DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

1 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

NEHRU COLLEGE OF ENGINEERING AND RESEARCH CENTRE

(Accredited by NAAC, Approved by AICTE New Delhi, Affiliated to APJKTU)

Pampady, Thiruvilwamala(PO), Thrissur(DT), Kerala 680 588

DEPARTMENT OF MECHATRONICS

LAB MANUAL

ME230- FLUID MECHANICS AND MACHINES LABORATORY

VISION

To mould our youngsters into millennium leaders not only in technological and scientific fields

but also to nurture and strengthen the innate goodness and humane nature in them to face the

future challenges in technological breakthroughs and information explosions and deliver the

bounties of the frontiers of knowledge for the benefit of mankind in general and down-trodden

and under-privileged in particular as envisaged by our great former prime minister Pandit

Jawaharlal Nehru.

MISSION

To built a strong centre of excellence in learning and research in engineering and frontiers in

technology, To felicitate students to learn and imbibe discipline, culture and spirituality besides

encouraging them to assimilate the latest technological knowhow to render a helping hand to the

underprivileged, thereby acquiring happiness and imparting the same to others without any

reservation what’s ever to turn the college into a magnificent and mighty launching pad to turn

out technological giants, dedicated research scientists and intellectual leaders of the society who

could prepare the country for a quantum jump in all fields of science and technology.

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

2 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

ABOUT DEPARTMENT

Established in: 2013

Course offered: B.Tech Mechatronics Engineering

Approved by AICTE New Delhi and Accredited by NAAC

Affiliated to the University of Dr. A P J Abdul Kalam Technological University.

DEPARTMENT VISION

To develop professionally ethical and socially responsible Mechatronics engineers to serve the

humanity through quality professional education.

DEPARTMENT MISSION

1) The department is committed to impart the right blend of knowledge and quality

education to create professionally ethical and socially responsible graduates.

2) The department is committed to impart the awareness to meet the current challenges in

technology.

3) Establish state-of-the-art laboratories to promote practical knowledge of mechatronics to

meet the needs of the society

PROGRAMME EDUCATIONAL OBJECTIVES

I. Graduates shall have the ability to work in multidisciplinary environment with good

professional and commitment.

II. Graduates shall have the ability to solve the complex engineering problems by applying

electrical, mechanical, electronics and computer knowledge and engage in life long learning in

their profession.

III. Graduates shall have the ability to lead and contribute in a team entrusted with

professional social and ethical responsibilities.

IV. Graduates shall have ability to acquire scientific and engineering fundamentals necessary

for higher studies and research.

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

3 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

PROGRAM OUTCOMES (PO‟S)

Engineering Graduates will be able to:

PO 1. Engineering knowledge: Apply the knowledge of mathematics, science, engineering

fundamentals, and an engineering specialization to the solution of complex engineering

problems.

PO 2. Problem analysis: Identify, formulate, review research literature, and analyze complex

engineering problems reaching substantiated conclusions using first principles of mathematics,

natural sciences, and engineering sciences.

PO 3. Design/development of solutions: Design solutions for complex engineering problems

and design system components or processes that meet the specified needs with appropriate

consideration for the public health and safety, and the cultural, societal, and environmental

considerations.

PO 4. Conduct investigations of complex problems: Use research-based knowledge and

research methods including design of experiments, analysis and interpretation of data, and

synthesis of the information to provide valid conclusions.

PO 5. Modern tool usage: Create, select, and apply appropriate techniques, resources, and

modern engineering and IT tools including prediction and modeling to complex engineering

activities with an understanding of the limitations.

PO 6. The engineer and society: Apply reasoning informed by the contextual knowledge to

assess societal, health, safety, legal and cultural issues and the consequent responsibilities

relevant to the professional engineering practice.

PO 7. Environment and sustainability: Understand the impact of the professional engineering

solutions in societal and environmental contexts, and demonstrate the knowledge of, and need

for sustainable development.

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

4 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

PO 8. Ethics: Apply ethical principles and commit to professional ethics and responsibilities and

norms of the engineering practice.

PO 9. Individual and team work: Function effectively as an individual, and as a member or

leader in diverse teams, and in multidisciplinary settings.

PO 10. Communication: Communicate effectively on complex engineering activities with the

engineering community and with society at large, such as, being able to comprehend and write

effective reports and design documentation, make effective presentations, and give and receive

clear instructions.

PO 11. Project management and finance: Demonstrate knowledge and understanding of the

engineering and management principles and apply these to one’s own work, as a member and

leader in a team, to manage projects and in multidisciplinary environments.

PO 12. Life-long learning: Recognize the need for, and have the preparation and ability to

engage in independent and life-long learning in the broadest context of technological change.

PROGRAM SPECIFIC OUTCOMES (PSO‟S)

PSO 1: Design and develop Mechatronics systems to solve the complex engineering problem by

integrating electronics, mechanical and control systems.

PSO 2: Apply the engineering knowledge to conduct investigations of complex engineering

problem related to instrumentation, control, automation, robotics and provide solutions.

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

5 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

COURSE OUTCOME

CO VS PO‟S AND PSO‟S MAPPING

CO

PO

1

PO

2

PO

3

PO

4

PO

5

PO

6

PO

7

PO

8

PO

9

PO1

0

PO1

1

PO12

PS01

PSO2

CO 1

3

3

1

1

3

2

3

2

2

2

CO 2

3

3

1

3

2

2

2

3

3

2

CO 3

3

3

1

3

2

3

3

3

2

2

CO 4

3

2

2

2

3

2

1

3

2

1

CO 5

3

2

2

2

2

1

1

2

2

2

CO 6

3

3

2

2

3

2

2

2

2

2

2

CO 7

3

2

2

2

3

2

2

2

2

2

Note: H-Highly correlated=3, M-Medium correlated=2, L-Less correlated=1

CO 1

To acquire the basic knowledge and experimentally determination of

discharge through the flow measuring equipment – orificemeter,

venturimeter

CO 2

To acquire the knowledge about factors affecting the efficiency of a

centrifugal pump, reciprocating pump ,gear oil pump

CO 3

Experimentally discuss about the factors related to the efficiency of

Pelton wheel, Francis turbine, Kaplan turbine

CO 4

To know about the factors affecting the flow through pipes

CO 5

To acquire the basic knowledge about notches

CO 6

Experimentally finding the major losses in a pipe flow

CO 7

Discuss physical basis of Bernouli’s equation

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

6 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

PREPARATION FOR THE LABORATORY SESSION

GENERAL INSTRUCTIONS TO STUDENTS

1. Read carefully and understand the description of the experiment in the lab

manual. You may go to the lab at an earlier date to look at the experimental facility

and understand it better. Consult the appropriate references to be completely familiar with the

concepts and hardware.

2. Make sure that your observation for previous week experiment is evaluated by

the faculty member and your have transferred all the contents to your record before

entering to the lab/workshop.

3. At the beginning of t he class, if t he facult y or the instructor finds that

a student is not adequately prepared, they will be marked as absent and not be

allowed to perform the experiment.

4. Bring necessary material needed (writing materials, graphs, calculators, etc.) to

perform the required preliminary analysis. It is a good idea to do sample calculations and as

much of the analysis as possible during the session. Faculty help will be available. Errors in

the procedure may thus be easily detected and rectified.

5. Please actively participate in class and don’t hesitate to ask questions. Please

utilize the teaching assistants fully. To encourage you to be prepared and to read

the lab manual before coming to the laboratory, unannounced questions may be asked at any

time during the lab.

6. Carelessness in personal conduct or in handling equipment may result in serious

injury to the individual or the equipment. Do not run near moving

machinery/equipment’s. Always be on the alert for strange sounds. Guard against

entangling clothes in moving parts of machinery.

7. Students must fo llow the proper dress code inside the laboratory. To

protect clothing from dirt, wear a lab coat. Long hair should be tied back. Shoes covering

the whole foot will have to be worn.

8. In performing the experiments, please proceed carefully to minimize

any water spills, especially on the electric circuits and wire.

9. Maintain silence, order and discipline inside the lab. Do n’t use cell

phones inside the laboratory.

10. Any injury no matter how small must be reported to the instructor immediately.

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

7 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

11. Check with faculty members one week before the experiment to make sure that

you have the handout for that experiment and all the apparatus.

AFTER THE LABORATORY SESSION

1. C l e a n up y o u r w o r k a r e a .

2. Check with the technician before yo u leave.

3. Make sure you understand what kind of report is to be prepared and due

submission of record is next lab class.

4. Do sample calculat ions and some preliminary work to verify that

the experiment was successful

MAKE-UPS AND LATE WORK

Students must participate in all laboratory exercises as scheduled. They must obtain

permissionf r o m t he f a c u lt y m e m b e r f o r a b s e n c e , whi c h w o u l d be g r a n

t e d o n l y u n d e r j u s t i f ia b l e circumstances. In such an event, a student must

make arrangements for a make-up laboratory, which will be scheduled when the time is

available after completing one cycle. Late submission will be awarded less mark for record

and internals and zero in worst cases.

LABORATORY POLICIES

1. Food, beverages & mobile phones are not allowed in the laboratory at any time.

2. Do not sit or place anything on instrument benches.

3. Organizing laboratory experiments requires the help of laboratory technicians

and staff. Be punctual.

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

8 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

SYLLABUS

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

9 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

EXP

NO

EXPERIMENT NAME

PAGE NO

1

DETERMINATION OF COEFFICIENT OF DISCHARGE OF

GIVEN ORIFICE METER

10

2

DETERMINATION OF CO EFFICIENT OF DISCHARGE OF

GIVEN VENTURIMETER

16

3

PERFORMANCE TEST AND DRAWING

THECHARACTERISTICS CURVES OF CENTRIFUGAL PUMP

22

4

CONDUCTING EXPERIMENTS AND DRAWING THE

CHARACTERISTICS CURVES OF RECIPROCATING PUMP

28

5

CONDUCTING EXPERIMENTS AND DRAWING THE

CHARACTERISTICS CURVES OF GEAR OIL PUMP

33

6

CONDUCTING EXPERIMENTS AND DRAWING THE

CHARACTERISTICS CURVES OF PELTON WHEEL TEST RIG

39

7

CONDUCTING EXPERIMENTS AND DRAWING THE

CHARACTERISTICS CURVES OF FRANCIS TURBINE TEST RIG

44

8

CONDUCTING EXPERIMENTS AND DRAWING THE

CHARACTERISTICS CURVES OF KAPLAN TURBINE TEST RIG

48

9

DETERMINATION OF FRICTION FACTOR OF

GIVEN SET OF PIPES

53

10

DETERMINE THE COEFFICIENT OF DISCHARGE OF NOTCH

58

11

DETERMINE THE FRICTION FACTOR FOR THE PIPES (MAJOR

LOSSES)

62

12

VERIFY THE BERNOULLI’S THEOREM

66

13

DETERMINATION OF COEFFICIENT OF DISCHARGE OF A

V - NOTCH

70

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

10 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

1. DETERMINATION OF COEFFICIENT OF DISCHARGE OF GIVEN

ORIFICE METER

AIM

To determine the theoretical discharge through the passage using orifice meter and to find the co-

efficient of discharge of the given orifice meter.

DESCRIPTION

Orifice meter has two sections. First one is of area a1, and second one of area a2, it does not have

throat like venturi meter but a small holes on a plate fixed along the diameter of pipe. The

mercury level should not fluctuate because it would come out of manometer.

APPARATUS REQUIRED

1. Orifice meter

2. Differential U tube

3. Collecting tank

4. Stop watch

5. Scale

PROCEDURE

1. Measure the length and breadth of the collecting tank.

L = m & B = m.

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

11 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

2. Open the respective valve in the pipeline and close all the other valves. Adjust the flow

suitably

3. Note the left limb reading (h1) and the right limb reading (h2)m of the manometer.

Close the drain valve of the collecting tank.

Find the time taken for 10cm (t) rise of water level in the collecting tank.

4. Repeat the experiment for the different flow rates and through different flow meters

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

12 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

OBSERVATION AND RESULT TABULATION:

Diameter Of The Pipe Inlet (d

1

) = m Length Of The Collecting Tank = m

Orifice Diameter (d

2

) = m Breadth Of The Collecting Tank = m

Cd = Q

act

/

Q

the

average =

Q

the

m

3

/sec

Q

act

m

3

/sec

Time

taken for

10cm rise

of water

in the

tank (T)

sec

Diff of head

h

(m)

MANOMETER READINGS

h

1 -

h

2

(m)

h

2

(cm)

h

1

(cm)

S.NO

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

13 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

14 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

15 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

16 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

2. DETERMINATION OF CO EFFICIENT OF DISCHARGE OF GIVEN

VENTURIMETER

AIM

To determine the theoretical discharge through the passage using orifice meter and to find the

co-efficient of discharge of the given venturi meter.

DESCRIPTION

Venturimeter has two sections. One divergent area and the other throat area. The former is

represented as a

1

and the later is a

2

water or any other liquid flows through the venturimeter and

it passes to the throat area the value of discharge is same at a

1

and a

2.

APPARATUS REQUIRED

1.

Venturi meter

2.

Differential U tube

3.

Collecting tank

4.

Stop watch

5.

Scale

PROCEDURE

1. Measure the length and breadth of the collecting tank.

L = m.

B = m.

2. Open the respective valve in the pipeline and close all the other valves. Adjust the flow

suitably

3.

Note the left limb reading (h

1

) m and the right limb reading (h

2

) m of the manometer.

4. Close the drain valve of the collecting tank.

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

17 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

5. Find the time taken for 10cm (t) rise of water level in the collecting tank

6. Repeat the experiment for the different flow rates and through different flow meters

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

18 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

OBSERVATION AND RESULT TABULATION:

Diameter Of The Pipe Inlet (d

1

) = m Length Of The Collecting Tank = m

Orifice Diameter (d

2

) = m Breadth Of The Collecting Tank = m

Cd = Q

act

/

Q

the

average =

Q

the

m

3

/sec

Q

act

m

3

/sec

Time

taken for

10cm rise

of water

in the

tank (T)

sec

Diff of head

h

(m)

MANOMETER READINGS

h

1 -

h

2

(m)

h

2

(cm)

h

1

(cm)

S.NO

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

19 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

20 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

21 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

22 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

3. PERFORMANCE TEST AND DRAWING THE

CHARACTERISTICS CURVES OF CENTRIFUGAL PUMP

AIM

To study the performance characteristics of a centrifugal pump and to determine the

characteristic with maximum efficiency.

DESCRIPTION

PRIMING

The operation of filling water in the suction pipe casing and a portion delivery pipe

for the removal of air before starting is called priming. After priming the impeller is rotated by a

prime mover. The rotating vane gives a centrifugal head to the pump. When the pump attains a

constant speed, the delivery valve is gradually opened. The water flows in a radially outward

direction. Then, it leaves the vanes at the outer circumference with a high velocity and pressure.

Now kinetic energy is gradually converted in to pressure energy. The high-pressure water is

through the delivery pipe to the required height

APPARATUS REQUIRED

1. Centrifugal pump setup

2. Meter scale

3. Stop watch

PROCEDURE

1. Prime the pump close the delivery valve and switch on the unit

2. Open the delivery valve and maintain the required delivery head

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

23 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

3. Note down the reading and note the corresponding suction head reading

4. Close the drain valve and note down the time taken for 10 cm rise of water level in

collecting tank

5. Measure the area of collecting tank

6. For different delivery tubes, repeat the experiment

7. For every set reading note down the time taken for 10 revolutions of energy meter disc

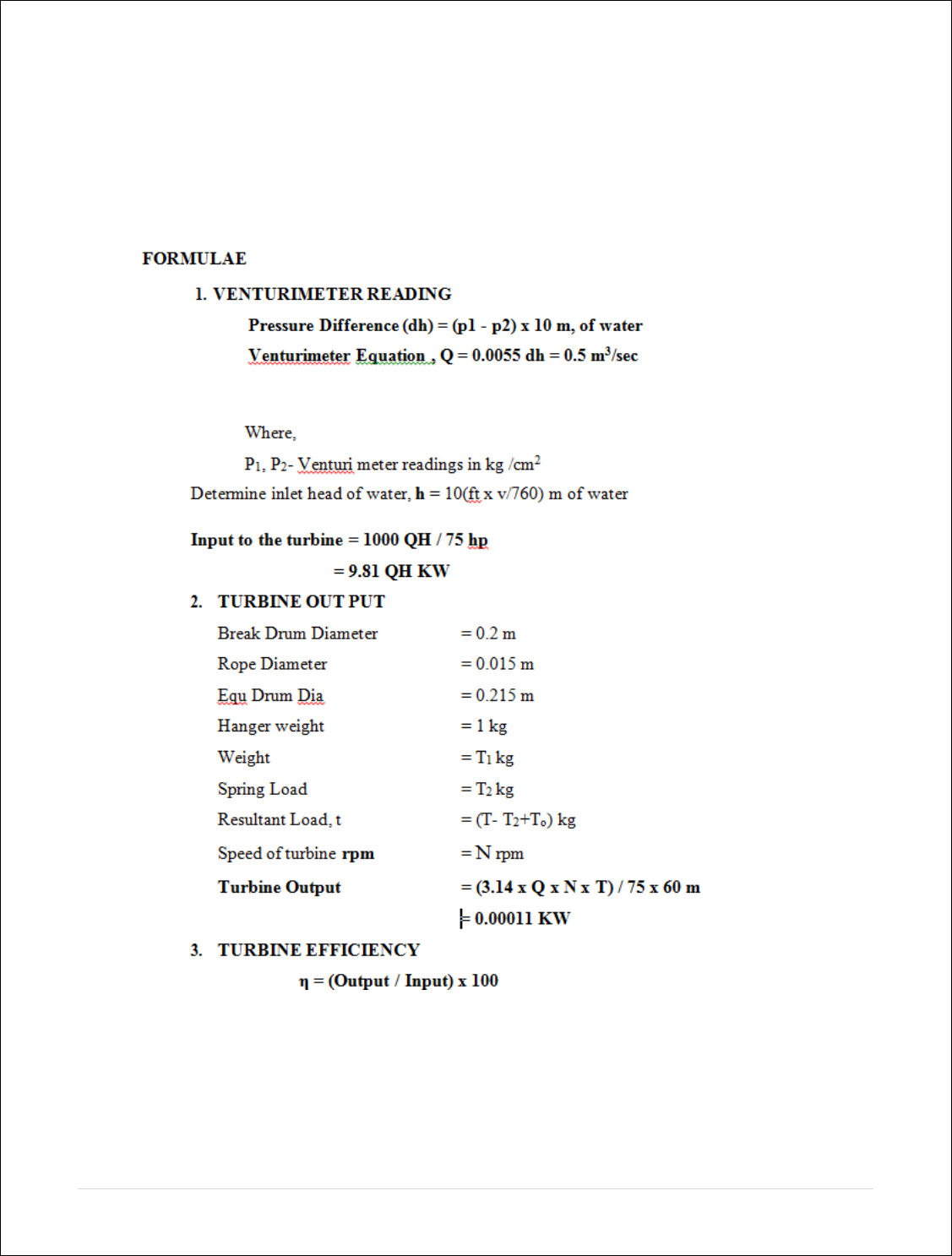

FORMULAE

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

24 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

25 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

OBSERVATION AND RESULT TABULATION:

LENGTH OF THE COLLECTING TANK (m) =

BREADTH OF THE COLLECTING TANK (m) =

Efficiency

%

Output

Power

Kw

Input Power

Kw

Discharge Q

m

3

/sec

average =

Time

taken for

10rev of

energy

meter (t)

sec

Time

taken for

10cm rise

of water

in the

tank (T)

sec

Total

Head „H‟

m of

Water

Vaccum

Gauge

Readings

(V)

Kg/cm

2

Pressure

Gauge

Readings

(P)

Kg/cm

2

S.NO

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

26 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

27 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

28 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

4.CONDUCTING EXPERIMENTS AND DRAWING THE

CHARACTERISTICS CURVES OF RECIPROCATING PUMP

AIM

To study the performance characteristics of a reciprocating pump and to determine the

characteristic with maximum efficiency.

APPARATUS REQUIRED

1. Reciprocating pump

2. Meter scale

3. Stop watch

PROCEDURE

1. Close the delivery valve and switch on the unit

2. Open the delivery valve and maintain the required delivery head

3. Note down the reading and note the corresponding suction head reading

4. Close the drain valve and note down the time taken for 10 cm rise of water level in

collecting tank

5. Measure the area of collecting tank

6. For different delivery tubes, repeat the experiment

7. For every set reading note down the time taken for 10 revolutions of energy meter disc

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

29 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

OBSERVATION AND RESULT TABULATION:

Length Of The Collecting Tank = m Stroke Length ( L ) = m

Breadth Of The Collecting Tank = m Speed Of The Crank (rpm) =

Efficiency

%

Output

Power

Kw

Input

Power

Kw

% slip

Theoretical

discharge

Qthe

m3 /sec

Actual

Discharge

Qact

m3 /sec

average =

Time taken

for 10rev of

energy

meter

(t) sec

Time taken

for 10cm

rise of

water in

the tank

(T) sec

Total Head

„H‟ m of

Water

Vaccum

Gauge

Reading

s (V)

Kg/cm2

Pressure

Gauge

Readings

(P)

Kg/cm2

S.NO

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

30 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

31 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

32 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

33 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

5. CONDUCTING EXPERIMENTS AND DRAWING THE

CHARACTERISTICS CURVES OF GEAR OIL PUMP

AIM

To draw the characteristics curves of gear oil pump and also to determine efficiency of given

gear oil pump.

DESCRIPTION

The gear oil pump consists of two identical intermeshing spur wheels working with a fine

clearance inside the casing. The wheels are so designed that they form a fluid tight joint at the

point of contact. One of the wheels is keyed to driving shaft and the other revolves as the driven

wheel.

The pump is first filled with the oil before it starts. As the gear rotates, the oil is trapped in

between their teeth and is flown to the discharge end round the casing. The rotating gears build-

up sufficient pressure to force the oil in to the delivery pipe.

APPARATUS REQUIRED

1. Gear oil pump setup

2. Meter scale

3. Stop watch

PROCEDURE

1. The gear oil pump is stated.

2. The delivery gauge reading is adjusted for the required value.

3. The corresponding suction gauge reading is noted.

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

34 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

4. The time taken for ‘N’ revolutions in the energy meter is noted with the help of a

stopwatch.

5. The time taken for ‘h’ rise in oil level is also noted down after closing the gate valve.

6. With the help of the meter scale the distance between the suction and delivery gauge is

noted.

7. For calculating the area of the collecting tank its dimensions are noted down.

8. The experiment is repeated for different delivery gauge readings.

9. Finally the readings are tabulated

.

.

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

35 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

OBSERVATION AND RESULT TABULATION:

LENGTH OF THE COLLECTING TANK = m

BREADTH OF THE COLLECTING TANK = m

Efficiency

%

Output

Power

Kw

Input

Power

Kw

Discharge Q

m

3

/sec

average =

Time

taken for

10rev of

energy

meter (t)

sec

Time

taken for

10cm rise

of water

in the

tank (T)

sec

Total

Head „H‟

m of

Water

Vaccum

Gauge

Readings

(V)

Kg/cm

2

Pressure

Gauge

Readings

(P)

Kg/cm

2

S.NO

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

36 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

37 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

38 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

RESULT

Thus the performance characteristic of gear oil pump was studied and maximum efficiency was

found to be. ………%

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

39 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

6. CONDUCTING EXPERIMENTS AND DRAWING THE

CHARACTERISTICS CURVES OF PELTON WHEEL TEST RIG

AIM

To conduct load test on Pelton wheel turbine and to study the characteristics of Pelton

wheel turbine

DESCRIPTION

Pelton wheel turbine is an impulse turbine, which is used to act on high loads and for generating

electricity. All the available heads are classified in to velocity energy by means of spear and

nozzle arrangement. Position of the jet strikes the knife-edge of the buckets with least relative

resistances and shocks. While passing along the buckets the velocity of the water is reduced and

hence an impulse force is supplied to the cups which in turn are moved and hence shaft is rotated

APPARATUS REQUIRED

1. Venturimeter

2. Stopwatch

3. Tachometer

4. Dead weight

PROCEDURE

1. The Pelton wheel turbine is started.

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

40 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

2. All the weight in the hanger is removed.

3. The pressure gauge reading is noted down and it is to be maintained constant for different

loads.

4. The Venturi meter readings are noted down.

5. The spring balance reading and speed of the turbine are also noted down.

6. A 5Kg load is put on the hanger, similarly all the corresponding readings are noted down.

7. The experiment is repeated for different loads and the readings are tabulated.

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

41 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

OBSERVATION AND RESULT TABULATION:

Diameter Of The Pipe Inlet (D

1

) = m Orifice Diameter (D

2

= m

Length Of The Collecting Tank = m Breadth Of The Collecting Tank = m

OP

KW

IP

KW

TURBINE

OUTPUT

NET

WEIGHT

T

average =

WEIGHT

OF G

BALAN

C

E T

2

WEIGHT

OF

HANGER

T

1

SPEED

N

Flow

ratio

Q

VENTURIMETER

READINGS

P

3

(cm)

p

2

(cm)

p

1

(cm)

Total

head

INLET

PRESSU

RE

SL

. N O

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

42 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

43 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

RESULT

Thus the performance characteristic of the Pelton Wheel Turbine is done and the maximum

efficiency of the turbine is ………. %

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

44 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

7.CONDUCTING EXPERIMENTS AND DRAWING THE

CHARACTERISTICS CURVES OF FRANCIS TURBINE TEST RIG

AIM

To conduct load test on Francis turbine and to study the characteristics of Francis turbine

APPARATUS REQUIRED

1. Stop watch

2. Tachometer

DESCRIPTION

Modern Francis turbine in an inward mixed flow reaction turbine it is a medium head turbine.

Hence it required medium quantity of water. The water under pressure from the penstock enters

the squirrel casing. The casing completely surrounds the series of fixed vanes. The guides’ vanes

direct the water on to the runner. The water enters the runner of the turbine in the dial direction at

outlet and leaves in the axial direction at the inlet of the runner. Thus it is a mixed flow turbine.

APPARATUS REQUIRED

1. Stop watch

2. Tachometer

PROCEDURE

1. The Francis turbine is started

2. All the weights in the hanger are removed

3. The pressure gauge reading is noted down and this is to be maintained constant for

different loads

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

45 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

4. Pressure gauge reading is ascended down

5. The Venturi meter reading and speed of turbine are noted down

6. The experiment is repeated for different loads and the readings are tabulated.

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

46 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

OBSERVATION AND RESULT TABULATION:

OP KW

IP KW

TURBINE

OUTPUT

NET

WEIG

HT

T

average =

WEIGHT

OF G

BALANC

E T

2

WEIGHT

OF

HANGER

T

1

SPEED

N

Flow

ratio

Q

VENTURIMETER

READINGS

P

3

(cm)

p

2

(cm)

p

1

(cm)

Total

head

INLET

PRESSURE

S.NO

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

47 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

RESULT

Thus the performance characteristic of the Francis wheel turbine is done and the maximum

efficiency of the turbine is …………. %

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

48 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

8. CONDUCTING EXPERIMENTS AND DRAWING THE

CHARACTERISTICS CURVES OF KAPLAN TURBINE TEST RIG

AIM

To study the characteristics of a Kaplan turbine

DESCRIPTION

Kaplan turbine is an axial flow reaction turbine used in dams and reservoirs of low height to

convert hydraulic energy into mechanical and electrical energy. They are best suited for low

heads say from 10m to 5 m. the specific speed ranges from 200 to 1000

The flow through the pipelines into the turbine is measured with the office meter fitted in the

pipeline. A mercury manometer is used to measure the pressure difference across the orifice

meter. The net pressure difference across the turbine output torque is measured with a pressure

gauge and vacuum gauge. The turbine output torque is determined with the rope brake drum. A

tachometer is used to measure the rpm.

APPARATUS REQUIRED

1. Venturi meter

2. Stopwatch

3. Tachometer

4. Dead weight

EXPERIMENTAL PROCEDURE

1. Keep the runner vane at require opening

2. Keep the guide vanes at required opening

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

49 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

3. Prime the pump if necessary

4. Close the main sluice valve and they start the pump.

5. Open the sluice valve for the required discharge when the pump motor switches from star

to delta mode.

6. Load the turbine by adding weights in the weight hanger. Open the brake drum cooling

water gate valve for cooling the brake drum.

7. Measure the turbine rpm with tachometer

8. Note the pressure gauge and vacuum gauge readings

9. Note the orifice meter pressure readings. Repeat the experiments for other loads

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

50 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

51 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

OBSERVATION AND RESULT TABULATION:

OP KW

IP KW

TURBINE

OUTPUT

NET

WEIGHT

T

average =

WEIGHT

OF G

BALANC

E T

2

WEIGHT

OF

HANGER

T

1

SPEED

N

Flow

ratio

Q

VENTURIMETER

READINGS

P

3

(cm)

p

2

(cm)

p

1

(cm)

Total

head

INLET

PRESSU

RE

SL

NO

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

52 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

RESULT

Thus the performance characteristic of the Kaplan turbine is done and the maximum efficiency

of the turbine is …………. %

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

53 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

9.DETERMINATION OF FRICTION FACTOR OF

GIVEN SET OF PIPES

AIM

To find the friction ‘f’ for the given pipe.

DESCRIPTION

When liquid flows through a pipeline it is subjected to frictional resistance. The frictional

resistance depends upon the roughness of the pipe. More the roughness of the pipe will be more

the frictional resistance. The loss of head between selected lengths of the pipe is observed.

APPARATUS REQUIRED

1. A pipe provided with inlet and outlet and pressure tapping

2. Differential u-tube manometer

3. Collecting tank with piezometer

4. Stopwatch

5. Scale

PROCEDURE

1. The diameter of the pipe is measured and the internal dimensions of the collecting tank

and the length of the pipe line is measured.

2. Keeping the outlet valve closed and the inlet valve opened

3. The outlet valve is slightly opened and the manometer head on the limbs h1 and h2 are

noted

4. The above procedure is repeated by gradually increasing the flow rate and then the

corresponding readings are noted

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

54 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

OBSERVATION AND RESULT TABULATION:

Diameter Of The Pipe(d

1

) = m Length Of The Collecting Tank = m

Length Of The Pipe( l ) = m Breadth Of The Collecting Tank = m

Friction

factor (f)

average =

Q

act

m

3

/sec

Velocity

V

m

3

/sec

Time

taken for

10cm rise

of water

in the

tank (T)

sec

Diff of head

h

(m)

MANOMETER READINGS

h

1 -

h

2

(m)

h

2

(cm)

h

1

(cm)

S.NO

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

55 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

56 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

57 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

RESULT:

1. The frictional factor ‘f ‘ for given pipe =------------- x 10-2 (no unit)

2. The friction factor for given pipe by graphical method = ------------- x 10-2 (no

unit)

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

58 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

10. DETERMINE THE COEFFICIENT OF DISCHARGE OF NOTCH

AIM

To determine the coefficient of discharge of ‘ V ‘Notch

DESCRIPTION

Notches are overflow structure where length of crest along the flow of water is accurately

shaped to calculate discharge. The bottom edge, over which the liquid flows, is known as sill or

crest of the notch and the sheet of liquid flowing over a notch (or a weir) is known as nappe or

vein. A notch is, usually made of a metallic plate and is used to measure the discharge of liquids.

APPARATUS REQUIRED

1. Supply Tank,

2. Collecting Tank

3. Pointer, Scale

4. V Notch

PROCEDURE

1. The notch under test is positioned at the end of tank with vertical sharp edge on the

upstream side.

2. Open the inlet valve and fill water until the crest of notch.

3. Note down the height of crest level by pointer gauge.

4. Change the inlet supply and note the height of this level in the tank.

5. Note the volume of water collected in collecting tank for a particular time and find out

the discharge.

6. Height and discharge readings for different flow rate are noted

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

59 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

60 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

FORMULAE

Where:-

Q = Discharge

H =Height above crest level

θ= Angle of notch

B = Width of notch

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

61 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

RESULT:

The value of Cd for V-notch……

The value of Cd for rectangular notch……

The value of Cd for trapezoidal notch ……

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

62 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

11. DETERMINE THE FRICTION FACTOR FOR THE PIPES (MAJOR LOSSES)

AIM

To determine the friction factor for the pipes.(Major Losses)

DESCRIPTION

Friction factor in pipes or Major losses:- A pipe is a closed conduit through which fluid flows

under the pressure. When in the pipe, fluid flows, some of potential energy is lost to overcome

hydraulic resistance which is classified as:-

1. The viscous friction effect associated with fluid flow.

2. The local resistance which result from flow disturbances caused by sudden expansion and

contraction in pipe

Obstruction in the form of valves, elbows and other pipe fittings. curves and bend in the pipe.

APPARATUS REQUIRED

1. Supply Tank,

2. Collecting Tank

3. Pipes having different diameter

4. Manometers

PROCEDURE

1. Note down the relevant dimensions as diameter and length of pipe between the pressure

tapping, area of collecting tank etc.

2. Pressure tapping of a pipe is kept open while for other pipe is closed.

3. The flow rate was adjusted to its maximum value. By maintaining suitable amount of

steady flow in the pipe.

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

63 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

4. The discharge flowing in the circuit is recorded together with the water level in the left

and right limbs of manometer tube.

5. The flow rate is reduced in stages by means of flow control valve and the discharge &

reading of manometer are recorded.

6. This procedure is repeated by closing the pressure tapping of this pipe, together with

other pipes and for opening of another pipe.

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

64 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

Observation:-

Diameter of pipe D =

Length of pipe between pressure tapping L =

Area of collecting tank =

Sr.

No.

Manometer Reading

Discharge measurement

F

=

π

2

g

D

5

/

8

L

Q

2

ℎ

f

Left

limb

H

1

Right

limb

H

2

Difference of

head in term of

water

h

f

=

13.6(H

2

-H

1

)

Initi

al

cm.

Final

cm.

Time

sec

Discharge

Q

(cm

3

/sec)

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

65 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

RESULT:

Friction factors:

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

66 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

12. VERIFY THE BERNOULLI‟S THEOREM

AIM

To verify the Bernoulli’s theorem

DESCRIPTION

Bernoulli’s theorem states that when there is a continues connection between the particle of

flowing mass liquid, the total energy of any sector of flow will remain same provided there is no

reduction or addition at any point

APPARATUS REQUIRED

1. Supply tank of water

2. Tapered inclined pipe fitted with no. of piezometer tubes point

3. Measuring tank,

4. Scale

5. Stop watch

PROCEDURE

1. Open the inlet valve slowly and allow the water to flow from the supply tank.

2. Now adjust the flow to get a constant head in the supply tank to make flow in and out

flow equal.

3. Under this condition the pressure head will become constant in the piezometer tubes.

4. Note down the quantity of water collected in the measuring tank for a given interval of

time.

5. Compute the area of cross-section under the piezometer tube.

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

67 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

6. Compute the area of cross-section under the tube.

7. Change the inlet and outlet supply and note the reading.

8. Take at least three readings as described in the above steps.

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

68 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

1

2

3

4

5

6

7

8

9

10

Reading of

piezometric tubes

Area of cross

section under the foot

of each point

Velocity of water

under foot of each

point

V

2

/2g

p/ρ

V

2

/2g + p/ρ

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

69 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

RESULT:

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

70 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

13. DETERMINATION OF COEFFICIENT OF DISCHARGE OF A

V - NOTCH

AIM

To calibrate a V –notch

DESCRIPTION

NOTCH:

A Notch is regarded as an orifice with water level below its upper edge. Notch is made of a

metallic plate and its use is to measure the discharge of liquids. These are used for measuring the

flow of water from a vessel or tank with no pressure flow. Since the top edge of the notch above

the liquid level serves no purpose therefore a notch may have only bottom edge and sides.

SILL “OR” CREST OF A NOTCH:The bottom edge over which liquid flows is known as Sill

or Crest of the notch.

RECTANGULAR NOTCH:The notch which is Rectangular in shape is called as the

rectangular notch. Coefficient of discharge (Cd): It is the ratio between the actual discharge and

the theoretical discharge. Mathematically

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

71 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

PROCEDURE

1. Fix the plate having rectangular notch in the water passage of Hydraulic bench.

2. Turn the hydraulic bench on; water will accumulate in the channel.

3. When the water level reaches the Crest or sill of notch stop the inflow and note the

reading, and design it as H1.

4. Restart the bench and note the volume and time of water that accumulates in the

volumetric tank of bench, from this find the discharge, and also note the height of water

at this point.

5. Find H = H2 – H1 This will give you the head over the notch.

6. Find the width of the notch.

7. Take different readings by changing the discharge head over the notch, using the above

procedure.

8. Plot a graph between Log10H and Log10Q and find K from graph equation.

Find Cd from the following formula. Cd = 2 / 3 x k / √2g x b

Observation :

Triangular or V -notch.

Apex angle of Notch , =

Crest Level of trapezoidal notch H1=

Area of collecting tank, a=

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

72 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

DEPARTMENT OF MECHATRONICS, NCERC PAMPADY.

73 | P a g e

FLUID MECHANICS AND MACHINES LAB WORKBOOK

RESULT