Instruction manual

FLOW-SMS series

Surface Mount System for Digital

Mass Flow / Pressure

Meters and Controllers

Doc. no.: 9.17.057N Date: 20-09-2021

ATTENTION:

Please read this instruction manual carefully before installing and operating the instrument.

Not following the guidelines could result in personal injury and/or damage to the equipment.

Bronkhorst

®

9.17.057

page 2

Disclaimer

Even though care has been taken in the preparation and publication of the contents of this manual, we do not assume

legal or other liability for any inaccuracy, mistake, mis-statement or any other error of whatsoever nature contained

herein. The material in this manual is for information purposes only, and is subject to change without notice.

Symbols

Important information. Discarding this information could cause injuries to people or damage to the

Instrument or installation.

Helpful information. This information will facilitate the use of this instrument.

Additional info available on the internet or from your local sales representative.

Receipt of equipment

Check the outside packing box for damage incurred during shipment. Should the packing box be damaged, then the

local carrier must be notified at once regarding his liability, if so required. At the same time a report should be

submitted to your distributor.

Carefully remove the equipment from the packing box. Verify that the equipment was not damaged during shipment.

Should the equipment be damaged, then the local carrier must be notified at once regarding his liability, if so

required. At the same time a report should be submitted to your distributor.

Before installing an FLOW-SMS System it is important to read the attached labels and check:

- Flow rate(s) / Pressure rate(s)

- Fluid(s) to be measured

- Up- and downstream pressures

- Input/output signals

- Temperature

Do not discard spare or replacement parts with the packing material and inspect the contents for

damaged or missing parts.

Refer to chapter 6 about return shipment procedures.

Equipment storage

The equipment should be stored in its original packing in a cupboard warehouse or similar. Care should be taken not

to subject the equipment to excessive temperatures or humidity.

Bronkhorst

®

9.17.057

page 3

Warranty

The products of Bronkhorst® are warranted against defects in material and workmanship for a period of three years

from the date of shipment, provided they are used in accordance with the ordering specifications and the instructions

in this manual and that they are not subjected to abuse, physical damage or contamination. Products that do not

operate properly during this period may be repaired or replaced at no charge. Repairs are normally warranted for one

year or the balance of the original warranty, whichever is the longer.

See also paragraph 9 of the Conditions of sales:

http://www.bronkhorst.com/files/corporate_headquarters/sales_conditions/en_general_terms_of_sales.pdf

The warranty includes all initial and latent defects, random failures, and undeterminable internal causes.

It excludes failures and damage caused by the customer, such as contamination, improper electrical hook-up, physical

shock etc.

Re-conditioning of products primarily returned for warranty service that is partly or wholly judged non-warranty may

be charged for.

Bronkhorst High-Tech B.V. prepays outgoing freight charges when any party of the service is performed under

warranty, unless otherwise agreed upon beforehand. However, if the product has been returned collect to Bronkhorst

High-Tech B.V., these costs are added to the repair invoice. Import and/or export charges, foreign shipping

methods/carriers are paid for by the customer.

Bronkhorst

®

9.17.057

page 4

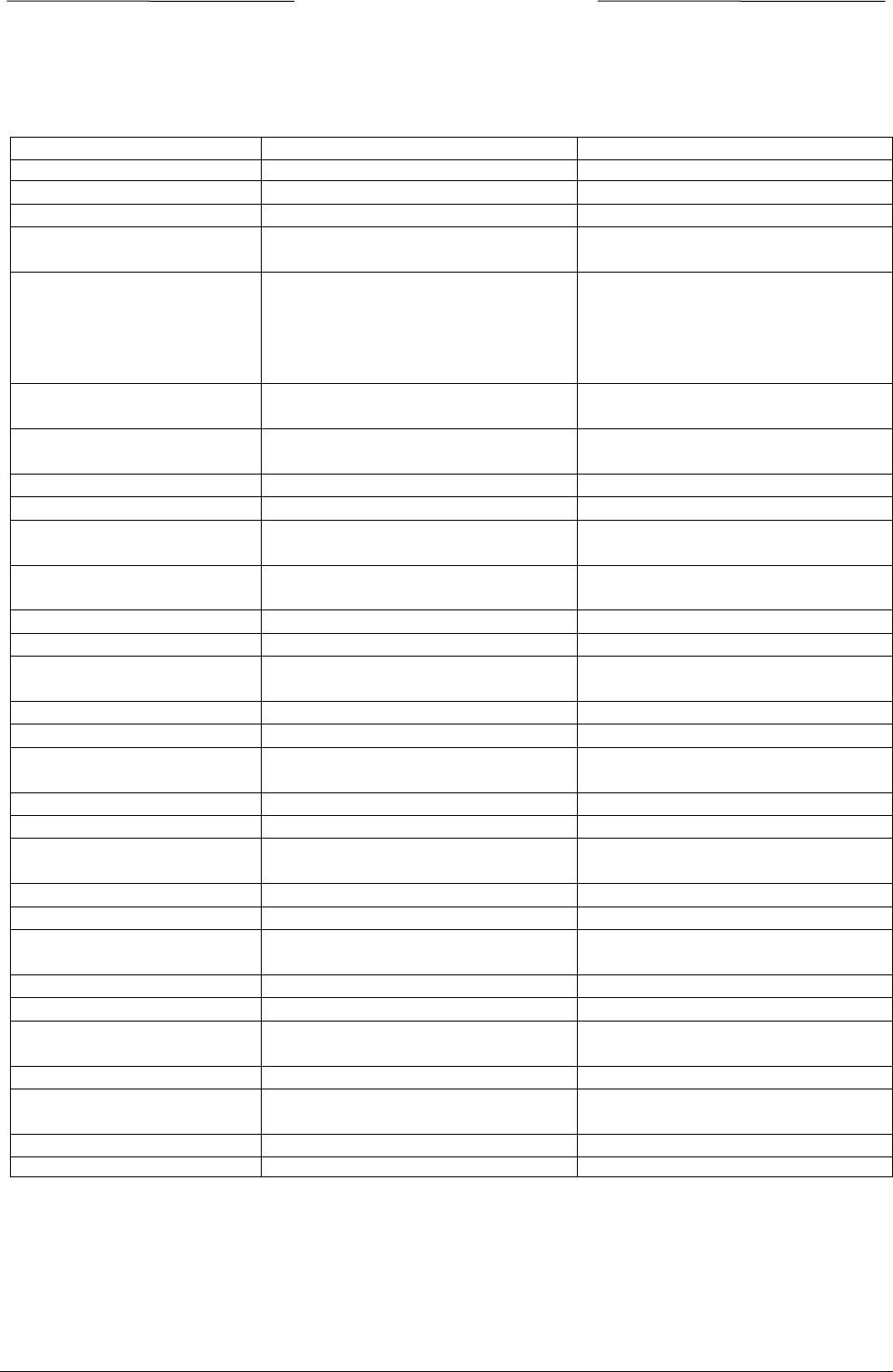

Table of contents

1 SCOPE OF THIS MANUAL ............................................................................................................................... 5

1.1 Introduction ......................................................................................................................................................... 5

1.2 References to other applicable documents ......................................................................................................... 5

2 STARTING UP ................................................................................................................................................ 6

2.1 Check properties .................................................................................................................................................. 6

2.2 Rated pressure test inspection ............................................................................................................................ 6

2.3 Check piping......................................................................................................................................................... 6

2.4 Install system ....................................................................................................................................................... 7

2.5 Leak check............................................................................................................................................................ 7

2.6 Electrical connection ........................................................................................................................................... 7

2.7 Analog / Digital operation ................................................................................................................................... 8

2.8 Multi-functional switch operation ....................................................................................................................... 8

2.9 Purging ................................................................................................................................................................. 8

2.10 Zeroing ................................................................................................................................................................. 9

2.11 Calibration ........................................................................................................................................................... 9

2.12 Supply pressure ................................................................................................................................................... 9

2.13 Description ........................................................................................................................................................... 10

2.13.1 Introduction ......................................................................................................................................................... 10

2.13.2 Functional modules ............................................................................................................................................. 10

2.13.3 Flow modules ....................................................................................................................................................... 10

2.13.4 Pressure modules ................................................................................................................................................ 11

2.13.5 Solenoid Operated shut off valves ....................................................................................................................... 13

2.13.6 Toggle valves........................................................................................................................................................ 13

2.13.7 Needle valves ....................................................................................................................................................... 14

2.13.8 Pneumatic operated shut off valves .................................................................................................................... 14

2.13.9 Pneumatic operated shut off 3/2 valves ............................................................................................................. 16

2.13.10 Filter modules ...................................................................................................................................................... 16

2.13.11 Blind/Flow plates ................................................................................................................................................. 17

2.14 Model key ............................................................................................................................................................ 18

3 BASIC OPERATION ......................................................................................................................................... 19

3.1 General ................................................................................................................................................................ 19

3.2 Analog operation ................................................................................................................................................. 19

3.3 Manual interface: micro-switch and LED’s .......................................................................................................... 19

3.4 RS232 FLOW-BUS operation ................................................................................................................................ 19

3.5 Fieldbus operation ............................................................................................................................................... 21

4 ADVANCED OPERATION ................................................................................................................................ 22

4.1 Using mass flow meters/controllers on different gases or under different conditions ...................................... 22

4.1.1 Stored calibration curves ..................................................................................................................................... 22

4.1.2 Multi Fluid / Multi Range instruments ................................................................................................................ 22

4.1.3 Conversion factor calculation using Fluidat software.......................................................................................... 22

4.1.4 Sealing material ................................................................................................................................................... 22

4.1.5 Maximum pressure drop ..................................................................................................................................... 23

5 TROUBLESHOOTING AND SERVICE ................................................................................................................ 24

5.1 General ................................................................................................................................................................ 24

5.2 LED indication ...................................................................................................................................................... 24

5.3 Troubleshooting summary general ...................................................................................................................... 25

5.4 Service ................................................................................................................................................................. 26

6 REMOVAL AND RETURN INSTRUCTIONS ....................................................................................................... 27

Bronkhorst

®

9.17.057

page 5

1 Scope of this manual

1.1 Introduction

This manual covers the FLOW-SMS series, Bronkhorst® lightweight, modular gas delivery system. It handles the

general instructions needed for the surface mount components, i.e. digital mass flow / pressure meters and

controllers, control valves, shut-off valves and filters, as well as the manifold components such as mixing and

distribution chambers, support rails and adapter plates.

FLOW-SMS systems are assembled according to customer’s specifications. The ranges for the flow sensor can be

selected between approx. 5 ml

n

/min up to 50 l

n

/min or even higher. In case a pressure sensor is included, the

pressure range can be chosen between 0-100 mbar and 0-10 bar absolute or gauge. Depending on the application

the customer may prefer a system with face seal fittings, compression type couplings, or flanges according to

customers’ specification. On request, the system will be assembled, tested, and packaged in a cleanroom.

Example:

1.2 References to other applicable documents

FLOW-SMS instruments have modular instruction manuals consisting of:

- FLOW-SMS series (document nr. 9.17.057)

- Operation instructions digital instruments (document nr. 9.17.023)

- Optional fieldbus/interface descriptions:

- FLOW-BUS interface (document nr. 9.17.024)

- PROFIBUS

DP interface (document nr. 9.17.025)

- DeviceNet

TM

interface (document nr. 9.17.026)

- RS232 interface with FLOW-BUS protocol (document nr. 9.17.027)

- Modbus interface ASCII / RTU / TCP (document nr. 9.17.035)

- EtherCAT interface (document nr. 9.17.063)

- PROFINET interface (document nr. 9.17.095)

- CANopen interface (document nr. 9.17.131)

- EtherNet/IP interface (document nr. 9.17.132)

- POWERLINK interface (document nr. 9.17.142)

- Hook-up diagrams for analog, RS232 and fieldbus operation

- Dimensional drawing (document nr. 7.05.813)

These documents, except for the dimensional drawing, can be found in PDF format on the CD

“Documentation and software tools”, furnished with the delivered instruments. The documents are

also available on:

http://www.bronkhorst.com/en/downloads

or can be applied for at our local sales & service representatives

Bronkhorst

®

9.17.057

page 6

2 Starting up

2.1 Check properties

Before installing a FLOW-SMS system it is important to

read the attached labels and check:

- Flow rates / Pressure rate(s)

- Fluids to be measured

- Up- and downstream pressures

- Input/output signal

- Temperature

Check if the sealing material like O-rings, plunger and packing gland of capillary are suitable for the

used gas and process. The Flow module is fitted with Viton, EPDM or Kalrez seals. Which sealing

material is used is shown in the last character of the model key. The rest of FLOW-SMS system also

contains sealings, which are selected based on the fluid flow schematic diagram.

2.2 Rated pressure test inspection

Each FLOW-SMS system is pressure tested to at least 1.5 times

the working pressure of the process conditions stipulated by the customer,

with a minimum of 8 bar.

Pressure Testing Sticker

Each instrument is helium leak tested to at least 2

⋅

10-9 mbar l/s Helium

outboard.

2.3 Check piping

For reliable measurement always make sure the fluid stream is clean.

Use filters to assure a moisture-, oil- and particle-free gas stream.

Recommended pore-size: 7 µm.

If back flow can occur, a downstream filter and a check valve are

recommended too.

For particle filtering the FLOW-SMS program offers sintered filter modules

with porosities 0.5, 2, 7, and 15 micron

The tested pressure is stated on the instrument with a RED COLOURED sticker. Before installation, make

sure that the test pressure is in accordance with normal safety factors for your application.

If there is no Pressure Testing Sticker on the device or if the test pressure is incorrect, the instrument

should not be mounted in the process line and be returned to the factory.

input/output

A – 0…5 Vdc

B – 0…10 Vdc

F – 0…20 mA

G – 4…20 mA

Bronkhorst

®

9.17.057

page 7

2.4 Install system

Install the FLOW-SMS assembly in accordance with the

directions following the schematic diagram.

Tighten the fittings according to the instructions.

For compression type adapters, slide the nut and the ferrule

set in the right order at the tube. Insert the tubing fully into

the Adapter plate against the shoulder. Rotate the nut finger-

tight, while holding the fitting body steady. Tighten the nut

three quarters clockwise for the fittings up to 4 mm and

3/16” tube OD. For larger fittings, tighten the nut one and one-quarter.

For metal and o-ring face seal type, rotate the nut finger-tight, than turn the nut one-quarter

clockwise, which is sufficient for the sealing. When the Adapter Plate

is replaced the complete

module has to be tested for leakage and function.

The preferred mounting position of mass flow or pressure meters/controllers is horizontal. Other

mounting positions may introduce a zero shift and/or little gas and pressure dependency of the zero

signal. When mounting the assembly other than horizontal, zeroing of the instruments is advised. The

zeroing procedure is described in paragraph 2.10.

Avoid installation in close proximity of mechanic vibration and/or heat sources.

2.5 Leak check

Check the system for leaks before applying (fluid) pressure. Especially if toxic, explosive or other

dangerous fluids are used!

2.6 Electrical connection

Electrical connections must be made with standard cables or according to the applicable hook-up

diagrams. These documents can be found at:

http://www.bronkhorst.com/en/downloads

Please note that FLOW-SMS instruments are rated IP40, implying that the electronics housings and

electrical connections do not offer any protection against moist environments.

The instruments contain electronic components that are susceptible to damage by electro static

discharge. Proper handling procedures must be taken during installation, removing and connecting the

electronics.

All instruments described in this manual carry

the CE-mark and are compliant with the EMC

requirements. However compliance with the

EMC requirements is not possible without the

use of proper cables and connector/gland

assemblies. For good results Bronkhorst®

can provide standard cables.

Otherwise follow the guidelines as stated

hereby.

Bronkhorst

®

9.17.057

page 8

When connecting the system to other devices (e.g. to PLC), be sure that the integrity of the shielding is

not affected. Do not use unshielded wire terminals.

Operation via fieldbus is done by means of a flat conductor

cable connected with the main PC board.

Although all functionality is possible by means of RS232

and the switch on top of the instrument, it is important

that care should be taken when removing the upper part

of the housing.

In case that a shut-off valve is mounted directly behind a control

module, please apply a right angled connector for Analog/RS232

communication.

2.7 Analog / Digital operation

2.7a Analog/Local operation

Connect the Mass Flow or Pressure Meter/Controller

to the power supply/readout unit using a cable with

9-pin sub-D connector.

2.7b Digital/Fieldbus operation

For this procedure see description for RS232 or the applicable

fieldbus operation.

RS232 connection cable 7.03.366 enables to use (free)

Bronkhorst® tooling programs for Windows

2.8 Multi-functional switch operation

Using the 2 colored LEDs and the switch on the instruments,

several actions can be monitored and started. The green LED

is used for status indication. The red LED is used for errors/

warnings/messages. The switch can be used to start several

actions, such as auto-zero, restore factory settings and bus-

initialization actions, if applicable.

See specific zero-procedure below (10) for more details.

Error/warning LED

Status LED

Multifunctional

switch

EXAMPLE

Power:

+15...+24 Vdc

Analog input / output:

0…5Vdc / 0…10Vdc

0…20mA / 4…20mA

7.03.366

Bronkhorst

®

9.17.057

page 9

2.9 Purging

In systems for use with corrosive or reactive fluids, purging for at least 30 minutes with a dry, inert gas

(like Nitrogen or Argon) is absolutely necessary before use. After use with corrosive or reactive fluids,

complete purging is also required before exposing the system to air.

Warm-up time:

Let the instruments warm-up for at least 30 minutes for best accuracy.

During warm-up period, fluid pressure may either be on or off.

2.10 Zeroing

The zero-point of each instrument is factory adjusted. If so required the zero point may be re-

adjusted over RS232 or fieldbus or by means of using the micro switch. Procedure for zeroing by

micro switch:

♦

Warm-up, pressure up the system and fill the instrument according to the process

conditions.

♦

Make sure no flow is going through the instrument by closing valves near the instrument.

♦

The setpoint must be zero.

♦

Press micro switch and hold it. After a short time the red LED will go ON and OFF, then the

green LED will go ON. At that moment release the micro switch.

♦

The zeroing procedure will start at that moment and the green LED will blink fast. The

zeroing procedure waits for a stable signal and saves the zero. If the signal is not stable,

zeroing will take long and the nearest point to zero is accepted. The procedure will take

approx. 10 seconds.

When the indication is showing 0% signal and the green indication LED is burning continuously again,

then the zeroing action was successful.

2.11 Calibration

Each FLOW-SMS instrument is factory calibrated. Calibration certificates are included in the shipment. When operated

properly (clean gases, no pressure shocks, no vibrations, no thermal shocks, etc), regular maintenance is not required.

However, periodical inspection, recalibration or verification of the accuracy may be subject to individual requirements

of the end-user. Please refer to the internal operational requirements of your company.

2.12 Supply pressure

It is recommended to turn on power before applying pressure on the instrument and to switch off

power after removing pressure.

Turn on fluid supply gently. Avoid pressure shocks and bring the instrument gradually up to the level of

the actual operating conditions. Also switch off fluid supply gently.

Bronkhorst

®

9.17.057

page 10

2.13 Description

2.13.1 Introduction

FLOW-SMS systems are compact mounting rail assemblies,

containing one or more mass flow or pressure sensor

modules, that can be combined with control valves,

shut-off valves, mixing chambers, filters or any other

functional module as per customer's request.

Also the manifold on which the functional modules are

mounted consists of a modular assembly of support rails,

base bodies and adapter or blind plates.

2.13.2 Functional modules

The pictures on the right side illustrate the modular concept

of the FLOW-SMS system. It offers great flexibility for the end-user

with respect to modifications and serviceability. The functional

modules are ‘top-mount’, so they can easily be exchanged without

removing the total assembly.

In the following paragraphs we have laid down the instructions

for removal and replacement of functional modules.

Bronkhorst® recommends to clean or to replace gaskets and hexagon bolts before reassembling

functional modules.

FLOW-SMS manifold components (base bodies, distribution and mixing chamber, etc.) should only be

removed or replaced by qualified personnel.

2.13.3 Flow modules

- General information

The gas flow sensor operates on a principle of heat transfer by

sensing the temperature difference along a heated section of

a capillary tube. Part of the total flow is forced through the

capillary by means of a laminar flow element in the main stream

generating a pressure difference. The design of the laminar flow

device is such that flow conditions in both the capillary and

laminar flow device are comparable, thereby resulting in

proportional flow rates through the meter. The ΔT sensed by the

upstream and downstream temperature sensors on the capillary

depends on the amount of heat absorbed by the gas flow.

Each instrument has been calibrated and adjusted for customer process conditions. The performance

and accuracy may be affected tremendously if physical fluid properties such as heat capacity and

viscosity change due to changing process conditions. For operation on other gases see paragraph 4.1.

Bronkhorst

®

9.17.057

page 11

The control valve used in the FLOW-SMS series is a standard, direct

operated solenoid valve (normally opened or normally closed),

operated through the PID-control function on the pc-board of the

flow or pressure meter. The diameter of the orifice under the

plunger is optimised for the customer’s specification.

Controllers or valves may not operate correctly, if process conditions vary too much, because of the

restriction of the orifice in the valve.

Instructions for replacing a Mass Flow Meter (MFM) or

Mass Flow Controller (MFC) module:

- Removal

Ensure that the system is depressurised before taking Flow

module apart.

The power must be off when removing the electrical connectors.

Loosen the 4 bolts (M4) with hexagon head counter clockwise to

release the Flow module.

- Replacement

Replace the gaskets depending on the type: FS-200CV 2xAS-108,

FS-201CV 1xAS-115 and 1xAS-108, FS-202CV 1xAS-118 and 1xAS-108.

Viton, EPDM or Kalrez.

All wetted parts have to be absolutely clean, don’t use oil or

grease and avoid dust!

Replace the Flow module and tighten the M4 bolts with hexagon

head by turning clockwise, tighten crosswise with 2,0 Nm.

Reattach the electrical connector.

Now the Flow module has to be tested for leakage and function.

Available Mass Flow Controller / Mass Flow Meter modules

Type

Type

Nominal

Range

Description

Controller (MFC)

Meter (MFM)

Range (based on N2@ 1 bara

FS-200CV

FS-100C

005

0.06…3 up to 0,18…9 mln/min

FS-201CV

FS-101C

020

0.16…8 up to 0,6…30 mln/min

FS-201CV

FS-101C

050

0,4…20 up to 1,5…75 mln/min

FS-201CV

FS-101C

100

0,8…40 up to 3…150 mln/min

FS-201CV

FS-101C

200

1,6…80 up to 6…300 mln/min

FS-201CV

FS-101C

500

4…200 up to 15…750 mln/min

FS-201CV

FS-101C

1k0

8…400 up to 30…1500 mln/min

FS-201CV

FS-101C

2k0

16…800 up to 60…3000 mln/min

FS-201CV

FS-101C

5k0

0,04…2 up to 0,15…7,5 ln/min

FS-201CV

FS-101C

7k0

0,05…2.6 up to 0,2…10 ln/min

FS-202CV

FS-102C

10k

0.08…4 up to 0.3…15 ln/min

FS-202CV

FS-102C

20k

0,16…8 up to 0.6…30 ln/min

FS-202CV

FS-102C

35k

0,25…12.5 up to 1…50 ln/min

2.13.4 Pressure modules

FLOW-SMS pressure meters/controllers range from 100 mbar up to 10 bar,

measuring either absolute pressure or gauge pressure, with a very high accuracy

and repeatability. The instruments are equipped with a diaphragm based

piezo-resistive sensor. Pressure controllers are available as forward controller

(P-600 series) and backward controller (P-700 series).

The flow going through the pressure controller depends on up and downstream

pressures, orifice diameter of the valve and the density of the fluid.

MFC

MFM

Bronkhorst

®

9.17.057

page 12

The control valve used in the FLOW-SMS series is a standard, direct

operated solenoid valve (normally opened or normally closed),

operated through the PID-control function on the pc-board of the

flow or pressure meter. The diameter of the orifice under the

plunger is optimised for the customer’s specification.

Instructions for replacing a Pressure Meter (PM) or

Pressure Controller (PC) module:

- Removal

Ensure that the system is depressurised before taking

Pressure module apart.

The power must be off when removing the electrical connectors.

Loosen the 4 bolts with hexagon head counter clockwise to

release the Pressure module.

- Replacement

Replace the gaskets 2xAS-108, Viton, EPDM

or Kalrez.

All wetted parts have to be absolutely clean, don’t use oil or

grease and avoid dust!

Replace the Pressure module and tighten the M4 bolts with hexagon

head by turning clockwise, tighten crosswise with 2,0 Nm.

Replace the electrical connector.

Now the Pressure module has to be tested for leakage and

function.

Available Pressure Controller / Pressure Meter modules

Pressure Module

Description

Model number

Function

Smallest range

Highest range

PS-502C

Meter

2..100 mbar

0,2…10 bar

PS-602CV-NC

Controller forward (NC)

5..100 mbar

0,5…10 bar

PS-702CV-NC

Controller back (NC)

20…100 mbar

2…10 bar

Pressure range (FS)

Indentification in model key

(bar)

Absolute

Relative

0,1 - 0,35

350A

350R

0,35 - 1,1

1k1A

1k1R

1,1 - 6,0

6k0A

6k1R

6,0 – 21

21kA

21kR

Please keep in mind that the pressure rating for FLOW-SMS is 10 bar only.

In pressure control systems the system widely determines the response behaviour of the control loop.

During testing the customer system is simulated as closely as possible. In some cases however

readjustment is needed for optimum performance under actual conditions.

Bronkhorst

®

9.17.057

page 13

2.13.5 Solenoid Operated shut off valves NC and NO

- Removal

Ensure that the system is depressurised before taking shut off

valve apart.

The power must be off when removing the electrical connectors.

Remove the coil by releasing the clip on top of the coil for the

normally closed, and the nut for the normally opened.

Loosen the 2 bolts with hexagon head counter clockwise to

release the valve.

- Replacement

Replace the gaskets AS-007 and AS-017, Viton, EPDM

or Kalrez.

All wetted parts have to be absolutely clean, don’t use oil or

grease and avoid dust!

Replace the shut off valve and tighten the bolt with hexagon

head by turning clockwise, tighten crosswise with M3 0,9 Nm.

Replace the coil and replace the clip on top of the coil normally

closed, and the nut for the normally opened.

Replace the electrical connector.

Now the shut off valve has to be tested for leakage and function.

2.13.6 Toggle valves

- Removal

Ensure that the system is pressure less before taking

the toggle valve apart.

Loosen the 4 bolts with hexagon head counter clockwise

to release the toggle valve.

- Replacement

Replace the gaskets AS-007 and AS-017, Viton,

EPDM or Kalrez.

All wetted parts have to be absolutely clean, don’t use

oil or grease and avoid dust!

Replace the toggle valve centre before tighten the bolt

with hexagon head by turning clockwise, tighten crosswise

with M3 0,9 Nm.

Now the toggle valve has to be tested for leakage and function.

Available electric shut off valves

Model number

Description

EV-02-NC-V(iton)

Kv=0,065

Max deltaP 3 bar

EV-02-NC-E(PDM)

Kv=0,065

Max deltaP 3 bar

EV-02-NC-K(alrez)

Kv=0,065

Max deltaP 3 bar

EV-02-NO-V(iton)

Kv=0,065

Max deltaP 3 bar

Available Toggle valves

Model number

Description

TV-01-V

Kv=0,09

Toggle Valve with Viton seals

TV-01-E

Kv=0,09

Toggle Valve with EPDM seals

TV-01-K

Kv=0,09

Toggle Valve with Kalrez seals

Hook- up solenoid operated valve.

Supply voltage + 24Vdc

Power consumption 3 Watt.

Solenoid

valve coil

VDR

LED

Connector

1

2

Bronkhorst

®

9.17.057

page 14

2.13.7 Needle Valves

- Removal

Ensure that the system is depressurised before taking the

needle valve apart.

Loosen the 4 bolts with hexagon head counter clockwise

to release the needle valve.

- Replacement

Replace the gaskets AS-007 and AS-017,Viton,

EPDM or Kalrez.

All wetted parts have to be absolutely clean, don’t use oil

or grease and avoid dust!

Replace the needle valve centre before tighten the bolt

with hexagon head by turning clockwise, tighten crosswise

with M3 0,9 Nm.

Now the needle valve has to be tested for leakage and function.

- Adjustment

The needle valves are adjustable

with a slotted headscrewdriver to adjust the flow.

The NV-01 is also lockable with a

nut because the fine adjustability.

2.13.8 Pneumatic operated shut off valves NC or NO

The actuating pressure has to be supplied with a 3/2 way valve.

When the valve is not actuated the air actuation input has to vent.

Actuation pressure :

Minimal : 3 bar(g).

Maximal : 9 bar(g).

- Removing

Ensure that the system is depressurised before taking

the pneumatic shut off valve apart.

Remove the actuating pressure tubing and loosen the 4 bolts

with hexagon head counter clockwise to release the valve.

- Replacing

Replace the gasket AS-007 and AS-017, Viton, EPDM or Kalrez.

All wetted parts have to be absolutely clean, don’t use

oil or grease and avoid dust!

Replace the pneumatic shut off valve and tighten the

bolts with hexagon head by turning clockwise, tighten

crosswise with M3 0,9 Nm.

Replace the actuating pressure tubing.

Now the pneumatic shut off valve has to be tested for leakage and function.

Available Needle valves

Model number

Description

NV-01

Kvmin 1.0x10

-3

,Kvmax 6.8x10

-3

Low flow needle valve, fine

NV-02

Kvmin 5.6x10

-3

,Kvmax 5.6x10

-2

High flow needle valve, coarse

Available Pneumatic shut off valves

Model number

Description

PV-01-NC-V

Kv=0,20

Normally Closed Viton

PV-01-NC-E

Kv=0,20

Normally Closed EPDM

PV-01-NC-K

Kv=0,20

Normally Closed Kalrez

PV-01-NO-V

Kv=0,20

Normally Open Viton

PV-01-NO-E

Kv=0,20

Normally Open EPDM

PV-01-NO-K

Kv=0,20

Normally Open Kalrez

Bronkhorst

®

9.17.057

page 15

5.12.056 pneum.shut.valve PV-01-NCF-V-1

5.12.147

pneum.shut.valve PV-01-NCF-K-1

5.12.148 pneum.shut.valve PV-01-NCF-E-1

5.12.140 pneum.shut.valve PV-01-NCF-V-0

5.12.149

pneum.shut.valve PV-01-NCF-K-0

5.12.150 pneum.shut.valve PV-01-NCF-E-0

5.12.141

pneum.shut.valve PV-01-NOF-V-1

5.12.151 pneum.shut.valve PV-01-NOF-K-1

5.12.152 pneum.shut.valve PV-01-NOF-E-1

5.12.057

pneum.shut.valve PV-01-NOF-V-0

5.12.153

pneum.shut.valve PV-01-NOF-K-0

5.12.154

pneum.shut.valve PV-01-NOF-E-0

Pneum. shut off valves with feedback

NC

NO

PV-01-NCF-x-1 (10 - 30Vdc) (0Vdc)

PV-01-NCF-x-0 (0Vdc) (10 - 30Vdc)

PV-01-NOF-x-1 (10 - 30Vdc) (0Vdc)

PV-01-NOF-x-0 (0Vdc) (10 - 30Vdc)

Pneumatic shut-off valve

Signal when the valve is not operated

Signal when the valve is operated

Technical information

Service voltage 10 - 30Vdc

Max. switching current 200mA (with overload protection)

Internal power consumption <10mA

Voltage drop < 2.4V

Material PVC (Cable)

Connection 2.0 meter loose end

Bronkhorst

®

9.17.057

page 16

2.13.9 Pneumatic operated shut off 3/2 valves

The actuating pressure has to be supplied with a 3/2 way valve.

When the valve is not actuated the air actuation input has to vent.

Actuation pressure :

Minimal : 4 bar(g).

Maximal : 9 bar(g).

- Removing

Ensure that the system is depressurised before taking the

pneumatic 3/2 valve apart.

Remove the actuating pressure tubing loosen the 4 bolts with

hexagon head counter clockwise to release the valve.

- Replacing

Replace the gasket AS-007 and AS-017, Viton, EPDM

or Kalrez.

All wetted parts have to be absolutely clean, don’t use oil or

grease and avoid dust!

Replace the pneumatic 3/2 valve and tighten the bolts

with hexagon head by turning clockwise, tighten crosswise

with M3 0,9 Nm.

Replace the actuating pressure tubing.

Now the pneumatic 3/2 valve has to be tested for leakage

and function.

2.13.10 Filter modules

- Removal

Ensure that the system is depressurised before taking filter apart.

Remove the filter cup/cartrige assy by loosen the 4 bolts with

hexagon head counter clockwise to release the assy.

For disassembling the filter use a needle nose pliers place it

in the bottom part and turn the part counter clockwise for

release the filter.

- Replacement

Replace the gaskets AS-007, AS-017 and when necessary

AS-012, Viton, EPDM or Kalrez.

When necessary replace the filter cup/cartridge. These can

be ordered separately, because a dirty filter will cause

extra pressure loss over the system.

All wetted parts have to be absolutely clean, don’t use oil

or grease and avoid dust!

Replace the filter and when necessary the AS-012 gasket.

Tighten the bottom part hand tight into the cover.

Place the gaskets and tighten the bolts with hexagon head

by turning clockwise, tighten crosswise with M3 0,9 Nm.

Now the filter has to be tested for leakage and function.

Available Pneumatic operated 3/2 valves

Model number

Description

PV-32-V

NC : Kv=0,2 / NO : Kv=0.085

3/2 way Valve with Viton seals

PV-32-E

NC : Kv=0,2 / NO : Kv=0.085

3/2 way Valve with EPDM seals

PV-32-K

NC : Kv=0,2 / NO : Kv=0.085

3/2 way Valve with Kalrez seals

Available Filter modules

Model number

Description

Element Pore Size [μm]

FF-01

0,5

FF-02

2

FF-03

7

FF-04

15

Bronkhorst

®

9.17.057

page 17

FP-XX

BP-XX

2.13.11 Blind/Flow plates

- Removal

Ensure that the system is depressurised before dismounting

the blind/flow plates. Remove the Blind/Flow plates assy by

loosening the 4 bolts counter clockwise to release the assy.

- Replacement

Replace the gaskets AS-105/AS-017 for the BP-01,

AS-108/AS-115 for the BP-02, AS-017 for the FP-01 and AS-108/

AS-115 for the FP-02; Viton, EPDM or Kalrez.

All wetted parts have to be absolutely clean, don’t use

oil or grease and avoid dust! Replace the Blind/Flow plate

and tighten the bolts by turning clockwise, tighten crosswise with

M3 0,9 Nm for the Blind/Flow plate body valve/filter. For the

Blind/Flow plate controller/meter with M4 2,0 Nm. Now the

Blind/Flow plate has to be tested for leakage and function.

A Flow plate provides a flow path, in case where a module is removed

temporarily or continuously from a Base Body for a valve/filter or a

Base Body for a meter/controller.

A Blind plate blocks the flow, in case where a module is removed

temporarily or continuously from a Base Body for a valve/filter or a

Base Body for a meter/controller. In the Blind plate version for the

valve/filter there is an O-ring AS-105 which can be removed when

you want to use the plate as a Flow plate.

In the blind controller/meter version is an expander,

witch is pressed into the plate and can not be removed.

In the flow version the expander is not present.

Available Flow/Blind plates

Model number

Description

Blind plate

Flow plate

BP-01

FP-01

For valve/filter body

BP-02

FP-02

For meter/controller body

Bronkhorst

®

9.17.057

page 18

2.14 Model key

code

A

B

F

G

Z

output

0-5 Vdc

0-10 Vdc

0-20 mAdc sourcing

4-20 mAdc sourcing

specified

setpoint

0-5 Vdc

0-10 Vdc

0-20 mAdc sinking

4-20 mAdc sinking

specified

remark

--

code

V

E

K

Z

sealing material

Viton

EPDM

Kalrez

special

code

D

Z

supply

+15.. 24 Vdc

special

code

0

max. body pres.

10 bar

A S N N NAA N N N A A A N N A

code

F

t yp e

Flowmeter/controller

P Pressuremeter/controller

Surface Mount solutions

code

0

1

2

5

6

output

separate valve

flowsensor

flowsensor + valve

pressure sensor

valve + pressure sensor

7 pressure sensor + valve

inlet

0

o ut l et

0

range indication

EL-FLOW

C-sensor

FS-100C

FS-101C

FS-102C

EL-PRESS

P-sensor

PS-502C

EL-FLOW

C-sensor

FS-200CV

FS-201CV

FS-202CV

EL-PRESS

P-sensor

PS-502C

EL-PRESS

P

-sensor

PS-702C

adapter

none

--

--

--

--

actual models

Nominal range (option)

code pcb type

A

B

Digital instrument

“NC” with Analog I/O

Digital instrument

“NO” with Analog I/O

C Digital instrument “NO” with POWERLINK

D

E

I

Digital instrument “NC” with DeviceNet

Digital instrument

“NO” with DeviceNet

Digital instrument

“NC” with EtherNet/IP

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Digital instrument

“NO” with EtherNet/IP

Digital instrument

“NC” with CANopen

Digital instrument

“NO” with CANopen

Digital instrument “NC” with Modbus

Digital instrument “NO” with Modbus

Digital instrument

“NO” with POWERLINK

Digital instrument “NC” with Profibus-DP

Digital instrument

“NO” with Profibus-DP

Digital instrument

“NC” with FLOW-BUS

Digital instrument “NO” with FLOW-BUS

Digital instrument

“NC” with EtherCAT

Digital instrument

“NO” with EtherCAT

Digital instrument “NC” with PROFINET

Digital instrument

“NO” with PROFINET

Digital instrument “NC” with Modbus TCP

Digital instrument “NO” with Modbus TCP

Bronkhorst

®

9.17.057

page 19

3 Basic operation

3.1 General

A FLOW-SMS instrument is equipped with a digital electronic ‘Multibus’ pc-board. These electronics consist of a micro-

controller with peripheral circuitry for measuring, controlling and communication. The flow/pressure signal, is

measured and digitized directly at the sensor and processed by means of the internal software (firmware).

Processed values can be measured and/or operated by means of:

• Analog interface (0...5 Vdc / 0...10 Vdc / 0...20 mA / 4...20 mA)

• Digital RS232 FLOW-BUS interface (connected to COM-port by means of special cable on 38400

Baud)

• Digital RS485 Modbus interface ASCII / RTU / TCP

• Digital Profibus DP interface

• Digital DeviceNet interface

• Digital EtherCAT interface

• Digital PROFINET interface

• Digital CANopen interface

• Digital EtherNet/IP interface

• Digital POWERLINK interface

Operation via analog or digital interface can be performed at the same time. A special parameter called “control

mode” indicates to which setpoint the controller should respond.

3.2 Analog operation

At analog operation following signals are available:

• measured value (analog output)

• setpoint (analog input)

• valve voltage (controllers only)

The type of installed analog interface (0-5 V, 0-10 V, 0-20 mA or 4-20 mA) can be found in the model key of the

instrument. Refer to paragraph 2.14.

Setpoints below 2% of the full scale will be interpreted as 0% setpoint.

When operating the instrument through the analog interface it is possible to connect the instrument

simultaneously to RS232 for reading/changing parameters (e.g. controller response or other fluid

selection).

3.3 Manual interface: micro-switch and LED’s

By means of manual operation of the micro push-button switch some important actions for the instrument can be

selected/started. These options are available in both analog and digital/fieldbus operation mode.

These functions are:

- reset (instrument firmware-program reset)

- restore factory settings (in case of unaccidently changing of the settings)

The LED’s on top of the instrument can also be used for manual operation of some options. The green LED will indicate

in what mode the instrument is active. The red LED will indicate error/warning situations.

For details see “manual interface” in Operation Instructions Digital Instruments (document nr.

9.17.023, Chapter 10)

3.4 Basic RS232 FLOW-BUS operation

Digital operation adds a lot of extra features (compared to analog operation) to the instruments.

Such as:

Bronkhorst

®

9.17.057

page 20

- setpoint slope (ramp function on setpoint for smooth control)

- 8 selectable fluids (calibration settings for high accuracy)

- direct reading at readout/control module or host computer

- testing and self diagnosis

- response alarm (|setpoint-measure| too high for too long time)

- several control/setpoint modes (e.g. purge/close valve)

- master/slave modes for ratio control (FLOW-BUS only)

- identification (serialnumber, modelnumber, device type, user tag)

- adjustable minimal and maximal alarm limits

- (batch) counter

- adjustable response time for controller when opening from zero

- adjustable response time for normal control

- adjustable response time for stable control (|setpoint-measure| < 2%)

See 9.17.023 “Operation Instructions Digital Instruments” for more details about the parameters and

properties of ‘multibus’ instruments.

RS232 FLOW-BUS communication can be used for operating your instrument using the Bronkhorst® FlowDDE server

application.

Physical layer and communication protocol are detected automatically upon reception of messages.

These messages must be sent using the correct combination of physical layer and communication

protocol. After every power-up the communication detection mode is active.

Dynamic Data Exchange (DDE) provides the user a basic level of inter process communication between Windows

applications. FlowDDE is a DDE server application. Together with a client-application, either self-made or with a

SCADA-program from 3rd-parties, it is possible to create an easy way of data exchange between the flow controller

and a Windows application. For example, a cell in Microsoft Excel could be linked to the measured value of the flow

controller and when the measured value changes, it will be automatically updated in the Excel spreadsheet.

Examples of DDE client applications: FlowPlot, FlowView, MS-Office, LabView, Intouch, Wizcon.

The FlowDDE server also offers a lot of test facilities and user adjustable settings for efficient communication with the

connected flow/pressure meter or controller.

How to setup a DDE link with FlowDDE is described in the help-file of the FlowDDE application.

Programming examples are available for making applications in: Visual Basic, LabView and Excel.

FlowDDE parameter numbers:

Reading/changing parameter values via FlowDDE offers the user a different interface to the instrument.

Besides the application name: ‘FlowDDE’ there is only need of:

• topic, used for channel number: ‘C(X)’

• item, used for parameter number: ‘P(Y)’

A DDE-parameter number is a unique number in a special FlowDDE instruments/parameter database and not the

same as the parameter number from the process on an instrument.

Node-address and process number will be translated by FlowDDE to a channel number.

FlowDDE and other Bronkhorst® applications are available at the Bronkhorst® download site:

http://www.bronkhorst.com/en/downloads

A special RS232 cable (7.03.366) can be ordered separately. It consists of a T-part with 1 male and 1

female sub-D 9 connector on one instrument-side and a normal female sub-D 9 connector on the side of

the computer. By means of this cable it is possible to offer RS232 communication and still be able to

connect power-supply and analog interface through the (analog) sub-D 9 connector.

Bronkhorst

®

9.17.057

page 21

RS232 communication is only possible with a baudrate of 38.4 KBaud and can be used for either:

• Uploading new firmware by means of a special program (for trained BHT-service personnel only)

• Servicing your instrument using BHT-service programs (for trained BHT-service personnel only)

• Operating your instrument using FlowDDE, FLOWB32.DLL or RS232-ASCII protocol (end

user)

3.5 Fieldbus operation

Instructions for the range of optional fieldbus interfaces for digital Bronkhorst® instruments are separately described

in the following instruction manuals:

‘Multibus manuals’; see document numbers:

9.17.024 for FLOW-BUS

9.17.025 for PROFIBUS DP

9.17.026 for DeviceNet

9.17.027 for RS232

9.17.035 for Modbus ASCII / RTU / TCP

9.17.063 for EtherCAT

9.17.095 for PROFINET

9.17.131 for CANopen

9.17.132 for EtherNet/IP

9.17.142 for POWERLINK

Bronkhorst

®

9.17.057

page 22

4 Advanced operation

4.1 Using mass flow meters/controllers on different gases or under different

conditions

4.1.1 Stored calibration curves

FLOW-SMS instruments with digital pc-boards allow storage of max. 8 calibration curves for various gases or process

conditions. Fluidsets can digitally be selected when the instrument is hooked-up by RS232 to a computer, using

(Bronkhorst®) software tools.

4.1.2 Multi Fluid / Multi Range instruments

Instruments with activated Multi Fluid / Multi Range (MFMR) functionality are calibrated for standard ranges which

can easily be configured for other fluids and ranges. Changing fluid and range can be performed by means of the

software tool FlowTune, through the RS232 connection of an instrument. The program can convert the primal

calibration curve inside the instrument to the selected fluid and range.

In digital instruments with activated MFMR functionality the parameters capacity, density, unit type, capacity unit etc.

are dynamic parameters. For example, changing the capacity unit from ‘ml

n/min’ to ‘ln/min’ effects that the capacity

automatically changes, for instance from 2000 ml

n

/min to 2 l

n

/min. The 100% output is not affected. Changing the

capacity from 2000 ml

n

/min to 1000 ml

n

/min effects that the instruments full scale capacity (100% output) changes to

1000 ml

n/min. The instrument is reranged.

4.1.3 Conversion factor calculation using Fluidat software

Bronkhorst® gathered the physical properties of over 600 fluids in a database called FLUIDAT.

Application software, such as FLOW CALCULATIONS, enables the user to calculate accurate conversion factors, not

only at 20°C/1 atm but at any temperature/pressure combination, both for gases and for liquids.

Apply to your distributor for more details of this software.

Check FLUIDAT® on http://www.fluidat.com

FLUIDAT® is a collection of routines to calculate physical properties of gases and liquids. These routines

are made available at the FLUIDAT® on the Net website.

4.1.4 Sealing material

Before using for a different fluid, check if the sealing material of the complete module like O-rings,

plunger and packing gland of capillary are suitable for the application. The instrument is fitted with

Viton, EPDM or Kalrez seals. Which sealing material is used is shown in the last character of the model

key. It is also important to make sure that the seals of the mounting accessories (base block, adapters,

etc.) are suitable for the fluids used (see schematic diagram /dimensional drawing).

Bronkhorst

®

9.17.057

page 23

4.1.5 Maximum pressure drop

For solenoid operated control valves with small orifices the maximum allowable pressure drop for gases is according

to the general table below. Please keep in mind that the pressure rating for FLOW-SMS is 10 bar only. The Kv value of

the shut-off valves, in front of and behind the flow/pressure controllers, must be 1.5 times larger than total Kv value

of the controllers. Otherwise the pressure drop over the shut-off valve will disturb the control performance.

Diameter [mm]

K

v

Normally closed

∆

p max. [bard]

Normally opened

∆

p max. [bard]

0,05

0,07

0,10

0,14

0,20

0,30

0,37

0,50

0,70

1,00

1,30

1,50

1,70

2,00

4,33 x 10

-5

8,48 x 10

-5

1,73 x 10

-4

3,39 x 10

-4

6,93 x 10

-4

1,56 x 10

-3

2,37 x 10

-3

4,33 x 10

-3

8,48 x 10

-3

1,73 x 10

-2

2,93 x 10

-2

3,90 x 10

-2

5,00 x 10

-2

6,63 x 10

-2

40

30

30

30

30

30

30

30

24

12

8

6

5

3,6

30

20

20

20

20

20

20

20

15

8

5

n.a.

n.a.

n.a.

Bronkhorst

®

9.17.057

page 24

5 Troubleshooting and service

5.1 General

For a correct analysis of the proper operation of a flow/pressure meter or controller it is recommended to remove the

unit from the process line and check it without applying fluid supply pressure. In case the unit is dirty, this can be

ascertained immediately by loosening the compression type couplings and, if applicable the flange on the inlet side.

Energizing or de-energizing of the instrument indicates whether there is an electronic failure. After that, fluid pressure

is to be applied in order to check behaviour. If there should be suspicion of leakage in case of a gas unit, do not check

for bubbles with a leak detection liquid under the cover as this may lead to a short-circuit in the sensor or p.c.board.

5.2 LED indication

The red LED on the instrument gives error or warning information.

Red LED

Time

Indication

Off

Continuously

No error

Flash

Variable

Bus activity on the Modbus interface

On

Continuously

Critical error message

A serious error occurred in the instrument

Instrument needs service before further using

For more information check the instruction manuals for digital communication/interfaces at

http://www.bronkhorst.com/en/downloads/instruction_manuals/

Bronkhorst

®

9.17.057

page 25

5.3 Troubleshooting summary general

Symptom

Possible cause

Action

No output signal

No power supply

Check power supply and hook-up

Check cable connection and hook-up.

Check status of LED’s

(see manual 9.17.023 chapter 10)

No setpoint

For analog used instruments measure

between pin 3 and 8 of sub-D9

connector.

For digital use make sure to perform a

read setpoint after sending

Cable damaged or hooked-up wrong

Check and compare signals at both ends

of cable.

PC-board damaged due to long lasting

shortage and/or high-voltage peaks

Return to factory

No or too low inlet pressure

Increase inlet pressure

Open shut-off at inlet and outlet

Supply pressure too high, or differential

pressure across meter too high

Reduce supply pressure

Valve blocked / contaminated

Set control mode to valve fully open

and check if it opens

Sensor / capillary failure

Return to factory

Maximum output signal

Leakage of control valve

Set control mode to valve close and

check if it closes

Sensor / capillary failure

Return to factory

Output signal much lower than

setpoint signal or desired flow

Incorrect type of gas or too low inlet

pressure

Test instrument on conditions for which

it was designed

Oscillation

Supply pressure / diff. pressure too high

Reduce pressure

Pressure regulator of supply pressure is

oscillating or wrong sized

Replace pressure regulator

Controller adjustment wrong

Adjust controller with PID settings

Flow is gradually decreasing

Condensation, can occur e.g. with NH

3

Decrease supply pressure and / or heat

gas to be measured

Small flow at zero setpoint

Valve leaks due to damage or dirt

Return to factory

Increased zero reading without flow

caused by raised zero-point

Perform an auto-zero action

No digital communication

Occupied or wrong bus address

Change address with software or

rotary-switches

No or wrong bus termination

Check cabling and termination

Bronkhorst

®

9.17.057

page 26

5.4 Service

For current information on Bronkhorst® and service addresses please visit our website:

http://www.bronkhorst.com

Do you have any questions about our products? Our Sales Department will gladly assist you selecting the right product

for your application. Contact sales by e-mail:

sales@bronkhorst.com

For after-sales questions, our Customer Service Department is available with help and guidance.

To contact CSD by e-mail:

aftersal[email protected]

No matter the time zone, our experts within the Support Group are available to answer your request immediately or

ensure appropriate further action. Our experts can be reached at:

+31 589 02 18 66

Bronkhorst

®

9.17.057

page 27

6 Removal and return instructions

Instrument handlings:

• Purge gas lines

• Remove instrument from line

• Insert the instrument into a plastic bag and seal the bag

• Place the bag in a appropriate shipping container

Add documentation:

• Reason of return

• Failure symptoms

• Contaminated condition

• Declaration on Contamination form: 9.17.032

When returning material, always describe the problem and if possible the work to be done, in a covering letter.

It is absolutely required to notify the factory if toxic or dangerous fluids have been metered with the instrument!

This to enable the factory to take sufficient precautionary measures to safeguard the staff in their repair department.

Take proper care of packing, if possible use the original packing box; seal instrument in plastic, etc.

All instruments must be dispatched with a completely filled in 'declaration on contamination form'.

Instruments without this declaration will not be accepted.

Note:

If the instruments have been used with toxic or dangerous fluids the customer should pre-clean the instrument.

Important:

Clearly note, on top of the package, the customer clearance number of Bronkhorst High-Tech B.V., namely:

NL801989978B01

If applicable, otherwise contact your distributor for local arrangements.

The declaration on contamination form is available at the Bronkhorst® download site:

http://www.bronkhorst.com/en/downloads/safety_information_for_returns.pdf