7 µg in six months, indicating excellent microbalance stability.

18

99.987

99.9871

99.9872

99.9873

99.9874

99.9875

99.9876

99.9877

99.9878

99.9879

3/22/2014 5/1/2014 6/10/2014 7/20/2014 8/29/2014 10/8/2014

Metal weight, µg

dates

Figure III-5. NIST traceable metal weight measurements for a period of six months.

Reference Filter Blanks

Three reference filters, stored in the weighing room environment, are weighed at the

beginning and the end of each sample (filter) weighing session. Typical weighing

sessions last several hours, depending on the number of samples. Reference filters are

used to check for particle contamination in the clean room environment and weighing

system stability during a weighing session. The reference filters’ mass difference (the

change of buoyancy corrected net mass of reference filters during each weighing

session) along with results from various types of blanks, are shown in Figure III-6. The

mean difference for the reference filters was -0.4 µg with one standard deviation of 0.5

µg, determined by a total of 138 reference filter samples collected during the period of

January to June, 2014.

Replicate samples

A replicate is a vehicle emission filter randomly selected for repeat weighing from each

batch of ten samples. Replicate results were used to assess measurement repeatability

for different filter PM mass loadings. The variability of repeat analysis is shown in

Figure III-6 for over 100 samples collected from January through June 2014 at the ARB

laboratory. The mean and standard deviation were 0.1 ± 0.5 µg. The results from

replicate analyses demonstrated that the performance of the weighing system is stable.

19

-4

-2

0

2

4

6

8

10

Reference Replicate Trip Field Tunnel

Phase 1

Tunnel

Phase 2

Tunnel

Phase 3

Tunnel

Composite

Weight Avarage, µg

Gravimetric

Analysis

Filter Handling

Tunnel Blanks

Figure III-6. Average and standard deviation of blank filters.

In summary, the QA system consisting of NIST traceable metal weights, replicate filters,

and reference filters verified the stability of the robotic filter weighing system and

cleanliness of the weighing room. The average and standard deviation results are

relatively insignificant, compared to other blank measurements (discussed later).

Jung et al. (2015) compiled reference filter results from 13 laboratories using either

manual or robotic weighing, as shown in Figure III-7. The robotic weighing system (labs

4, 6, and 9) exhibited the lowest average bias (mean of reference filters) and standard

deviation of reference filters, and the results were very similar to ARB’s. When

including the results from manual weighing, the 50

th

percentile of the average variability

for laboratories is 2 µg with the 5

th

and 95

th

percentile at 0.6 and 4.99 µg, respectively.

20

Error bars represents the one standard deviation of the average results for each short-term pair evaluated.

Figure III-7. Average reference filter weight differences for the pooled filters (outliers

removed) (Jung et al., 2015)

Variability from Filter Handling: Trip and Field Blanks

Trip Blanks

A trip blank is a filter randomly selected among a set of pre-weighed filters, transported

to the test cell where it is stored (but not used for sampling or exposed to the testing

facility environment) during vehicle testing, and then returned to the weighing room.

The designated trip blank is weighed in the same weighing session along with the PM

samples. A total of 146 trip blanks were collected from four ARB test cells during 2013

and 2014, and the results are shown in Figure III-6. The average of the trip blanks is

0.4 µg, with a standard deviation of 1.9 µg. As expected, the trip blank has more

variability than that of the reference filters. Trip blanks encompass additional sources of

variability such as the assembly and disassembly of the filter cassettes used to house

the sample filters.

Field Blanks

Compared to the trip blank, the field blank captures additional variability introduced by

loading the filter onto the sample holder for the duration of vehicle testing, but without

exposure to tunnel dilution air or vehicle exhaust. The average of the field blank results

21

is shown in Figure III-6. The average mass of 40 field blanks from two of ARB’s test

cells is 0.2 µg with a standard deviation of 2.2 µg. The lack of any increased mass

loading over trip blank results indicates that the additional assembly and disassembly of

the filter cassette onto the filter holder, and exposure to tunnel air (without flow) does

not increase the mass loading or the measurement uncertainty.

The average mass loadings for trip and field blanks were close to zero, indicating that

filter handing procedures do not result in significant filter contamination. However, an

elevated standard deviation was observed for trip and field blanks when compared to

that of the reference or replicate analysis.

Variability from the Dilution Sampling System: Tunnel Blanks

Vehicular tailpipe exhaust is drawn through a heated transfer tube to the CVS dilution

tunnel, where the exhaust is diluted with filtered ambient air. ARB uses the tunnel blank

to evaluate the contribution from sampling system to measurement variability with the

transfer tube sealed.

Tunnel Blanks

At ARB’s test cells, tunnel blanks are typically collected every week using the same PM

sampling system used for vehicle testing, except that the vehicle exhaust inlet (or the

transfer tube) to the CVS tunnel is sealed. The sampling duration and flow rate are the

same as those in vehicle emission testing; however, the temperature profile in emission

testing (e.g., due to variations in vehicle exhaust temperature and mass flow during an

actual test) is not replicated. Tunnel blank results from three different programs at ARB

are tabulated in the Table III-2.

Tunnel Blank

Average (µg)

Standard

Deviation (µg)

Citation/program

Cell A (Phase 1, 2, 3)

2.5, 2.5, 1.8

2.7, 3.4, 3.1

Hu et al., 2014

Cell A (Phase 1, 2, 3,

1-filter-flow-weighted)

2.0, 2.1, 2.2

1.9

2.0, 1.9, 2.0

1.8

Sardar et al.,

(submitted)

Cell B (composite filter)

1.6

3.1

LDV surveillance test

(UC cycle)

Table III-2. ARB’s tunnel blank results from various vehicle test programs

Tunnel background levels were measured for tunnel blank tests from ARB’s test cell A,

prior to ARB’s LEV III rulemakings in 2012 (Hu, et al., 2014). Additional tunnel blanks

were collected from various ARB projects beginning in 2012. The utilization of only one

brand of PTFE filter (Whatman) and the implementation of a robotic filter weighing

system could help reduce the standard deviation of tunnel blank results (Sardar et al.,

submitted). ARB’s test cell B, which primarily carries out the emission tests for in-use

22

surveillance testing programs, showed similar results as those collected in test cell A

despite being exposed to significantly higher concentrations of PM mass.

Additional tunnel blank results, shown in Figure III-6, are from a total of 22 tunnel blank

samples collected for test cell A from September, 2013 through February, 2014,

including a full-flow 3-phase composite filter tunnel blank. The average and standard

deviation for the three phases and composite are 1.3 ± 2.0 µg (phase 1), 1.9 ± 2.9 µg

(phase 2), 1.0 ± 2.5 µg (phase 3), and 1.8 ± 1.9 (full flow composite).

The average tunnel blank mass loadings from ARB’s test cells was ~2.1 µg. Some

researchers suggest that the tunnel blank mass loading is from volatile or semi-volatile

hydrocarbons from the contaminants or wall losses of PM in the CVS tunnel while

others suggest it is from the dilution air. Nevertheless, official test procedures specified

in 40 CFR Part 1066 allow for a background ‘correction’ (subtraction) of up to 5 µg

which is sufficient to account for the observed tunnel blank background.

The average standard deviation of the tunnel blank results was approximately 2.5 µg,

which was slightly larger than that of trip and field blanks at 2 µg. The unpredictable

nature of contamination, either from the dilution air or tunnel wall, can increase

measurement uncertainty. The maximum tunnel blank measurement variability -

calculated by assuming that 2.5 µg is the PM mass loading for each FTP phase- is

equivalent to a 0.1 mg/mi FTP weighted emissions rate (350 scfm CVS flow rate and

100 cm/s filter face velocity). This theoretical worst case variability is approximately

10% of the 1 mg/mi emission standard and becomes even less significant (~ 5%) when

calculated using a single filter flow-weighted sampling option. Other investigators have

assessed the impact of tunnel blank uncertainty based on a standard deviation of 5 µg

(Bushkuhl et al., 2013), which is two times what has been observed at ARB. An

elevation of the standard deviation from trip blanks to tunnel dilution air blanks was

observed, attributed from the gaseous adsorption onto tunnel blank filters.

The results of a tunnel blank survey reported by Jung et al. (2015) are shown in Figure

III-8. Each participating laboratory had different practices for its tunnel blank

determination. The results show a large variation among laboratories. The average,

50

th

percentile, and standard deviation of all measurements (N=615) are 4.13, 2.8, and

3.62 µg, respectively. The 50

th

percentile of the variability (single standard deviation) for

the pooled laboratories is 2.8µg. If this tunnel blank variability reflects the overall

vehicle PM mass measurement uncertainty, improvements are needed for some

laboratories to quantify very low PM mass emissions.

23

95

th

= 13. 0 μg

50

th

= 2.8 μg

5

th

= 1.1 μg

Figure III- 8. Tunnel blank results from various laboratories (Jung et al., 2015)

To better understand the chemical characteristics of tunnel blank PM, ARB analyzed

PM samples for organic/elemental carbon. In addition to PM mass, collocated samples

were collected onto quartz fiber filters over the California Unified Cycle (UC) as part of

ARB’s LDV in-use surveillance program Series-19 conducted in test cell B. Both tunnel

blank tests (24 tests) and trip blanks (25 PTFE and 14 quartz fiber filters) were

conducted during the period from April 2013 to July 2014.

Sampling with quartz fiber filters allows for carbon analysis, which can differentiate

organic from elemental carbonaceous compounds. The quartz filter is pre-cleaned to

remove any contaminants before measurements. After PM sampling, the filters are

analyzed for organic carbon (OC) and elemental carbon (EC) using a Thermal/Optical

carbon analyzer following the IMPROVE_A protocol. Detailed analytical procedures

can be found in SOP MV-AEROSOL-139 v 1.1 (ECARS, 2011a).

24

-2

0

2

4

6

8

10

12

14

16

18

20

PM mass EC+OC PM mass EC+OC

µg/filter

Tunnel Blank

Trip Blank

OC

Tunnel Blank

Trip Blank

OC

OC

EC

Figure III-9. Average tunnel and trip blank PM mass and carbon analysis results from

ARB Test Cell B

As shown in Figure III-9, the average trip blank (25 samples) PM mass loading on the

PTFE filter was -0.5 ± 1.4 µg. The quartz filters were pre-baked at 900

o

C to reduce

background OC and EC. The quartz trip blank filters showed OC levels at 10.8 ± 4.1 µg

and 17.2 ± 3.9 µg OC level for tunnel blanks. However, the EC for both trip and tunnel

blanks were below the reporting limit (<2 µg). Although the high OC level in tunnel blank

is found, the average tunnel blank mass of 1.6 µg suggests that the adsorption of OC

from the dilution air onto PTFE filters is negligible.

The actual tunnel blank OC level should be much less when taking into account the trip

blank results. It is well known that quartz materials tend to adsorb organic volatile and

semi-volatile compounds to a greater extent than PTFE materials. This phenomenon,

sometimes referred to as “artifact” has been extensively studied in ambient particulate

matter sampling studies (Kirchstetter et al., 2001, and Turpin et al., 2000) as well as in

studies that sampled a mixture of pentadecane/soot on a coated glass fiber (Högström

et al., 2012). Although OC adsorption on filters is not completely understood, a variety

of correction approaches have been investigated, such as secondary filters and

denuders (Maricq et al., 2011, Mader et al., 2001, and Subramanian et al., 2004).

In an effort to reduce background contamination, ARB’s routine practice is to use

charcoal filters followed by high-efficiency particulate air (HEPA) filters to remove PM

and reduce organic carbon. The efficiency of contaminant reduction has been reflected

in reduced tunnel blank levels.

25

c. Evaluation of PM Sampler Equivalency and Gravimetric Measurement Precision

Two PM samplers, a Horiba Quad PM sampler and a collocated AVL 472 SPC PM

sampler, were used in a study to evaluate measurement precision and sampling unit

equivalency. The Horiba Quad PM sampler was connected to the CVS dilution tunnel

with a single inlet, which was subsequently divided into four air streams to feed into four

identical PM filter units.

A total of twelve vehicles, including two GDI and 10 PFI vehicles, were tested over 86

tests (FTP and US06). Vehicle information is presented in Appendix Table A-3.

Weighted PM emission rates over the FTP cycle were below 3 mg/mi and,

predominantly, below 1 mg/mi.

The vehicles were tested using California Phase III certification gasoline fuel, with the

exception of vehicles 6 and 7, which were tested using EPA Tier 2 Indolene fuel.

Sample probes for PM measurement were located near the tunnel center line and 10

tunnel diameters downstream of the mixing point. The schematic of the sampling setup

along with particle size and counting instruments is shown in Figure III-10.

DILUTION TUNNEL

TSI EEPS

3090

AVL SPC

PM Sampler

Horiba Quad

PM Sampler

CPC

Vehicle

Exhaust

Dilution Air

Filter box

Figure III-10. A schematic of the ARB LDV emission laboratory setup including CVS dilution

tunnel and simultaneous measurements utilizing two different PM samplers along with

particle size distribution and counting equipment

At PM filter loadings from 0 to 400 µg, there was a very good linear correlation between

the SPC and all four Horiba Quad units, as shown in Figure III-11 (a). Filter loadings of

less than 100 µg are most relevant to the LEV III PM emission standards, as they

correspond to emissions at or below 1 mg/mi. The correlation below 100 µg loading

shows slightly greater scatter than the correlation for mass loadings from 0 to 400 µg,

shown in Figure III-11 (b).

26

(a)

(µg)

(b)

Figure III-11. PM filter loading correlation between SPC and Quad units for mass

ranges (a) 0-400 µg and (b) 0-100 µg. (Sardar et al., submitted)

For filter loadings below 100 µg, the percent deviation of the five sampling units is

illustrated in Figure III-12. The majority of the deviations is within ±20%, but is

noticeably higher where the filter loading is below 20 µg (± 40%). The deviation is

relatively stable for measured levels between 20 to 60 µg, and then generally decreases

as the average loading increases.

27

Figure III-12. Percent deviation from average loading for Quad and SPC samplers

(Sardar, et al., submitted)

PM emissions varied substantially across vehicles and test cycles, so “precision” was

calculated as percent variation applicable to emissions from 10 to 60 µg because of the

relevancy to PM emissions at levels of sub 1 mg/mi. A two-way Analysis of Variance

(ANOVA) was used for simultaneous evaluation of equivalency and measurement

precision. Table III-4 shows the ANOVA results. The overall F test for the samplers is

not statistically significant. The p-value (greater than 0.05) also indicated the

equivalence (95% confidence interval) of the five sampler units.

Source of

Variation

SS df MS F P-value F crit

Rows

(Tests)

0.09 20 0.00 0.43 0.98 1.70

Columns

(PM

Monitors)

0.01 4 0.00 0.32 0.87 2.49

Error 0.88 80 0.01

Total 0.99 104

Table III-4. ANOVA table for PM loadings from 10 to 60 µg (Sardar, et al., submitted)

The mean square error (MSE) in Table III-4 (the intersection of the column “MS” and the

row “Error”) is equal to 0.011, an experimental estimate of the “error variance” to which

individual observations are subjected. The root mean square error (RMSE)

28

characterizes the precision of measurement. The precision is determined to be 11.1%.

This value is most appropriate around the 35 µg PM loading (mid-range of 10 to 60 µg

loadings).

Measurement - Repeatability and Reproducibility

Repeatability and reproducibility analyses were performed to evaluate the intra-lab and

inter-lab variability of the measurement systems in ARB’s HSL test cells. The

repeatability of a test cell is defined as the variability that results from repeat tests of the

same vehicle in a short time period under the same sampling conditions (including the

same operator and the same sampling system). Reproducibility is defined as the total

variability that results when different laboratories measure the same vehicle. It is

important to confirm that the results are reproducible between different test cells and

different operators.

One vehicle (Veh 9, a 2009 Nissan Altima in Appendix A2) was repeatedly tested in

three of ARB’s test cells (A, B, and C) to determine repeatability and reproducibility.

The vehicle was chosen because its PM emissions were in the range of interest - below

1 mg/mi. A summary of the PM emission statistics are presented in Table III-5. Of 28

tests in total, two results were above 1 mg/mi. Both of these measurements were

obtained from Test Cell B, which had the highest average emission results.

Cell A

Cell B

Cell C

All Tests

# of Tests

9

8

11

28

Mean

0.67

0.87

0.61

0.70

Standard Error

0.05

0.07

0.05

0.04

Median

0.69

0.86

0.58

0.71

Standard Deviation

0.16

0.19

0.16

0.20

Sample Variance

0.03

0.04

0.03

0.04

Range

0.58

0.62

0.51

0.80

Minimum

0.37

0.56

0.38

0.37

Maximum

0.95

1.17

0.89

1.17

Confidence Level (95%)

0.13

0.16

0.11

0.08

Table III-5. PM emission statistics of vehicle 9 tested in three test cells

The average PM emission rate and tunnel blank values from the three test cells are

shown in the Figure III-13. A set of three tunnel blanks was collected from each test cell

in the morning before each test. The tunnel blank mass was converted to an emission

29

rate using the actual FTP testing conditions (CVS flow = 350 scfm, PM sampler flow = 2

scfm, distance driven = 11.1 miles).

Test Facility

Cell A Cell B Cell C

PM Emisssions Rate, mg/mile

0.0

0.2

0.4

0.6

0.8

1.0

1.2

COV, %

0

5

10

15

20

25

30

PM, mg/mile

TB, mg/mile

COV, %

Figure III-13. PM emission levels (data not corrected for tunnel blank, TB) of vehicle 9.

Error bar represents one standard deviation. (Hu et al., 2014)

The average and one standard deviation of FTP weighted PM emissions in cell A, B,

and C were 0.67 ± 0.16, 0.87 ± 0.19, and 0.61 ± 0.16 mg/mi, respectively. Mean tunnel

blank values were consistently an order of magnitude lower than test results among all

three test cells, with values as follows: cell A (0.04 ± 0.06 mg/mi), cell B (0.06 ± 0.06

mg/mi), and cell C (0.06 ± 0.04 mg/mi). The variability of tunnel blanks was negligible

relative to that of the overall PM measurement. The test results from all three test cells

showed consistent test-to-test variability (CoV=22 to 26%). The range in measured PM

emissions across all three test cells was not a statistically significant difference at the

95% confidence level (Hu et al., 2014).

The intra-lab (test-to-test) variability (

) , inter-lab (lab-to-lab) variability (

), and

reproducibility (

) are calculated by following the statistical analyses equations listed in

the Appendix. The results are shown in Table III-6.

30

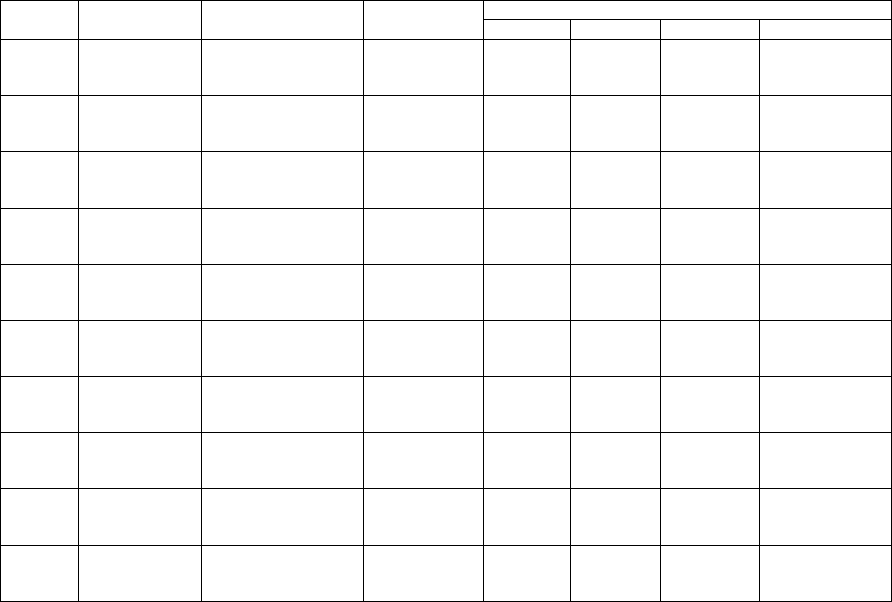

Variability Coefficient of Variance

Emissions Intra- Inter- Total

mg/mile Laboratory

Laboratory

2

Variability

CoV

r

CoV

L

CoV

R

PM 0.70±0.21 0.03 0.01 0.04 0.24 0.17 0.30

Table III-6. Repeatability and reproducibility of one vehicle (Nissan Altima) tested at

three ARB HSL test cells (Hu et al., 2014)

For the vehicle tested in the three cells, the intra-lab variability (

) accounted for 75%

and the inter-lab variability (

) accounted for the remaining 25% of total variability (

,

reproducibility). The dominance of the intra-lab variability was also observed by

Giechaskiel et al. (2008) when measuring particle number emissions of a light-duty

diesel vehicle with diesel particulate filter. The intra-lab variability can be attributed to

the emission source (such as vehicle stability and operator) and tunnel

adsorption/desorption of semi-volatile organic compounds.

d. Equivalency of CFR PM Sampling Options

Equivalency of Single and Three-Filters Sampling Methods

As mentioned in Section II b, 40 CFR Part 1066.815 allows for five different sampling

options. ARB has evaluated the equivalency between two of these options, the

conventional 3 filter FTP and the single filter flow-weighted sampling methods.

The single filter approach is of interest due to its lower cost (reduced number of filters)

and potential for reducing variability, given that much of the variability is associated with

the very low mass loading of phases 2 and 3. For this sampling option (Table III-7,

Option 4), PM is collected on a single filter over the cold-start UDDS cycle and the first

505 seconds of the hot-start UDDS. The sample flow rate is adjusted proportionally to

the filter face velocity over the three intervals of the FTP based on weighting targets of

0.43 for phase 1, 1.0 for phase 2, and 0.57 for phase 3. Filters from the single filter

flow-weighted and conventional 3-filter sampling methods were collected from ARB’s

test cell A using the two collocated samplers illustrated in Figure III-10. Detailed vehicle

information is shown in Appendix Table A-3.

Shown in Table III-7 is a list of eight vehicles and their PM emission levels for evaluating

different sampling methods. An average result from 25 tunnel blanks is also included.

The CoV of the repeated tests is shown in Figure III-14. The CoV of vehicle emission

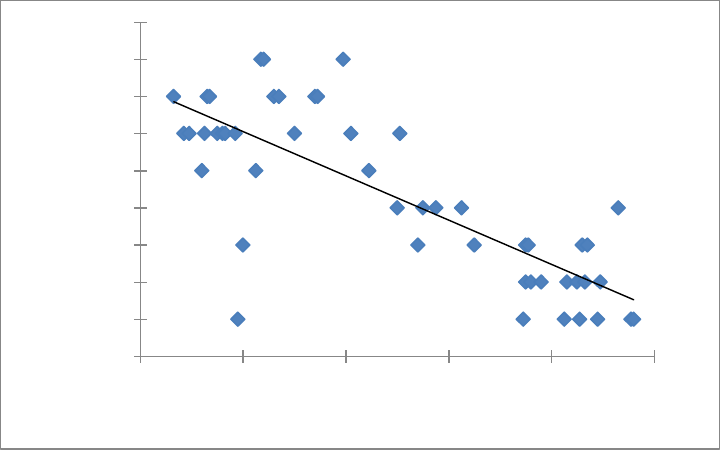

31

repeatability ranges from 1 - 55% and is somewhat inversely related to the emission

rate, in that the high CoV is typically associated with a lower emission rate.

Vehicle Make/Model

Number of Tests

Average PM Emission*

± SD

3 Filter

Single Filter

Honda Civic

12

0.58

±0.13

0.54

±0.11

Chevy Malibu LT

16

0.35

±0.11

0.34

±0.10

Toyota Camry LE

11

0.48

±0.13

0.43

±0.19

Dodge Grand Caravan

12

0.13±0.06

0.11±0.06

Nissan Altima

7

0.90±0.23

0.91±0.20

Honda Accord

3

0.16±0.05

0.15±0.03

Buick Regal

3

3.44±0.08

3.40±0.05

Ford Explorer

3

4.03±0.44

3.81±0.36

Tunnel Blank

25

0.09±0.07

0.04±0.04

*Emission results were not background corrected.

Table III-7. A list of vehicles and their PM emission levels for evaluation of 3-filter and

single-filter-flow-weighted sampling options

Figure III-14. CoV as a function of PM emission rates for the 3-filter and single filter

sampling methods

As shown in Table III-7, the conventional 3-filter and single filter method had

comparable variability despite the lower mass loading with the single filter method. The

benefit of reduced measurement variability with weighing only one filter was offset by

the increased variability at lower mass loading.

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0 1 2 3 4 5

CoV

PM Emissions, mg/mi

3 filter Cov

1 filter CoV

Error bar represents 1 σ

32

The differences in the average PM emissions between the two sampling methods were

found to be less than 10%, with the exception of Dodge Grand Caravan which showed a

deviation of 14%. With the exception of the Nissan Altima, the single filter method has

slightly lower average emission levels compared to the 3-filter method. Bushkuhl et al.

(2013) compared PM mass emissions between the single filter at a constant flow (not

flow-weighted) and the 3-filter method. PM mass from the single filter method was

systematically lower than the sum of the three individual filters used over a FTP cycle.

These differences might be attributed to an increase in total organic compound

adsorbed when using more filters.

The correlation between the single and 3-filter methods (without background correction)

is depicted in Figure III-15 (a) for vehicular PM emissions below 3.5 mg/mi. The R

2

value of 0.99 indicates a very high degree of correlation between these two methods.

Figure III-15 (b) depicts the correlation of vehicle PM emission levels in the sub 1 mg/mi

range. The scatter increases slightly with an R

2

of 0.92.

To further investigate the anomaly of PM levels determined by the two methods, the sub

1 mg/mi PM mass data were corrected by subtracting the average tunnel blank PM

mass for each filter. The average tunnel blank PM loadings for phases 1, 2, and 3, and

for the single flow-weighted filter are found to be 2.0, 2.1, 2.2, and 1.9 µg, respectively.

Figure III-15 (c) shows the correlation between the two methods after the background

correction. The background correction improves the R

2

slightly to 0.94 and the slope

noticeably to 0.98.

A statistical analysis (paired t-test) was also performed for the background (tunnel

blank) corrected emission data. Results of the paired t-test at the 95% confidence level

(α=0.05) indicated no statistically significant difference between these two methods.

33

(a)

(b)

(c)

34

Figure III-15. Single and 3-filter method comparison: (a) For emission levels between 0

and 3.5 mg/mi; (b) For emission levels less than 1 mg/mi range without background

correction, and (c) Emission levels less than 1 mg/mi with background corrections

(Sardar et al., submitted)

Equivalency of Three- and Two-Filters Sampling Methods

ARB also evaluated a two-filter method, 40 CFR Part 1066.815 Option 2, by collecting

PM on one filter over the cold-start UDDS and on a separate filter over the hot-start

UDDS. However, only one vehicle (Nissan Altima) was tested for this sampling option.

A total of 7 paired samples for the 2-filter and conventional 3-filter methods were

collected. The results of these two methods for this vehicle are equivalent at an

emission level of 1 mg/mi. The PM emission rates for 2-filter and 3-filter were 0.94 ±

0.15 and 0.96 ± 0.14 mg/mi, respectively.

Partial Flow Dilution (PFD) for PM Sampling

EPA’s CFR Part 1065 Engine Test Procedures and Part 1066 Vehicle Test Procedures

permit an option for diluting exhaust either through a full flow CVS or a partial flow

dilution (PFD) sampling system prior to PM collection. PFD sampling dilutes only a

fraction of raw exhaust, which reduces the flowrate of dilution air needed but requires a

real-time exhaust flow signal to maintain the proportionality of dilution air.

A study by Khalek (2007) on diesel particulate measurement evaluated five different

PFD units for heavy duty engine testing. All of the PFD units demonstrated good

sample flow response times (on the order of 100 ms), and most had excellent

correlation between the sample flow and the exhaust flow with R

2

exceeding 0.99 and a

standard error <5%. Using a diesel particulate filter with continuous regenerative

technology and a bypass, the PM mass emission measurements from four out of five

PFD units showed that they performed well under steady-state engine operation.

However, three of five PFD units reported higher PM mass emission levels under

transient engine operation.

Though heavy duty PFDs have been evaluated for quite some time now, little has been

done to evaluate the applicability of PFD’s in LDV emissions. Two prototype PFD’s

have been evaluated for LDV application (Foote et al., 2013). Both prototype PFDs

were able to meet the flow proportionality requirements for traditional powertrains, but

not for hybrid electric vehicle (HEV) powertrains due to intermittent zero flow conditions.

The weighted PM emissions of the two PFDs and the CVS full flow dilution correlate

linearly when emissions were less than 3 mg/mi, yielding slopes of 1.03 and 0.74 with

R

2

of 0.95 and 0.86, respectively. The scatter increased when emissions were less

than 1 mg/mi, yielding R

2

of 0.58 and 0.38. Improvements to PFDs are still needed

when measuring emissions less than 1 mg/mi.

A partial dilution system can potentially add flexibility to compliance testing. However,

ARB currently has no such capability and will continue to evaluate the applicability of

PFDs in emission testing.

35

IV. ALTERNATIVE METRICS FOR PARTICULATE MASS DETERMINATION

Vehicle PM emissions are a physically and chemically complex heterogeneous mixture

comprised of solid, liquid, semi-volatile, and gaseous compounds that are a byproduct

of incomplete combustion and have been recognized as a significant anthropogenic

source of ambient PM.

The characterization of PM emissions can be complex and challenging. Over the past

two decades, considerable progress has been made in both sampling and

measurement methodologies for determining a variety of physical and chemical

properties of PM, such as particle number, size distribution, and black carbon. Methods

that can measure ambient and source samples, including aerosol gravimetric

determination, are of great interest. Commonly used instruments for measuring particle

number, size distribution, and black carbon of vehicle PM emissions are described in

the Appendix along with their operating principles and capabilities.

Part of the complexity of measuring particle emissions relates to the transformations

that take place as the particles are emitted from the tailpipe at a high temperature, and

then measured after dilution and cooling in order to simulate its immediate formation in

ambient air. Figure IV-1 provides a simplified overview of the particle transformation

process, starting from a vehicle and ending at the measurement instruments, which are

connected to the CVS dilution tunnel to determine PM mass and particle number (PN)

emissions (Giechaskiel et al., 2014). The primary soot particles (typically small

spherules) form in the combustion chamber. After exiting the tailpipe and the transfer

tube and entering the CVS tunnel, soot particles agglomerate whereas semi-volatile

organic compounds either nucleate (both heterogeneously and homogeneously) or

condense onto soot particles. As they are transported through the dilution tunnel, there

can be a tri-modal size distribution with nucleation, accumulation, and coarse modes, as

shown in the upper left corner of Figure IV-1.

Typical PN and PM mass distributions for an uncontrolled diesel engine emission are

shown in Figure IV-2 (Kittelson, 1998). Although the nucleation mode particle number

concentration is high, the PM mass is much less compared to the accumulation mode.

36

Figure IV-1. Typical sequence of particle transformation from the engine to the

measurement location (modified from Giechaskiel et al., 2012)

Figure IV-2. Typical engine exhaust size distribution for both PM mass and PN

(Kittelson, 1998)

The relationship of total particle number and PM mass emissions for LDVs were

examined with TSI Engine Exhaust Particle Sizer (EEPS) measurements between 5.6

and 560 nm and filter-based gravimetric mass measurements. Based on a dataset with

more than 150 FTP tests from 34 LDVs, a correlation between total particle number and

PM mass is presented in Figure IV-3. In this analysis, the particle number to mass ratio

37

for different vehicle technologies was found to be 2.8 x 10

12

particles/mg (PFI vehicles),

1.6 x 10

12

particles/mg (GDI vehicles), and 8.7 x 10

11

particles/mg (Diesel Particulate

Filter (DPF) equipped Light Duty Diesel (LDD) vehicles), respectively. The data

demonstrate that, per unit mass, conventional PFI gasoline vehicles emit a greater

number of particles than GDI vehicles.

Figure IV-3. Scatter plots for total particle number versus gravimetric PM mass (Quiros

et al., 2015b)

Figure IV-4 presents the average particle number emission rates calculated using the

EEPS data. Data are presented for (a) vehicles meeting the 1 mg/mi standard and (b)

vehicles meeting the 3 mg/mi standard. The majority of the particle number emissions

for all classifications of LDVs were in the sub-100 nm range (usually referred to as

ultrafine particles (UFP)). A smaller but still significant fraction of total particle number is

within the sub-23 nm size fraction: 28% when numerically averaged over all tests

plotted in Figure IV-3. As noted earlier, the sub-23 nm size particles are of interest

38

because the current EU particle number standards only count particles with a diameter

greater than 23 nm. The EU method for measuring solid particle number (SPN) >23 nm

was also evaluated using most of the same dataset, and is presented and discussed in

the following section.

(a)

(b)

Figure IV-4. Total number emissions (a) for vehicles meeting the 1 mg/mi standard

(n=115) and (b) for vehicles meeting the 3 mg/mi standard (n=152) (Quiros et al.,

2015b)

a. PMP Method: Solid Particle Number Measurement

Based on

the recommendation of the Particle Measurement Programme (PMP), the

European Union introduced an SPN standard as a supplemental limit to PM mass in

Euro 5/6 (United Nation’s Economic commission for Europe (UN-ECE) regulation 83) for

direct injection vehicles (GDI and diesel).

The Particle Measurement Programme was launched in 2001 under the auspices of the

UN-ECE Group of Experts on Pollution and Energy (GRPE). The program was

designed to deliver a regulatory procedure for Europe that would either replace or

complement the existing method used for PM mass measurement for vehicle

certification. Based on the inter-laboratory correlation results

(Andersson et al., 2007),

the program showed that the PM mass measurement was feasible and that a SPN-

based limit was also able to distinguish between the emission regimes of various

technologies. It provided the scientific basis for the Euro 5/6 limits for particle number

and PM mass for EU type approval.

The SPN measurement requires a particle number measurement system, consisting of

a Volatile Particle Remover (VPR) and a Particle Number Counter (PNC) that measures

39

particles with a diameter greater than 23 nm. The specifications of the SPN system are

shown in Figure IV-5. When the exhaust enters the VPR, it is heated up to 300-400

o

C,

the temperature at which most of the volatiles and semi-volatiles evaporate. The

nucleation mode particles, when they are dominated by volatiles and semi-volatiles, are

reduced significantly. Two other methods, based on the principles of adsorption on

activated carbon or oxidation by catalytic stripper, can also be utilized to remove volatile

components (Giechaskiel et al., 2014). From a practical standpoint, commercial SPN

systems use the evaporation method. The particle number counter, such as CPC,

measures particles with a counting efficiency of 50% and >90% at 23 and 41 nm,

respectively. Unlike the gravimetric method validation with a known traceable metal

weight, calibration of the PMP method is based on measurement comparisons to a

reference instrument rather than measurement of a known calibration standard. GRPE

is working on further refinements including the development of a calibration procedure

based on an ISO test method (27891:2015) which uses an electrometer for instrument

calibration. Figure IV-1 (upper right corner) illustrates the PMP method for particle

number measurement. Compared to the total particle number results, the nucleation

mode particles are almost completely excluded by this method.

Figure IV-5. Description of solid particle sampling protocol (B. Giechaskiel, and G.

Martini, 2013)

The key goal of the PMP is to achieve repeatable emission results, especially since the

method would be used for certification testing. To improve measurement repeatability,

40

the PMP method requires removal of volatile/semi-volatile compounds, which can be

heavily influenced by the sampling conditions.

Research conducted at the Joint Research Center (JRC in Ispra, Italy) has concluded

that 20 to 40% of particles emitted from GDI vehicles are smaller than 23 nm

(Giechaskiel and Martini, 2013). It has been shown that solid particles with smaller

sizes can be also measured with good repeatability (Herner et al., 2007). In recognition

of sub-23 nm solid particles in LDV exhaust, JRC is investigating the feasibility of

lowering the 23 nm cutpoint (Giechaskiel and Martini, 2013). The performance of PNCs

and VPRs for the standard PMP method was systematically evaluated for the purpose

of extending measurements to sub-23nm solid particles. The investigation concluded

that extending SPN measurement to ~10 nm may be possible, with a recommended

addition of a catalytic stripper (CS). However, certain outstanding issues would need to

be resolved.