ECO

200i | 250esm | 250i | 250ix | 300esm | 300i | 300ix

200is | 250is | 250isx | 300esms | 300is | 300isx | 500is | 500isx

TECHNICAL MANUAL

EN

European Certification

EN 60335-1

EN 60335-2-21

EN 60335-2-40

Directives

2006/95/CE

Revision 17

Version 1

Date 04/04/2023

Technical Manual

3

ECO

Esteemed Client,

We would like to thank you for your choice when you acquired an

equipment for sanitary water heating.

The thermodynamic solar system ECO system will surely meet all your

expectations and provide many years of comfort with maximum power

saving.

Our organization dedicates much time, energy and economic resources in

order to develop innovations that will promote power saving in our

products.

Your choice has demonstrated your good sense and concern with power

consumption, a matter that affects the environment.

We have taken on a permanent commitment to conceive innovative and

efficient products so that this rational use of energy can actively contribute

to the preservation of the environment and natural resources of the planet.

Keep this manual whose objective is to inform, alert and advise about the

use and maintenance of this equipment.

Our services are always at your disposal. Feel free to call upon us!

Technical Manual

4

ECO

Index

1. INTRO ..................................................................................................... 6

1.1 Symbols ................................................................................................................... 6

1.2 Safety Information ................................................................................................... 6

1.3 Information .............................................................................................................. 7

2 PACKAGE ................................................................................................. 9

2.1 Contents .................................................................................................................. 9

2.2. Transport ................................................................................................................10

3 SPECIFICATIONS ................................................................................... 11

3.1 Running Principle ...................................................................................................11

3.2 Techincal Features (1 panel) ..................................................................................12

3.3 Techincal Features (2 panels) ................................................................................13

3.4 Main Components ..................................................................................................14

3.4.1 General Diagram of Assembly .........................................................................14

3.4.2 Dimensions ......................................................................................................15

3.4.3 ID Plate ............................................................................................................16

3.4.4 Thermodynamic Solar Panel ............................................................................17

3.4.5 Thermodynamic Block + Storage Water Heater ...............................................18

3.4.6 Refrigerant .......................................................................................................19

3.5 Safety and Control Devices ....................................................................................19

3.5.1 Low Pressure Switch .......................................................................................19

3.5.2 Safety Thermostat ............................................................................................19

3.5.3 Temperature Probe ..........................................................................................19

3.5.4 Protection Against Corrosion (if applicable) .....................................................19

3.5.5 Dielectric Joint (enamelled boilers) ..................................................................19

3.5.6 Expansion Vessel* ...........................................................................................20

3.5.7 Safety Group ....................................................................................................20

3.5.8 Pressure Reducing Valve ................................................................................20

4 INSTALLATION ...................................................................................... 21

4.1 Attachment of the Panel .........................................................................................21

4.2 Positioning ..............................................................................................................23

4.3 Installation of Thermodynamic Block ......................................................................23

4.4 Refrigerant Connections .........................................................................................24

4.4.1 Connections to the panel .................................................................................24

4.4.2 Connection of thermodynamic block to the storage water heater ....................27

4.4.3 Connection of thermodynamic block and panel ...............................................27

4.4.4 Load of Nitrogen ..............................................................................................29

4.4.5 Vacuum ............................................................................................................29

4.4.6 Checking good running condition .....................................................................30

4.4.7 Load of complementary refrigerant (if necessary) ............................................30

4.5 Hydraulic Connections ............................................................................................30

4.6 Electrical Connections ............................................................................................31

4.6.1 Wiring diagram (1 Thermodynamic Panel) .......................................................32

4.6.1 Wiring diagram (2 Thermodynamic Panels) .....................................................33

5 FIRST USE .............................................................................................. 34

5.1 Filling the Tank .......................................................................................................34

5.2 Start Up of the System ...........................................................................................34

Technical Manual

5

ECO

6 SYSTEM OPERATION ............................................................................ 35

6.1 Control Panel ..........................................................................................................35

6.2 Keys (Functions) .....................................................................................................35

6.3 Interface Symbols ...................................................................................................36

6.4 Operating Modes ....................................................................................................36

6.4.1 ECO Operating Mode ......................................................................................37

6.4.2 AUTO Operating Mode ....................................................................................37

6.4.3 BOOST Operating Mode ..................................................................................37

6.5 Extra Modes ...........................................................................................................37

6.5.1 DISINFECT Function .......................................................................................37

6.5.2 VACATION Mode .............................................................................................38

6.5.3 PV Mode ..........................................................................................................38

7 SYSTEM MENU ...................................................................................... 39

8 ERRORS ................................................................................................. 39

9 PARAMETERS DESCRIPTION .............................................................. 40

10 PROBE CHART .................................................................................... 41

11 TROUBLESHOOTING .......................................................................... 41

12 SYSTEM MAINTENANCE .................................................................... 42

12.1 General Inspection ..............................................................................................42

12.2 Magnesium Anode (if applicable) ........................................................................43

12.3 Filter of Reduction Valve .....................................................................................43

12.4 Safety Thermostat ...............................................................................................43

12.5 Empty the Water Storage ....................................................................................44

13 DISPOSAL OF EQUIPMENT ................................................................ 44

Technical Manual

6

ECO

1. INTRO

1.1 Symbols

Every process that the supplier believes to be conducive to harmful danger and/or

material damage will be signalled with a danger sign.

To better characterize the danger, the symbol will be followed by one of these

words:

[1]

DANGER: when there is the possibility of harm to the operator and/or

people in the vicinity of the equipment

[2]

WARNING: when there is the possibility of material damage to the equipment

and/or attached materials.

All the information that the supplier believes to be an asset for better performance

and preservation of the equipment, will be signalled together with the information sign.

1.2 Safety Information

WARNING/DANGER

• The electrical installation of the equipment must comply with the national regulations for

electrical installations in effect.

• The equipment can only work if the water heater is filled with water and properly purged;

• The electrical supply is 230VAC/50Hz or 60Hz* (equipment version only designed on

specific request);

• The equipment must be connected to an electrical outlet with earth contact;

• If the power supply cable is damaged, it must be replaced by the manufacturer, by its

customer service, or by staff with similar training in order to avoid any danger.

• Children must not play with the device.

• Cleaning and maintenance must not be carried out by children without supervision.

• This appliance can be used by children aged from 8 years and above and persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge if

they have been given supervision or instruction concerning use of the appliance in a safe

way and understand the hazards involved.

• The operating principle of this equipment is directly linked to high temperatures and

pressures, so all processes that involve contact with the equipment must be prepared with

care to avoid risks of burns and material projection.

• The heating of other fluids than drinking water is not allowed.

Technical Manual

7

ECO

1.3 Information

INFORMATION

Installation

• The installation of the equipment must be carried out by staff with suitable training and

qualified for this purpose.

• The device must not be installed:

o outdoors;

o in places with corrosive environment;

o in places with a risk of temperatures below 5ºC;

o in places that present a risk of impact, shock or explosion.

• The equipment must be installed in a dry place, protected from the weather;

• Keeping the equipment packed until the place and time of installation.

• Ensure that all hydraulic connections are properly watertight before powering the

equipment electrically.

• The discharge pipe connected to the pressure limiting device must be installed in a non-

freezing environment and continuously directed downwards.

• The discharge tube of the pressure limiting device must be kept open to the atmosphere.

Maintenance

• The user is responsible for the safety and environmental compatibility of the installation

and/or maintenance.

• Maintenance/repair should only be carried out by a brand assistance service, with the

exception of general and continuous cleaning operations, which can/must be carried out

by the user himself. Repairs carried out incorrectly can create risks for the user and cause

the product to malfunction.

• The supplier recommends that at least an annual inspection of the equipment be carried

out by a qualified technician.

• Always switch off the electrical supply to the device before carrying out any maintenance

work.

• Cleaning and maintenance must not be done by children without supervision.

• Only use original replacement parts.

• The safety valve must be operated regularly to remove impurities and check that it is not

blocked.

• To drain the water from the water heater, close the supply valve and open the drain valve.

Technical Manual

8

ECO

* Pressure Reducing Valves

• Pressures admitted upstream of the pressure reducing valve:

• Maximum pressure allowed 1.2 Mpa;

• Minimum pressure allowed 0.1 MPa;

• Pressure downstream of the pressure reducing valve:

• Factory set to 0.3 MPa;

* Safety Group

The safety group allows the system to be protected in the event of anomalies in the supply of

cold water, hot water return, emptying of the water heater and high pressures. The valve is

calibrated to operate at 0.7 MPa.

Refrigerant

• Handle and recycle refrigerant gas, if necessary, in compliance with environmental laws.

It cannot be released into the environment!

• The refrigerant gas is R134a, free of CFCs, non-flammable and without harmful effects on

the ozone layer.

• Before carrying out any intervention on the components of the refrigerant circuit,

evacuate/recover the refrigerant gas in order to carry out the operations safely.

• In maintenance, it must be taken into account that fluorinated greenhouse gas HFC-134a

is used, covered by the Kyoto protocol GWP=1300.

• All gas handling must be carried out by a qualified technician.

In operation

• Water pressure:

o Minimum 0,1 MPa;

o Maximum 0,7 MPa;

• Water temperature:

o Minimum 5 °C;

o Maximum 65 °C;

Information to give to the customer

• The installer must inform the customer about the operation of the appliance, instruct him

on its handling, and the customer's rights and duties.

• Communicate to the customer the fact that the alteration or maintenance of the device

must only be carried out by specialized and accredited personnel.

(*)

Components not supplied with the equipment.

We strongly recommend its installation.

To request additional information, contact us via the email address

energie@energie.pt or via our website www.energie.pt.

Technical Manual

9

ECO

2 PACKAGE

2.1 Contents

The equipment is supplied in two packages: one package for the thermodynamic solar panel with

fixing elements, and the other with the thermo-accumulator and the attached thermodynamic group.

The packages contain:

1. Thermodynamic solar panel with fastening elements;

2. Storage water heater;

3. Thermodynamic block;

4. Installation manual, warranty, energy label and product data sheet;

5. Security group;

6. Pressure reducing valve.

4

5

3

4

2

1

Technical Manual

10

ECO

2.2. Transport

The equipment must be carried in an upright position.

The equipment must be raised and lowered with extreme care, to avoid impact that

could damage the material.

Make sure the belts and/or transportation straps do not damage the material. Always

use suitable means to transport the material (pallet lift, forklift, etc.)

The transport of the equipment must be done with an inclination never exceeding 45º;

Both the packaging containing the water heater and the thermodynamic block must be

transported in an upright position and in the correct direction.

Horizontal transport or with the equipment turned upside down can cause serious

damage to the equipment.

The equipment must always be transported in its original packaging, to the point of installation. Check,

before starting the transport of the equipment, if the path you are going to take is unobstructed, in

order to avoid collisions that could prove damage to the device.

The packaging contains the following information symbols:

Fragile, handle with extreme caution

Keep the package dry

Make sure the arrows are always up

Do not stack packages

Technical Manual

11

ECO

3 SPECIFICATIONS

3.1 Running Principle

The Thermodynamic Solar System ECO is an equipment based on the principle of compression

refrigeration - Carnot's principle - which we call the Thermodynamic Solar Systems: Solar Panel and

a Heat Pump. The solar panel, which is the main component, placed outside ensures the capture of

energy on:

a) Direct and diffuse solar radiation;

b) Outdoor air, by natural convection;

c) The effect of the wind;

d) Rain water.

The temperature difference caused by the mentioned external agents, guarantees that the R134a

(ecological refrigerant) evaporates inside the solar panel.

The absence of glass on the panel allows to increase the thermal exchanges by convection.

After passing through the panel, the R134a is aspirated by the compressor, which raises its

temperature and pressure, which in turn is transmitted to the water circuit through a condenser

external to the tank.

Before the R134a returns to the solar panel, a choke must occur, that is, through a thermostatic

expansion valve the pressure is reduced and the fluid reaches its liquid state again, thus completing

the cycle.

This facility with which we combine technology with a law of nature (change of state of a fluid),

demonstrates the veracity and potential of ECO.

Expansion

Valve

Compressor

Condenser

Technical Manual

12

ECO

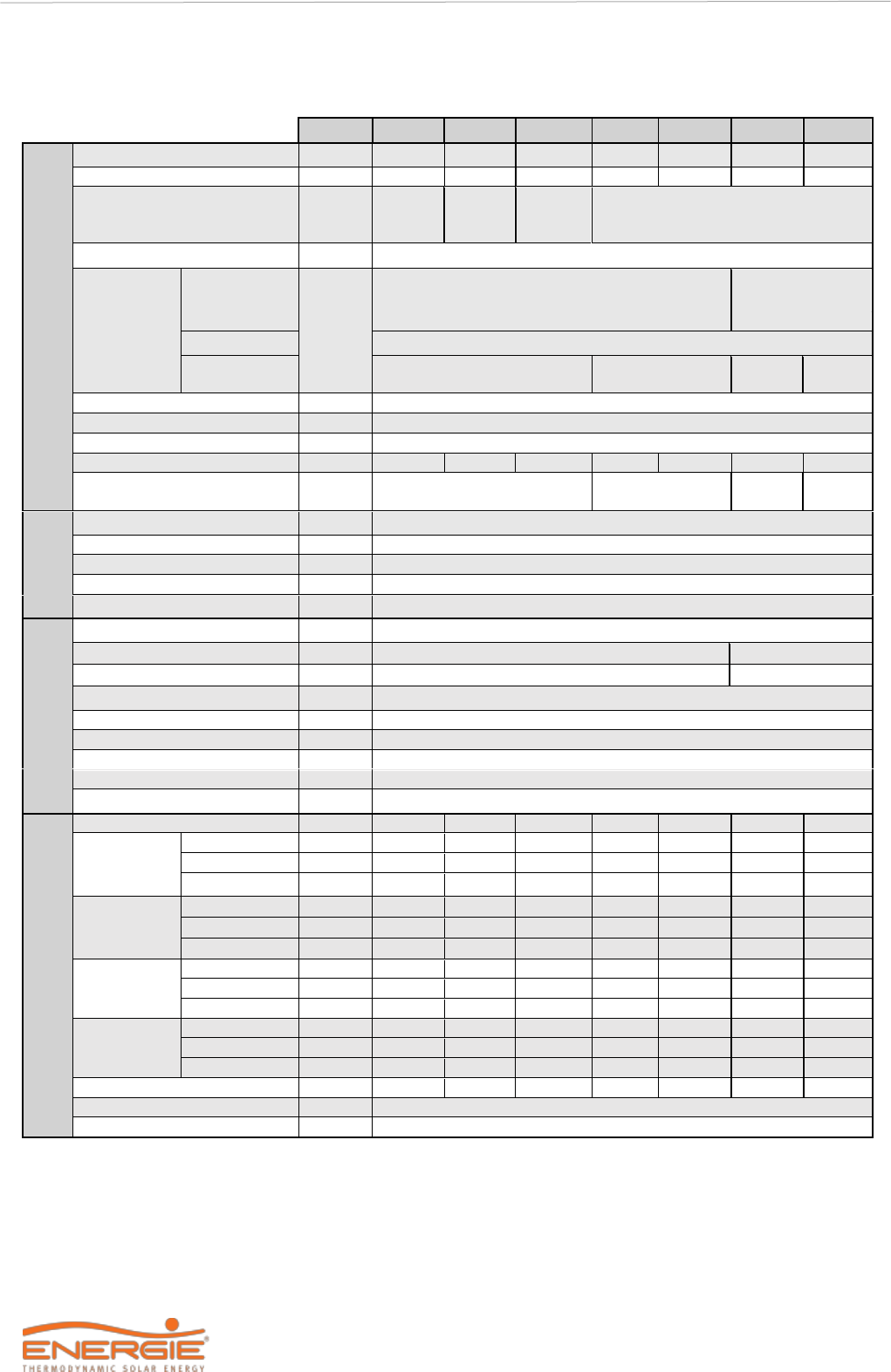

3.2 Techincal Features (1 panel)

Uni.

200i

250i / esm

300i / esm

250ix

300ix

HOT WATER CYLINDER

Dry Weight

kg

40

45 / 83

50 / 95

52

57

Capacity

L

200

250

300

245

295

Water Heater Material

-

Stainless

Steel

Stainless Steel /

Enamelled

Stainless Steel

Cathodic Protection

-

Magnesium Anode (1”1/4 F) (if applicable)

Hydraulic

Joints

Water – Inlet

and Outlet

Pol.

3/4” Male

PT Valve

1/2” Female

Recirculation

3/4” Male

Coil | Inlet e

Outlet

1” Male

Insulation

-

High density polyurethane 50mm

Maximum Pressure

bar

7

Maximum Pressure

°C

80

Heat Loss (EN 12897)

kWh/24h

0,99

1,01 / 1,20

1,17 / 1,39

1,01

1,17

Exchanger Output Power*

kW

-

a) 20 b) 12

SOLAR

PANEL

Material

-

Solar Coat Anodized Aluminium

Dimensions (L x A x E)

mm

2000 x 800 x 20

Weight

kg

8

Max Working Pressure

bar

12

Exposure Temperature

°C

-40 | 120

THERMODYNAMIC

BLOCK

Absorved Power (Med/Max)

W

390 | 650

Thermal Power (Med/Max)

W

1400 | 2380

Electrical Backup Power

W

1500

Refrigerant / Qt.**

- / g

R134a / 1300

Piping Material

-

Copper (DHP ISO1337)

Line (Liq. | Asp)

Pol.

1/4” | 3/8”

Power Supply***

V / Hz

220-240 / Single phase / 50 or 60

Fuse (Main | Electrical Heater)

A

10 | 10

Working Temperature

°C

-5 | 45

PERFORMANCE****

Tapping Porfile

-

L

XL

XL

XL

XL

Coefficient of

Performance

(COP)

Air 2ºC

-

2,8

2,9

2,9

2,9

2,9

Air 7ºC

-

3,1

3,2

3,3

3,2

3,3

Air 14ºC

-

3,6

3,8

3,7

3,8

3,7

Energy

Efficiency

ErP Class

Air 2ºC

-

A+

A

A

A

A

Air 7ºC

-

A+

A+

A+

A+

A+

Air 14ºC

-

A++

A+

A+

A+

A+

Energy

Efficiency

Air 2ºC

%

118

121

119

121

119

Air 7ºC

%

132

132

137

132

137

Air 14ºC

%

154

155

151

155

151

Annual

Energy

Consumption

Air 2ºC

KWh/ano

869

1389

1411

1389

1411

Air 7ºC

KWh/ano

774

1268

1227

1268

1227

Air 14ºC

KWh/ano

664

1078

1111

1078

1111

Mixed Water at 40°C

L

247

349

389

342

382

Default Setpoint

°C

53

Sound Power Level Indoor

dB

47

* a) Primary circuit (Tin =90 °C; Tout =80 °C); Production DHW (Tin=10 ºC; Tout=60 ºC)

b) Primary circuit (Tin =70 °C; Tout =60 °C); Production DHW (Tin=10 ºC; Tout=60 ºC)

** The amount of fluid must be checked by the installer. In some cases it is necessary to add or remove fluid in

order to ensure the correct running of the system.

*** The frequency of 60Hz is a version of the equipment produced only by specific request.

**** According to EN16147, Delegated Regulation (EU) Nº 812/2013 and Delegated Regulation (EU) Nº 844/2013,

for the three climatic zones: colder (20C), medium (70C) and warmer (140C).

Technical Manual

13

ECO

3.3 Techincal Features (2 panels)

Uni.

200is

250is

300is/esm

250isx

300isx

500is

500isx

HOT WATER CYLINDER

Dry Weight

kg

40

45

50/95

52

57

73

93

Capacity

L

200

250

300

245

295

455

443

Water Heater Material

-

Stainless

Steel

Stainless

Steel

Stainless

Steel /

Enamelled

Stainless Steel

Cathodic Protection

-

Magnesium Anode (1”1/4 F) (if applicable)

Hydraulic

Joints

Water – Inlet

and Outlet

Pol.

3/4” Male

1” Male

PT Valve

1/2” Female

1/2” Male

Recirculation

3/4” Male

Coil | Inlet e

Outlet

-

1” Male

-

1” Male

Insulation

-

High density polyurethane 50mm

Maximum Pressure

bar

7

Maximum Pressure

°C

80

Heat Loss (EN 12897)

kWh/24h

1,04

1,01

1,17/1,39

1,01

1,17

1,81

1,81

Exchanger Output Power*

kW

a) 20 b) 12

-

a)54,2

b)12

SOLAR

PANEL

Material

-

Solar Coat Anodized Aluminium

Dimensions (L x A x E)

mm

2000 x 800 x 20

Weight

kg

8

Max Working Pressure

bar

12

Exposure Temperature

°C

-40 | 120

THERMODYNAMIC

BLOCK

Absorved Power (Med/Max)

W

620 | 950

Thermal Power (Med/Max)

W

2300 | 3760

2300 | 4500

Electrical Backup Power

W

1500

2200

Refrigerant / Qt.**

- / g

R134a / 1300

Piping Material

-

Copper (DHP ISO1337)

Line (Liq. | Asp)

Pol.

3/8” | 1/2”

Power Supply***

V / Hz

220-240 / Single phase / 50 or 60

Fuse (Main | Electrical Heater)

A

10 | 10

Working Temperature

°C

-5 | 45

PERFORMANCE****

Tapping Porfile

-

L

XL

XL

XL

XL

XXL

XXL

Coefficient of

Performance

(COP)

Air 2ºC

-

2,76

2,8

2,8

2,8

2,8

2,9

2,9

Air 7ºC

-

3,09

3,2

3,1

3,2

3,1

3,3

3,3

Air 14ºC

-

3,55

3,7

3,7

3,7

3,7

3,5

3,5

Energy

Efficiency

ErP Class

Air 2ºC

-

A+

A

A

A

A

A

A

Air 7ºC

-

A+

A+

A+

A+

A+

A+

A+

Air 14ºC

-

A++

A+

A+

A+

A+

A+

A+

Energy

Efficiency

Air 2ºC

%

116

117

116

117

116

118

118

Air 7ºC

%

130

132

130

132

130

132

132

Air 14ºC

%

151

152

151

152

151

139

139

Annual

Energy

Consumption

Air 2ºC

KWh/ano

885

1438

1447

1438

1447

1823

1823

Air 7ºC

KWh/ano

786

1272

1300

1272

1300

1638

1638

Air 14ºC

KWh/ano

679

1103

1112

1103

1112

1553

1553

Mixed Water at 40°C

L

247

349

389

342

382

599

592

Default Setpoint

°C

53

Sound Power Level Indoor

dB

47

* a) Primary circuit (Tin =90 °C; Tout =80 °C); Production DHW (Tin=10 ºC; Tout=60 ºC)

b) Primary circuit (Tin =70 °C; Tout =60 °C); Production DHW (Tin=10 ºC; Tout=60 ºC)

** The amount of fluid must be checked by the installer. In some cases it is necessary to add or remove fluid in

order to ensure the correct running of the system.

*** The frequency of 60Hz is a version of the equipment produced only by specific request.

**** According to EN16147, Delegated Regulation (EU) Nº 812/2013 and Delegated Regulation (EU) Nº 844/2013, for the three

climatic zones: colder (20C), medium (70C) and warmer (140C).

Technical Manual

14

ECO

3.4 Main Components

3.4.1 General Diagram of Assembly

CAPTION

1

Shut Off Valve

7

Drain Valve

2

Pressure Reducing Valve (3 bar / 0,3 MPa)

8

Circulation Pump

3

Non-return Valve

9

Thermostatic Mixing Valve

4

Safety Group (7 bar / 0,7 MPa)

A

Cold Water Inlet

5

Drainage Siphon

B

Hot Water Outlet

6

Expansion Vessel

C

Recirculation

WARNING

It is necessary to install a safety device at the cold water inlet of the appliance.

The safety device must be in compliance with the standard EN 1487:2002,

maximum pressure 7 bar (0.7 MPa) Water must not be stopped from flowing

from the safety device to the deposit by any sort of accessory.

The safety device must be connected with piping whose diameter is not less

than the cold water inlet coupling. The discharge must be connected to a

sewage siphon or, if this is not possible, elevated to a distance of at least 20 mm

from the pavement to allow visual inspection;

To prevent high pressure from main water supply, install a pressure reduction

valve set to 3 bar (0.3 MPa).

1

2

3

1

5

6

7

1

8

3

1

9

B

C

A

4

Technical Manual

15

ECO

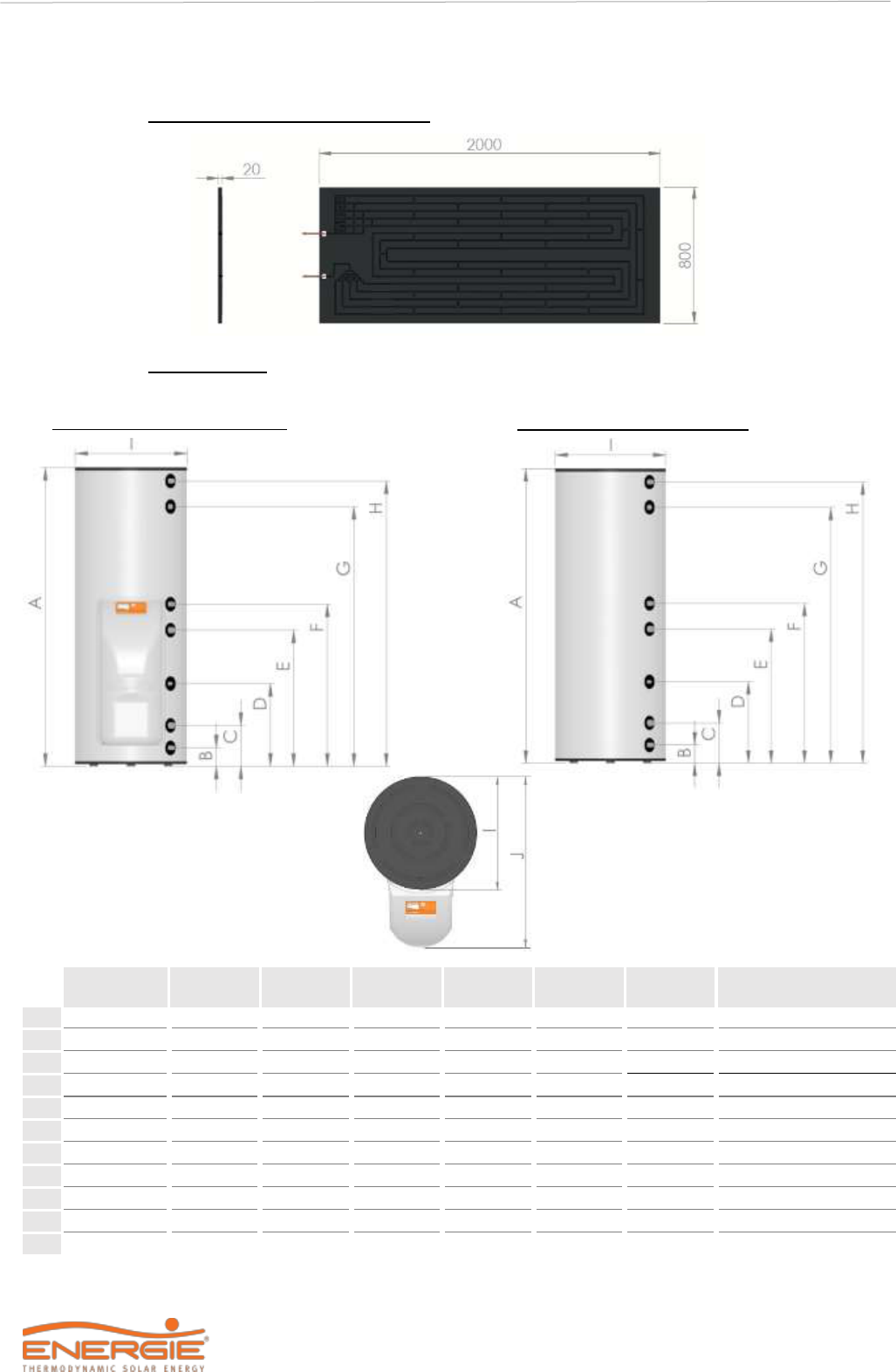

3.4.2 Dimensions

Thermodynamic Solar Panel

Interior Unit

Ø

200 i

250 esm

250 i/ix

300 esm

300 i/ix

500 i/ix

Obs.

Pol.

mm

mm

mm

mm

mm

mm

-

A

-

1240

1540

1540

1430

1400

2020

-

B

G ¾” M

131

99

131

102

107

102

Cold Water

C

G 1” M

-

-

231

-

236

635

Coil Outlet

D

-

-

-

435

-

436

-

Instrumentation

E

G 1” M

-

-

690

-

636

1525

Coil Inlet

F

G ½” F

-

840*

840

782*

855

782

Recirculation

-

G 1 ¼” M

-

1025

-

1096

-

1093

Magnesium Anode

G

G ½” F

905

1351

1205

1182

1065

1770

PT Valve

H

G ¾” M

1030

1477

1325

1325

1190

1937

Hot Water

I

-

Ø 580

Ø 580

Ø 580

Ø 650

Ø 650

Ø650

-

J

-

875

875

875

945

945

945

-

*G ¾” M

ECO 200I | ECO 250I/IX

Front hydraulic connections

ECO 250esm | 300esm/I/IX | ECO 500I/IX

Rear hydraulic connections

Technical Manual

16

ECO

3.4.3 ID Plate

Any contact with the installer or manufacturer must be accompanied by:

• Model;

• Serial number;

• Date of production.

The provision of these data will facilitate all communication and consequently a faster

and more correct response.

Technical Manual

17

ECO

3.4.4 Thermodynamic Solar Panel

The thermodynamic solar panel, responsible for the process of evaporation of the fluid, is made of

aluminium, with post-pressing anodic oxidation that gives it a black appearance.

There are two types of panels: left and right (designated by the connection side):

Left Panel Right Panel

The panels have the following pipe diameters:

•

3/8” aspiration (upper joint)

•

1/4" liquid (lower joint)

In the case of panel equipment, the refrigerant connections are of the conical threaded type (Flare

SAE):

For each panel, the elements supplied are:

1)

Thermodynamic Solar Panel;

2)

Aluminium L-shaped for attachment of Thermodynamic Solar Panel (6x ou 12x);

3)

Fixing elements.

ODS (welded on the

panel)

3/8” Flare Male SAE

ODS (welded on the

panel)

1/4” Flare Male SAE

1

2

3

Technical Manual

18

ECO

3.4.5 Thermodynamic Block + Storage Water Heater

Thermodynamic Block

We call the Thermodynamic Block to the components based on a galvanized steel structure, which

contains two of the main elements for the operation of the thermodynamic cycle: compressor and

expansion valve.

On the side of the block there are 2 and 3 way valves for connection to the panel (3/8 ’’ - Aspiration;

1/4 ’’ - Liquid).

This Thermodynamic Block is coupled to the water heater through three M8 screws and connected

to the condenser, which surrounds the water heater, through two One-Shot valves.

Storage Water Heater

The domestic hot water storage heater is vertical, resting on the ground. Thermal insulation is done

by means of high density polyurethane.

The water heater had:

• Cold water inlet;

• Hot water outlet;

• Recirculation;

• Pressure and temperature valve / instrumentation;

• Magnesium anode (joint 1 1/4" F) (if applicable);

• Possibility of integrating support coil (joint 1 "M);

• Electrical heater;

• Safety thermostat;

• Temperature probe.

Liquid Accumulator

Compressor

Electronic PCB

2-Way Valve –

Thermodynamic Panel

3-Way Valve – Thermodynamic Panel

One-Shot Valve Female

Thermostatic Expansion Valve

One-Shot Valve Male

Technical Manual

19

ECO

3.4.6 Refrigerant

R134a is an HFC refrigerant, and as such, it is not harmful to the ozone layer. They have great thermal

and chemical stability, low toxicity, are not flammable and are compatible with most materials. The

following table lists the evaporation temperature with the pressure:

T (ºC)

P (bar)

T (ºC)

P (bar)

-20

0,33

20

4,70

-15

0,64

25

5,63

-10

1,00

30

6,70

-5

1,43

35

7,83

0

1,92

40

9,10

5

2,49

45

10,54

10

3,13

50

12,11

15

3,90

55

13,83

3.5 Safety and Control Devices

3.5.1 Low Pressure Switch

In case of running outside the range of pressures recommended and defined by the supplier, the

equipment will switch off and indicate error in the electronic panel.

3.5.2 Safety Thermostat

The safety thermostat is set by the supplier to ensure that the water temperature in the storage water

heater does not exceed the standard value. If the temperature exceeds this value, the thermostat

switches off the backup electrical heater. Switching on is done manually by qualified staff, after

analysing the reasons for the switch off.

3.5.3 Temperature Probe

The purpose of the temperature probe is to measure the temperature values of water in the storage

water heater in order to control the system.

3.5.4 Protection Against Corrosion (if applicable)

Besides being resistant to corrosion (stainless steel), the storage water heater has in addition a

magnesium anode that should be checked periodically according to information by the installer.

3.5.5 Dielectric Joint (enamelled boilers)

If the boiler is made of enamelled steel, the equipment contains two dielectric bushings. These

bushings prevent electrons from exchanging between the water inlet and outlet tubes and the water

heater itself. In this way, another protection against corrosion is created, which could be verified

especially in these points.

Thus, the bushings (A) must be tightened on the inlet (B) and water outlet (B) connections of the tank,

before placing the respective tubing (C).

B

C

A

Technical Manual

20

ECO

3.5.6 Expansion Vessel*

The expansion vessel is a device whose purpose is to compensate for the increase in water volume

due to temperature rise.

3.5.7 Safety Group

The safety device allows the system to be protected against anomaly situations: cold water supply,

hot water flowing back, emptying of the storage water heater and high pressure. The valve is

calibrated to activate at 0.7 MPa).

To drain the water in the storage water heater, you should close the supply valve and open the

discharge valve.

The safety valve discharge pipe must be open into the atmosphere, because the valve may drip water

or even discharge water.

The safety valve must be opened regularly to remove impurities and check that it is not blocked. The

discharge pipe must be installed in a vertical position. The discharge pipe must be installed upright

away from a cold environment.

3.5.8 Pressure Reducing Valve

The pressure reducing valve must always be installed upstream from the safety device, and ready to

activate in situations when the pressure in the circuit exceeds 3 bar (0.3MPa). This valve comes with

a pressure gauge.

*Parts not supplied by the manufacturer. They must be installed by the installer.

WANRNING

DANGER

The placement of this device is a recommended procedure for the correct installation

of the equipment.

The installation of this device is the responsibility of the installer. The absence of

this device will void the warranty. As a general rule it is installed in the cold water

pipe.

WARNING

DANGER

The placement of this device is a mandatory procedure for the correct installation

of the equipment.

The installation of this device is the responsibility of the installer. As a general rule it

is installed in the cold water pipe.

WARNING

DANGER

The installation of the pressure reducing valve must take into account the correct

direction of the hydraulic flow.

The correct direction is represented by an arrow on the component itself.

Incorrect installation poses a danger to equipment and people.

Technical Manual

21

ECO

4 INSTALLATION

Assembly sequence:

a)

Thermodynamic solar panel fixing

b)

Placement of the cylinder + thermodynamic

block

c)

Refrigerant connections

d)

Hydraulic connections

e)

Electrical connections

f)

Nitrogen load

g)

Leak verification

h)

Vacuum

i)

Installation start-up

The unit is preloaded for a maximum connection length of up to 12

meters (horizontal) between the panel and the water heater.

Longer distances decrease the performance of your equipment.

4.1 Attachment of the Panel

The nature of the site and the inclination angle where the panels are installed are important factors to

take into account. In order to benefit the most from the sunlight exposure, the panels.

Should have a pitch between 10º and 85º relative to the horizontal plane, and preferably oriented to

the south.

The panel already comes with 6 holes for M8 in the lateral skirts. The distance between holes in the

place where the panel rests, should coincide with the holes made in the panel.

WARNING

DANGER

Attachment to at least 6 points (3 upper points and 3 lower points) is

mandatory!

The lack of at least one of these points can cause deformations in the panel and in

some cases the displacement of the panel from the installation site.

In very windy areas or climatic conditions conducive to bad weather, it is advisable to

fix the panels at more points.

Fixing the Aluminium Profiles: Fixing the aluminium profiles and the panel:

1

Aluminium profile

2

Plastic bushing

3

Self-tapping screw M6x40

4

Washer M6

5

Screw M6x20

6

Nut M6

7

Panel

Technical Manual

22

ECO

The system has 3 small profiles (side A) and 3 large profiles (side B) that must be fixed as shown in

the image, giving the panel a desirable inclination.

If the panel is to be installed in a climatic zone conducive to snowfall, the panel must

be installed with a minimum slope of 45º!

The profile must be fixed to the base (eg tile) using a plastic anchor and M6 screw provided. The

panel is fixed to the profiles using the M6 screws and the respective nuts and washers.

The panel packaging has a marking that can serve as a guide to guide the holes in the base.

This marking follows the following figure:

• A – Liquid inlet

• B – Vapour outlet (aspiration)

WARNING

DANGER

The panel must always be installed with the connections facing downwards.

750 mm

850 mm

850 mm

SIDE B

SIDE A

Technical Manual

23

ECO

4.2 Positioning

Preliminary considerations:

• House and protect the equipment in places susceptible to ice formation;

• Choose the position closest to the main points of use;

• Always insulate the pipes;

• The ambient temperature around the equipment must not exceed 40 ° C;

• The water heater should never be placed outside, also avoiding exposure to sunlight - failure

to respect this parameter can lead to the exclusion of the warranty;

• Make sure that the support surface is sufficient to accommodate the weight of the water-filled

water heater;

• Provide at least 500mm of space on the fronts that may require maintenance.

4.3 Installation of Thermodynamic Block

When assembling the thermodynamic block, must:

a) Tighten the three M8 bolts (A), in the storage water heater;

Do not fully tighten the screws, so that it is easy to insert the thermodynamic block,

giving the final tightening only after inserting the block in the water heater.

500mm

500mm

500mm

A

Technical Manual

24

ECO

b) Aim the metallic structure with the orifices to the three M8 bolts previously mentioned.

c) Set the structure, gently on the screws, adjusting the final tightening of the same;

4.4 Refrigerant Connections

Diameter of the Pipes

Nº panels

Vapour (aspiration)

Liquid (panel inlet)

-

Inches

Inches

1

3/8”

1/4"

2

1/2”

3/8”

WARNING

DANGER

• Refrigerant connections must be made by a qualified technician, with a

professional certificate of capabilities for the purpose.

• Refrigerant connections must be thermally insulated to prevent burns and to

ensure optimum system performance.

• The system has an R134a fluid preload.

4.4.1 Connections to the panel

1 Thermodynamic Panel

a) Prepare the copper pipe, removing the protective caps from the extremities.

b) Place the extremity of the pipe upside down, cut the appropriate size of pipe and sand the

rough edge.

c) Remove the females from the connections to the panel and place them on the side of the tube.

d) Flange the tube with the appropriate tool shaping a conic edge, taking care that there should

be no burrs or imperfections and the length of the walls must be uniform.

Technical Manual

25

ECO

e) Squeeze the female with your hand, taking a few turns.

It is recommended to use thread sealant, appropriate for the purpose!

The sealant must be placed between these two steps [e); f)].

If in doubt, consult the manufacturer.

f) Give the final tightening by applying a twisting pair of values as indicated in the table;

2 Thermodynamic Panels

a) Prepare the copper pipe, removing the protective caps from the extremities.

b) Place the extremity of the pipe upside down, cut the appropriate size of pipe and sand the

rough edge.

c) Then remove the covers from the panel connections and, using a sharp object, remove 5cm

of heat-shrink tubing from them;

d) Using the appropriate tool, must be made the tube expansion (3/8’’) suitable for connection

to the panel.

WARNING

Diameter of the pipe

(inches)

Applied Torque (Nm)

Wrench Nº

1/4”

14 to 16

19

3/8”

33 to 42

21

1.

2.

3.

5 cm

Technical Manual

26

ECO

e) Aim the liquid and suction tubes and before starting the welding operation, you must protect

the heat-shrink tubing (you can use a damp cloth);

f) After welding the panel connections and before installing the equipment, make sure the

apparatus has been cleaned with nitrogen.

For installations of two or more panels, it is essential that the refrigerant is distributed

evenly (Panel inlet). For this purpose, the equipment is already accompanied by a

liquid distributor.

Regarding the suction connections (Exit of the panels), the same symmetry accuracy

in the length of the tubes is not required. The same should be done by "chipping" or

with a "T" (as shown in the following image), properly isolated.

The type of solder recommended for welding the pipes is type oxyacetylene

(Oxygen/ Acetylene). Other types of gases can also be used, such as propane for

example.

WARNING

For installations of two or more panels, it is essential that the refrigerant is distributed

evenly (Panel inlet). For this purpose, the equipment is already accompanied by a

liquid distributor.

This distributor is placed between the two panels. The pipes connecting the

panels (1/4 ’’) must be exactly the same length, and their ends connect directly

to the panels.

Technical Manual

27

ECO

4.4.2 Connection of thermodynamic block to the storage water heater

After securing the thermodynamic block to the storage water heater with its bolts, we can proceed

with making the refrigeration couplings between the block and the storage water heater.

a) Remove the protection caps from the One-Shot valves on the pipes of the condenser and

thermodynamic block.

b) Tighten the valves with your hand making a few turns.

c) Tighten with a suitable wrench, applying a torque in conformity with the diameter of the pipe

employed (according to table in point 4.4.1). Insufficient torque will cause leaks of refrigerant.

Excessive torque on the coupling will damage the edge of the pipe and cause leaks.

4.4.3 Connection of thermodynamic block and panel

Some of the steps to be carried out are the repetition of the procedures carried out in

connection to the panel.

a) Cut the tube to the required size with the end facing down. Clean existing burrs;

b) Taper the tube, not forgetting to place the female on the side of the tube;

c) Squeeze the female with the hand, taking a few turns;

It is recommended to use thread sealant, appropriate for the purpose! The sealant

must be placed between these two steps [c); d)].

If in doubt, consult the manufacturer.

Technical Manual

28

ECO

d) Tighten with the appropriate wrench using the torque pair seen in the previous subchapter.

WARNING

It is important to keep the valves closed to proceed to the following points.

The water heater + thermodynamic group is filled with fluid.

The closed valves ensure that the fluid does not escape during the next steps.

All connections must be isolated!

1

3-Way-Valve

6

2-Way-Valve

2

Pressure intake

7

Conic nut

3

Valve socket

8

Liquid line (small diameter)

4

Valve needle

9

Gas line (large diameter)

5

Hexagonal tip wrench (Allen Key)

Technical Manual

29

ECO

4.4.4 Load of Nitrogen

a) After finishing the couplings, make sure there are no leaks. For this purpose, inject a load of

nitrogen with a pressure of 10 bar through the pressure inlet (3-way valve).

b) Brush every coupling in soap foam and make sure that the pressure in the pressure gauge is

constant.

4.4.5 Vacuum

a) During the whole procedure, employ, connections, vacuum pump and pressure gauges

suitable for fluid R134a.

b) Employ a vacuum pump only to remove the air and humidity inside the piping.

c) Never use the system coolant to purge the connection pipes.

d) The valves must be completely shut during the vacuum process, in order to create vacuum

only in the piping.

Closed Valves

A – 2-Way-Valves B – 3-Way-Valve

e) Create a vacuum with the vacuum pump plugged to the inlet of the 3-way pressure valve as

depicted, keeping the valves completely shut. The vacuum should be at least 30min for

installation of one panel and 45min for installation of two panels;

f) Once the vacuum procedure is over, shut the vacuum pump valves. The vacuum pressure

gauge should indicate the same reading after the pump has stopped, ensuring the installation

is in a vacuum and ready for running the coolant;

g) After concluding the vacuum procedure, you must open the two valves so that the coolant may

circulate throughout the whole system; the installation keeps the vacuum steady and is ready

for running the coolant;

h) Remove hose connected to 3-way valve.

Open Valves

A – 2-Way-Valve B – 3-Way_Valve

After vacuuming, do not remove the hoses until the system is fully pressurized by the

refrigerant.

This prevents atmospheric air (atmospheric pressure) from entering the system

(vacuum).

Technical Manual

30

ECO

4.4.6 Checking good running condition

To check whether your equipment is running correctly, start it and wait at least 30 minutes and then

check these conditions:

a) Super-heating, without solar radiation directly over the panel, should be within the range 5ºC

to 10ºC (Super-heating = Tsuction - Tevaporation);

b) The gradient between the gas temperature at the condenser inlet and the condensation

temperature must be within the range 16ºC to 20ºC.

4.4.7 Load of complementary refrigerant (if necessary)

Your unit has been pre-loaded for connections up to 12m (horizontal) between the panel and the

storage water heater. Longer distances will decrease the performance of your equipment.

Before carrying out an additional load of gas into the equipment, must prepare all the equipment and

tools necessary for the operation, such as:

• Gas bottles and their hoses

• Hexagonal-tip wrench to open the 3-way valve

• Scale with precision of 10 g

To carry out a complementary load of gas, follow these steps:

a) Place the cooling fluid tank on a scale with a 10 g precision and take note of the weight;

b) Connect the hose of the cooling fluid tank (R134a) to the inlet of the 3-way valve;

c) Switch off the compressor on the electronic panel;

d) Open carefully and only slightly the handle of the cooling fluid tank, notice the variation of the

figure indicated in the scale (as you load fluid into the circuit, the figure for the weight in the

scale will decrease);

e) When your reach the figure intended for the injection of cooling fluid into the circuit, close the

tank handle and remove the hose connected to the 3-way valve;

f) Switch on the compressor again and check how it runs.

4.5 Hydraulic Connections

WARNING/DANGER

The water you use may contain impurities and/or substances damaging to the system and even

harmful to your health. Make sure you use water with quality fitting for home consumption. The

following table indicates some parameters according to which water must be subjected to chemical

treatment.

Hardness (ºdH)

pH

Treatment

3,0 up to 20,0

6,5 up to 8,5

No

3,0 up to 20,0

<6,5 up to >8,5

Yes

<3,0 or >20,0

-

Yes

Technical Manual

31

ECO

To assemble the couplings of the hydraulic circuit you must:

a) Connect the water inlet and outlet of the equipment with a pipe and fittings that can cope with

constant temperature / pressure of 75 ºC / 7 bar. For this reason, we recommend the use of

piping with resistance to high temperature and pressure. We recommend the use of pipe type

PEX, PPR, MULTICAMADA, amongst others;

b) It is necessary to install a safety device at the cold water inlet of the appliance. The safety

device must be in compliance with the standard EN 1487:2002, maximum pressure 7 bar (0.7

MPa);

c) Besides this device, other components will be necessary to ensure the interruption of the

hydraulic load, installed according to this sequence:

• Retainer valve / gate valve

• Pressure throttle valve (in case the cold water inlet pressure exceeds 4.5 bar)

• Safety valve / discharge valve

• Expansion tank

The safety/discharge valve must be connected with piping whose diameter is not less than the cold

water inlet coupling. The discharge must be connected to a sewage siphon or, if this is not possible,

elevated to a distance of at least 20 mm from the pavement to allow visual inspection.

WARNING

We recommend the installation of a shut-off / section valve between the gate valve

and the coupling to the storage water heater for the purpose of maintenance, safety

or emergency.

The manufacturer is not responsible for damage related to not following these

recommendations / warnings.

4.6 Electrical Connections

To establish the electric connection of the equipment, check these conditions:

a) The thermodynamic equipment must be plugged to the power supply only after fill- ing the

storage water heater;

b) b) The thermodynamic equipment must be connected to a monophase voltage (230

VAC/50Hz or 60Hz* (version of the equipment produced only by specific request);

c) The connections must comply with the standards of installation in effect in the territory or

country where the thermodynamic equipment has been installed;

d) Earth wiring is obligatory.

It’s recommended that the installation includes:

• Bipolar circuit-breaker with connection cable with section equal to or exceeding 2.5 mm;

• Protection differential circuit breaker of 30 mA.

WARNING

The safety thermostat of this thermodynamic equipment must not, under any

circumstance, undergo any repair outside the installations of the manufacturer.

Not complying with this clause invalidates the warranty of the equipment.

Technical Manual

32

ECO

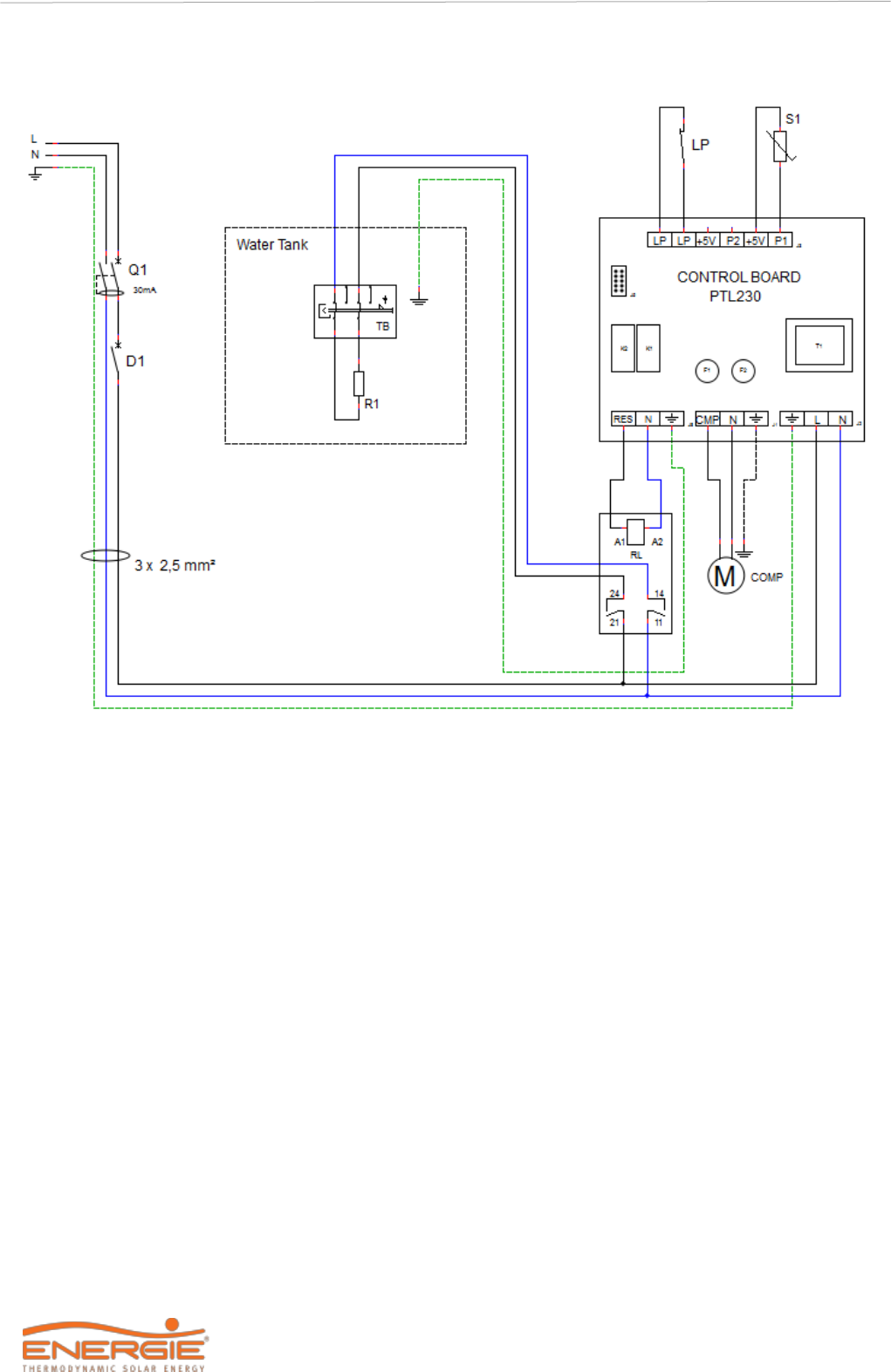

4.6.1 Wiring diagram (1 Thermodynamic Panel)

S1

Temperature probe

Comp

Compressor

LP

Low pressure switch

R1

Support electrical heater

D1

Circuit breaker

TB

Safety thermostat

Q1

Differential

Technical Manual

33

ECO

4.6.1 Wiring diagram (2 Thermodynamic Panels)

S1

Temperature probe

Comp

Compressor

LP

Low pressure switch

R1

Support electrical heater

D1

Circuit breaker

RL

Relay

Q1

Differential

TB

Safety thermostat

Technical Manual

34

ECO

5 FIRST USE

5.1 Filling the Tank

a) Open a cold water tap / isolation valve next to the safety group (this procedure is also used to

check if the drain valve is closed);

b) After obtaining flow in the hot water tap(s), shut it. Your water heater is full;

c) Check the tightening in the pipes;

d) Carry out successive discharges through the safety valve, in order to guarantee the proper

functioning of all hydraulic components of the installation.

5.2 Start Up of the System

Before starting the ECO, check whether the installation is set up according to the recommendations

and that everything is in conformity, then you may plug your equipment to the power supply. After

switching on your equipment, you should wait a few seconds until the controller begins to work.

Then you may start your equipment following these instructions:

1) Startup screen;

2) System is shut off. Press key ON/OFF to turn on the system;

3) Press the key COMP to start up the system;

4) System is running;

5) Setpoint has been reached.

Note 1: The LED on the ON / OFF button indicates the status of your device. If it is flashing, the

equipment does not have any operating order. If the light is on, your equipment is operating in one of

the available modes.

1

2

3

4

5

Technical Manual

35

ECO

6 SYSTEM OPERATION

6.1 Control Panel

The control panel of the Thermodynamic Solar system ECO is simple and intuitive. It enables the

configuration of several operating parameters according to the operating mode selected by the user.

It comprises six command keys that enable checking the running of the equipment, consult and

change parameters:

• ON / OFF / CANCEL;

• MENU;

• COMP;

• E-HEATER;

• DISINFECT;

• OK / LOCK.

6.2 Keys (Functions)

Key

Function

Description

ON/OFF

CANCEL

(ON/OFF) Switch

on/off

Switch on and off controller

(CANCEL ) Exit

ESC function to exit menu, submenu or cancel a function.

OK /

(OK) Confirmation

Confirm parameters within menus or submenus

(LOCK ) Lock/ Unlock

Lock or unlock keyboard

MENU

MENU

Access the menu.

COMP

ON/OFF Compressor

Switch on / off the Compressor.

E-HEATER

ON/OFF Electrical

Heater

Pressing the key allows you to switch on and off the

electrical heater

▲

▼

Change values

Function to run through menus and submenus (inside

Menu).

It allows you to alter value of parameter.

Browse

Menus/Submenus

DISINFECT

(DISINFECT) Anti-

legionella

Press this key and the system will automatically create a

thermal shock in the water to neutralize bacteria

(Legionella).

Technical Manual

36

ECO

6.3 Interface Symbols

Equipment in ECO operating mode

Equipment in AUTO operating mode

Equipment in BOOST operating mode

Compressor

Electrical heater

Unlocked keyboard

Locked keyboard

Timer activated after error of LP

Disinfect function is active

Holiday mode is active

Error alarm (visible on display during error)

Error memory (visible on display during 24h)

Water temperature scale in storage water heater

T

A

Electrical heater is activated when P02 < P08 and/or P07 < Temp.

S3 (Auto Mode)

T

C

Electrical heater is activated when time for continuous running of

Compressor is over T05 (Auto Mode)

LP

Electrical heater is activated by opening of LP contact (Auto/Boost

Mode)

M

Electrical heater is manually activated

6.4 Operating Modes

ECO

is programmed to work in 3 running modes,

ECO

,

AUTO

and

BOOST

, which are

summarized in this table:

The equipment is configured by default to work in the “

ECO

” operating mode. If the user

finds it necessary to change the operating mode, he must carry out the following procedures:

Unlock the keyboard and press the

Menu

key; on the ▲ ▼ keys, scroll through the menu

and select

F03

, access the submenu and select the desired operating mode

Modo

Simbologia

Funcionamento

ECO

Normal running as Thermodynamic System

AUTO

Optimized management of running of Thermodynamic System and/or

Electrical Heater (support)

BOOST

Running of Thermodynamic System + Electrical Heater (support)

Technical Manual

37

ECO

6.4.1 ECO Operating Mode

In ECO operating mode, the equipment runs only as a Heat Pump to heat the water in the storage

water heater. Thus, we could generate a greater efficiency, and savings for the user. Every time the

user feels it necessary, may switch on the support electrical heater, using this mode, manually

pressing the key (E-HEATER). In these circumstances the equipment will automatically change

operating mode to BOOST and indicates the reason of its activation (over the electrical heater). If you

switch off the electrical heater manually, the equipment will begin to run again in ECO mode.

6.4.2 AUTO Operating Mode

In AUTO operating mode, the equipment will run as a Thermodynamic System and/or electrical

heater, and the operation of the electrical heater is managed in an optimized way for the purpose of

keeping up the efficiency of the equipment.

The electrical heater will start every time:

• The user activates it manually (key E-Heater).

• The contact LP opens (low external temperature, lack of fluid, leak in the circuit, etc.).

• The time for running the compressor exceeds parameter T05*

• The water temperature is below P08*.

*Parameter is adjustable (ON / OFF)

6.4.3 BOOST Operating Mode

In BOOST operating mode, the equipment runs as a Heat Pump + Electrical Heater, and the

running of the electrical heater is simultaneous with the Heat Pump. This mode enables the user to

obtain hot water in less time.

The user can change the operating mode when he wishes, he need only press

simultaneously the keys MENU + OK/LOCK for 3 seconds and select the mode that

suits his needs with the cursor.

6.5 Extra Modes

6.5.1 DISINFECT Function

The

ECO

electronic controller is enabled with the

Disinfect

function, which consists of a

water heating cycle at 65 ° C, for an appropriate period of time to prevent the formation of

germs in the tank.

The

Disinfect

function can be configured automatically or manually. In automatic mode the

user has the possibility to configure the execution of the function daily, weekly or monthly,

being inactive the user has to activate it manually in the

Disinfect

button. At the end of the

function, the system returns to the operating mode initially adopted.

The Disinfect function is activated:

•

When pressed the disinfect button for 3 seconds;

•

On the penultimate day of the holiday period (during the holiday period the value

adopted in the disinfect parameter must be null);

•

Depending on the configuration adopted in the disinfect parameter;

•

The disinfect function is disactivated when the

CANCEL

or

COMP

key is pressed.

Technical Manual

38

ECO

6.5.2 VACATION Mode

To activate the

vacation

function, you need to access the menu and set the number of days

on holiday that you wish, and your equipment will automatically enter

Standby

mode until

the last day of holidays. On the last day, the equipment will begin the

Disinfect

function to

eliminate any formation of germs that appeared in the storage water heater during the time

you were absent. After the holidays and once the program Disinfect is over, the equipment

will resume the mode selected (

ECO

,

AUTO

or

BOOST

).

Note:

If you set your equipment to enter Vacation mode and turn it off with the key ON/OFF,

the function becomes inactive. When you return from your holidays you must remember to

switch on your equipment and cancel the days of holidays introduced (Value=0). If you do

not carry out this operation, your equipment will not restart until the days of holidays selected

have expired.

6.5.3 PV Mode

The PV function offers the possibility to raise the water temperature when an alternative electrical

energy source is available (solar photovoltaic, wind or other), increasing the efficiency of the heat

pump and making the alternative electrical energy source more profitable.

To do this, simply connect a cable from the inverter to the equipment control board. The cable

connection on the control board must be made at the 5V / P2 terminals. Note that this is a dry contact

(no voltage), applying a voltage to this contact can cause irreversible damage to the controller.

When the K1 contact closes, the PV function is activated and all active heat sources (Heat Pump +

Electrical Heater) are adjusted to new operating parameters. The compressor will assume the

parameters P01PV / H01PV and the electrical heaters the parameters P02PV / H02PV.

Note: when contact K1 opens, the equipment assumes the operating mode previously adopted.

Contact K1 can also be used to take advantage of bi-hourly rates. To do this, simply connect a timer

to the 5V / P2 terminals instead of the inverter.

OFF

ON

t

Set Point

Par (P01)

Par (P01PV)

Par (P02)

Par (P02PV)

Compressor

Resistência

K1

Electrical heater

Technical Manual

39

ECO

7 SYSTEM MENU

Every time it becomes necessary to change or set new parameters on the equipment, the user must

access the Menu.

To access the menu, the key MENU must be pressed for 3 seconds.

After access use the keys COMP

▲

and E-HEATER

▼

,to navigate the menus and submenus.

In order to confirm values/parameters press the key OK/LOCK. Press the key CANCEL to exit the

menu.

8 ERRORS

Symbols

Description

Problem

/

Checking

Er01 – S1

Anomaly

detected in probe

1

Damaged probe - Measure the probe's internal resistance

which at a temperature of 25ºC is approximately 10 KΩ.

Probe disconnected from the controller - Check that the

connector is securely connected to the electronic board

and/or that the connection terminals are tight.

Er02 – S2

Anomaly

detected

in probe 2,

when applicable

E03 – TA

Anomaly

detected in water

temperature

Water temperature in storage water heater is too hot –

Check that there is no anomaly in the electronic board, such

as a damaged relay.

Temperature probes in short-circuit – Measure internal

resistance of probe, it should be approximately 10 KΩ at the

temperature of 25ºC, check that the connector is well

attached to the electronic plate and the connection

terminals are in good condition.

Error “Lo”

Temperature

probe is

damaged or in

short-circuit

Check the connections of the temperature probe.

Replace with new probe.

LP

Protection

system is

activated

Check low pressure switch – Check if the connector is well

attached to the electronic plate and that the connection

terminals are secure, or that the pressure gauge is running.

Lack of refrigerant fluid in the circuit – Load of refrigerant

incomplete or leak. Low external temperature.

LINK

ERROR

Communication

failure

Connection cable between display and command panel

– Check the cable is in good condition or that the plugs are

correctly inserted (display and command panel).

Technical Manual

40

ECO

9 PARAMETERS DESCRIPTION

Values

Code

Type

Parameters

/

Description

Min

Max

Default

F01

Language

Português; English; Français; Deutsche; Español;

Italiano;

***

***

English

F02

Clock

Date and Time

***

***

***

F03

Mode

Eco

Boost

Auto

***

***

Eco

F04

Holidays

Number of days

0

366

0

F05

Disinfect

0- Disinfect function inactive

1- Disinfect function active once a week (weekly)

2- Disinfect function active once a month (monthly)

***

***

INACTIVE

F06

Parameters

P01 - Setpoint Compressor

1

10

55

52

0

C

H01 - Gradient P01

2

10

3

0

C

P02 - Setpoint Electrical Heater

1

65

52

0

C

H02 - Gradient P02

2

20

3

0

C

P05 – Safety Temperature

70

80

70

0

C

P06

- Setpoint Disinfect

60

69

65

0

C

P08 – Temp. min water to activate electrical heater

1

40

Value = 16 °C

Parameter=ON

T01 – Delay time to compressor starts running

1

20

2 min

T05 – Maximum time compressor running (AUTO)

6h

15h

Value = 12 horas

Parameter=ON

T07 – Delay time to compressor starts running after LP

error

2

20

10 min

P01PV - Setpoint Compressor (K1 contact closed)

10

55

55

0

C

H01PV –Gradient P01PV

2

10

3

0

C

P02PV - Setpoint Electrical Heater (K1 contact closed)

1

65

60

0

C

H02PV - Gradient P02PV

2

20

5

0

C

F07

Info

Information of the values configured in the parameter list.

F08

Levels of access

Installer

***

***

Password: 0022

F09

Test Outputs

CO – Contact N.O.

Compressor output active

OFF

ON

OFF

RE – Contact N.O.

Electrical heater output active

F10

Errors

Elist - Errors list

***

***

***

Ereset - Delete errors list

Manufacturer access

F11

Restore values

Restore all the parameters to factory values

***

***

***

F12

System

Probes’ configuration

Manufacturer access

Technical Manual

41

ECO

10 PROBE CHART

11 TROUBLESHOOTING

Problem

Possible causes

How to proceed

Failure in

electronic board

Power supply failure

Check the power supply

Check the corresponding circuit breaker

Cable damaged or disconnected

Check the integrity of the electronic board’s

electric circuit

Low water

temperature

Equipment is switched OFF

Press the key ON/OFF.

Absence of electrical current or damaged

wiring.

Check the connection of equipment to the

socket.

Check that the corresponding circuit-breaker is

connected.

Check the integrity of the cables. Check that the

electrical cable is disconnected from the

electronic.

Check electric protection (Fuse RES).

Component malfunction.

Check the presence of error on electronic board

and consult the table of errors.

Use of large amount of hot water

Set “BOOST” mode and wait for water heating.

Low temperature programmed in the

Setpoint.

Adjust the temperature of the Setpoint.

ECO mode is selected and outside

temperature quite low

Set “AUTO” mode to start automatic

management of system.

Set “BOOST” mode for a fast water heating.

Electrical heater is off.

Make sure electrical heater has power supply.

Compressor is off.

Switch on compressor with key “COMP”.

Return of hot water into the cold water

circuit (safety device incorrectly installed

or damaged)

Shut off the cold water supply valve to switch off

the safety device. Open a hot water tap. Wait 10

minutes and if you get hot water, replace the

faulty plumbing and/or proceed with the correct

positioning of the safety device.

Clean the filter of the safety device.

Technical Manual

42

ECO

Problem

Possible causes

How to proceed

Water is too hot

and/or there is

steam

Problem with the probe.

Problem with the thermostat.

Check error display on electronic board.

Check correct running of thermostat.

Slow running of

thermodynamic

solar system and

excessive

running of

electrical heater

(AUTO)

Outside temperature is very low

The running of the equipment depends

on weather conditions.

Inlet water temperature is very low

The running of the equipment depends

on the inlet water temperature.

Low value for Setpoint.

Increase the value of Set-point.

Installation has low electric voltage.

Make sure the installation is supplied

with the indicated value for voltage.

Problems with the thermodynamic solar

system.

Check the error display in the electronic board.

Low hot water

flow rate

Loss or clogging of hydraulic circuit.

Check the condition of the hydraulic circuit.

Loss of water

through safety

device

Absence or incorrect dimensioning

of expansion tank (if leak is not continuous)

Installation and/or correct dimensioning of

expansion tank.

Pressure in circuit is high (if the leak is

continuous)

Check the throttle valve (if there is one

installed).

Installation of a throttle valve (if it lacks one).

Consumption

abnormally high

and constant

electrical

Loss or obstruction in cooling circuit

Check that the piping is not damaged.

Employ equipment suitable for checking leaks

in the circuit.

Dire environmental conditions

Electrical heater

does not work

Thermostat failure

Check the condition of the thermostat.

Defective electrical heater

Check the condition of the electrical heater.

Bad odour

Absence of siphon or siphon without water

Install and make sure the siphon has water.

Others

Contact customer service.

12 SYSTEM MAINTENANCE

12.1 General Inspection

During the equipment’s useful life, the owner should carry out a general inspection of the

equipment, according to the place where the equipment is set up:

•

External cleaning of equipment and surrounding areas with a wet cloth;

•

Visual inspection of the whole equipment, with the purpose of detecting possible leaks

and damaged devices.

DANGER

Before carrying out any maintenance operations on the equipment, make

sure that it is not electrically powered!

Any intervention must be carried out by a specialized technician.

Technical Manual

43

ECO

12.2 Magnesium Anode (if applicable)

This equipment has a magnesium anode that together with the building material of the tank

will provide an

effective protection against corrosion.

The internal shielding of the tank will ensure an effective protection against corrosion

contributing to a water quality within the parameters considered normal. However, the

characteristics of the water change according to the installation. (See Chapter 4.5 and

warranty)

In your living area, the quality of the water can be aggressive to your equipment. So together

with the equipment there is a magnesium anode that wears over time, thus protecting your

equipment.

The wear of the anode always depends on the characteristics of the water you use. Thus,

checking the condition of the anode is very important, particularly in the first years of the

installation. To check the condition of your anode, follow these steps:

•

Unplug the appliance from the power supply

•

Shut off water supply

•

Remove pressure (for example, open a hot water tap)

•

Unscrew the anode with a suitable tool

•

Check the level of wear of the anode and replace it, if necessary

•

If the diameter of the anode is less than 15mm, it will need to be replaced

The extension of the deposit's anti-corrosion guarantee is conditioned to the sending

of documentary proof of the annual replacement of the magnesium anode.

12.3 Filter of Reduction Valve

To periodically clean the filter of the reduction valve, you should:

a) Shut off the water supply;

b) Turn anti-clockwise until you remove tension from the spring;

c) Remove the handle;

d) Remove filter and clean.

12.4 Safety Thermostat

The safety thermostat is disarmed whenever there is an anomaly in the system, so,

whenever you want to rearm it, find out what happened for it to have acted.

If you do not find out what happened and it is still disarmed, contact after-sales service to

have your case resolved.

If everything is in order and you want to reset the thermostat, proceed as follows:

Remove the bonnet by loosening the four screws present;

• Unscrew the cover (1);

• Press button (2) to reset the thermostat;

•

Retighten the cover (1) and replace the bonnet, tightening the four screws again.

1

2

Technical Manual

44

ECO

12.5 Empty the Water Storage

After ensuring the water temperature is at a safe level that will avoid burns, follow this

procedure:

•

Unplug the system from the power supply;

•

Shut off the water supply valve and open a hot water tap;

•

Open the system discharge valve.

13 DISPOSAL OF EQUIPMENT