Full Terms & Conditions of access and use can be found at

http://www.tandfonline.com/action/journalInformation?journalCode=bfsn20

Download by: [Texas A&M University Libraries] Date: 12 January 2016, At: 11:28

Critical Reviews in Food Science and Nutrition

ISSN: 1040-8398 (Print) 1549-7852 (Online) Journal homepage: http://www.tandfonline.com/loi/bfsn20

Fish Protein Hydrolysates: Production,

Biochemical, and Functional Properties

Hordur G. Kristinsson & Barbara A. Rasco

To cite this article: Hordur G. Kristinsson & Barbara A. Rasco (2000) Fish Protein Hydrolysates:

Production, Biochemical, and Functional Properties, Critical Reviews in Food Science and

Nutrition, 40:1, 43-81, DOI: 10.1080/10408690091189266

To link to this article: http://dx.doi.org/10.1080/10408690091189266

Published online: 03 Jun 2010.

Submit your article to this journal

Article views: 1946

View related articles

Citing articles: 262 View citing articles

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

43

Critical Reviews in Food Science and Nutrition, 40(1):43–81 (2000)

I. INTRODUCTION

At this time there are huge amounts of pro-

tein-rich byproduct materials from seafood pro-

cessing plants discarded without any attempt of

recovery. At the same time many processors are

no longer allowed to discard their offal directly

into the ocean, resulting in a very high cost of

refining the material before it is discarded. To

meet the need of the seafood processing industry,

an alternative to discarding these byproducts

should be developed. Recovery and alteration of

the fish muscle proteins present in the byproduct

material and using these as functional ingredients

in food systems is a very exciting and promising

alternative. However, for the industry to develop

processes for byproduct recovery and utilization

it has to be more economically feasible than dis-

carding the byproducts.

Every year over 91 million tons of fish are

harvested, of which 29.5% is transformed into

fishmeal.

1,2

Possibly more than 50% of the re-

maining fish tissue is considered to be processing

waste and not used as food.

3

With a dramatically

increasing world population and a world catch of

fish presently on the verge of exceeding the esti-

mated sustainable limits of the suggested 100

million tons/year, there is obviously an increased

need to utilize our sea resources with more intel-

ligence and foresight. By applying enzyme tech-

nology for protein recovery in fish processing, it

may be possible to produce a broad spectrum of

Fish Protein Hydrolysates:

Production, Biochemical, and Functional

Properties

Hordur G. Kristinsson* and Barbara A. Rasco**

Institute for Food Science and Technology, The School of Fisheries, University of Washington, Seattle,

Washington 98105

Referee: Dr. George M. Pigott, President, Sea Resources Engineering Inc., 4525 105 Avenue, N.W., Kirkland, WA, 98033

* Corresponding author: Present address: Department of Food Science, University of Massachusetts at Amherst, Marine Foods

Laboratory, Marine Station, Gloucester, Massachusetts 01930; Fax: (978) 281-2618; E-mail: [email protected]

** Present address: Department of Food Science and Human Nutrition, Washington State University, P.O. Box 646376, Pullman,

Washington 99164

ABSTRACT: Considerable amounts of fish processing byproducts are discarded each year. By developing

enzyme technologies for protein recovery and modification, production of a broad spectrum of food ingredients

and industrial products may be possible. Hydrolyzed vegetable and milk proteins are widely used food ingredients.

There are few hydrolyzed fish protein foods with the exception of East Asian condiments and sauces. This review

describes various manufacturing techniques for fish protein hydrolysates using acid, base, endogenous enzymes,

and added bacterial or digestive proteases. The chemical and biochemical characteristics of hydrolyzed fish

proteins are discussed. In addition, functional properties of fish protein hydrolysates are described, including

solubility, water-holding capacity, emulsification, and foam-forming ability. Possible applications of fish protein

hydrolysates in food systems are provided, and comparison with other food protein hydrolysates where pertinent.

KEY WORDS: fish protein hydrolysates, fish protein, functional properties, chemical hydrolysis of fish protein,

enzymatic hydrolysis of fish protein, protein functionality, fish byproducts.

Downloaded by [Texas A&M University Libraries] at 11:28 12 January 2016

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

44

food ingredients or industrial products for a wide

range of applications. This would utilize both

fishery byproducts or secondary raw materials

and, in addition, underutilized species that would

otherwise be discarded.

Enzymatic modification of proteins using

selected proteolytic enzyme preparations to cleave

specific peptide bonds is widely used in the food

industry.

4

Hydrolysis of food proteins has a long

history, mainly for vegetable and milk proteins;

these proteins are widely used in the food indus-

try. Most work on the hydrolysis of fish proteins

was conducted in the 1960s. Some fish protein

hydrolysate (FPH) preparations at that time were

quite successful.

5

During the 1960s, research was

directed to the production of cheap nutritious pro-

tein sources for rapidly growing developing coun-

tries, or toward animal feed production, primarily

through production of fish protein concentrates

(FPC). Little work has been done recently on

FPH, but some research has been directed into the

potential of using powdered hydrolysates in food

formulations. Many studies have resulted in fish

protein hydrolysates with excellent functional

properties. However, taste defects, specifically

bitterness, and process economics are still major

limiting factors for FPH applications.

This review gives an overview of the differ-

ent techniques for production of fish protein hy-

drolysates, past and present research on their prop-

erties, and various methods to study the extent of

hydrolysis and product functionality.

II. THE BIOCHEMICAL

CHARACTERISTICS OF FISH MUSCLE

PROTEIN

In foods, a protein is traditionally categorized

as a fibrous or globular protein based on its ter-

tiary conformation. Each type of food protein has

a unique molecular structure that determines its

functional properties, in addition to a range of

environmental conditions over which it exhibits

such properties.

6

These factors and their effect on

functionality are discussed in more detail later in

this review.

The functional and structural properties of

food proteins thus vary tremendously, and to fully

understand the process of protein hydrolysis it is

crucial to have a good understanding of the nature

of the protein substrate and the hydrolyzing agent.

During protein hydrolysate manufacture, the pro-

tein substrate is hydrolyzed by either a proteolytic

enzyme or an acid or base.

Our diet contains a wide variety of proteins

from different sources. It is generally accepted

that the relative concentration of dietary essential

amino acids is the major factor determining the

nutritional value of food protein.

7

Proteins de-

rived from animal sources are considered to be

nutritionally superior to those from plants be-

cause they contain a better balance of the dietary

essential amino acids. Of these egg and milk pro-

teins (casein) are frequently used as reference

proteins for evaluating protein quality. Proteins

derived from meat and poultry muscle are also of

very high quality and fish muscle proteins are

equally nutritious.

8

Fish muscle contains an ex-

cellent amino acid composition and is an excel-

lent source of nutritive and easily digestible pro-

teins.

9,10

However, because fish is extremely

perishable and because chemical composition can

vary, the utilization of fish as a basic raw food

material presents unique food processing prob-

lems.

11

The muscle of different animals is very simi-

lar, containing similar protein and similar amino

acid profiles. There are slight differences between

fish muscle and the muscle of land animals. These

are mainly associated with the differences in

muscle structure required for swimming and buoy-

ancy. Fish are supported by a mass of water, thus

the muscle fibers require less structural support

than those in land animals. Because of this, fish

muscle tends to have less connective tissue than

muscles from terrestrial animals, resulting in more

tender texture. Also, because of the unique move-

ment of fish, the structural arrangement of muscle

fibers is quite different from terrestrial animals. A

large fraction of commercially utilized fish stocks

are cold adapted or poikilothermic, and because

of this their muscle proteins have different bio-

chemical properties compared with those of en-

dothermic animals.

12

Poikilothermic characteris-

tics of fish proteins make them more heat sensitive

than mammalian muscle proteins, with a greater

tendency to denature at elevated temperatures.

Downloaded by [Texas A&M University Libraries] at 11:28 12 January 2016

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

45

Fish muscle proteins from cold water species are

more prone to denaturation than those from tropi-

cal waters.

13,14

The T-50 values (temperature re-

quired for 50% denaturation) of fish muscle pro-

teins are also influenced by pH and were reported

to be 29 to 35°C at pH 7.0 and 11 to 27°C at pH

5.5.

15

Protein composition in muscles varies by

muscle type. Of the three types (striated, smooth,

and cardiac muscle) of muscles, the striated

muscles are the predominant form in fish. Striated

muscle tissue is arranged into muscle fibers that

are bound together by a connective tissue to make

a fiber bundle. Fish muscle has “white” and “dark”

meat.

15

The white meat is generally more abun-

dant, contains less lipids than the dark meat, and

is the most widely consumed type of muscle tis-

sue. It is composed of about 18 to 23% of protein,

depending on the species and time of harvesting.

Fish proteins can be divided further into different

groups based on their solubility. About 70 to 80%

of fish muscle are structural proteins. These struc-

tural protein are soluble in cold neutral salt solu-

tions of fairly high ionic strength. The remaining

20 to 30% contain sarcoplasmic proteins that are

soluble in water and dilute buffers, and a final

part of the structural protein, 2 to 3%, being in-

soluble connective tissue proteins.

11

Recent stud-

ies, however, challenge these generally accepted

solubility data, showing that the muscle protein

components can be highly soluble at low ionic

strenghts.

16,17

Myofibrillar proteins are the primary food

proteins of fish, comprising 66 to 77% of the total

protein in fish meat. The myofibril protein com-

plexes contain myosin and actin. These are the

main components of the thick filament, and thin

filament, respectively. Myosin comprises 50 to

60% of the myofibrillar contractile proteins, and

actin only 15 to 30%.

12,15

Myosin is the most

abundant of the single muscle proteins, making

up around 38% of the total, and is a large mol-

ecule containing two identical heavy chains

(223 kDa) and two light chains (22 and 18 kDa).

The molecule has two identical globular head

regions that incorporate the light chains and a

significant fraction of the heavy chains. The tails

of the heavy chains form very long α-helices that

wrap around each other

18

(Figure 1). Myosin can

be cleaved by proteases at two sites on the mol-

ecule, one recognized by both trypsin and chy-

motrypsin and the other by papain. Papain cleaves

near the head region, releasing the head from the

tail. Trypsin and chymotrypsin cleave further from

the head, dividing the molecule into two compo-

nents called the heavy meromyosin (with the head

region) and the light meromyosin, both with dif-

ferent functional properties.

Myosin molecules are connected via their head

region to the polymerized actin molecules in the

thin filaments due to the ATPase activity of the

head molecules. This complex is called actomyo-

sin and is responsible for muscle contraction and

relaxation. Actomyosin plays a major role in de-

termining the quality of fish meat because it is

quite labile and easily affected during processing

and storage. For example, during frozen storage

the actomyosin becomes progressively less soluble

and the flesh becomes increasingly tougher.

19

The thin filament is a complex of actin mol-

ecules making a double helix. Tropomyosin sits

within the grooves of the thin filaments and two

FIGURE 1. Fish myosine molecule.

Downloaded by [Texas A&M University Libraries] at 11:28 12 January 2016

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

46

troponin molecules bind the actin filament at each

helical repeat. Actin is the most prominent pro-

tein of the three protein in the thin filaments,

making up about 13% of the total muscle pro-

teins. Actin occurs in two forms, G-actin, a spheri-

cal monomer, and F-actin, a large polymer that

connects to myosin. The thin filaments play a

very important role by regulating muscle contrac-

tion. From the point of view of muscle biochem-

istry, thin filaments are very important, however,

their content is low in meat and their role with

respect to food processing has not been studied

completely. Other contractile proteins of interest

are C-protein, α-, and β-actinin, connectin and

paramyosin; however, they are of limited interest

as food proteins. With respect to protein hydroly-

sis, the myofibrillar protein myosin, actin, or ac-

tomyosin are subject to enzymic cleavage and are

the greatest focus here.

III. PROTEIN HYDROLYSIS

Proteolytic modification of food proteins to

improve palatability and storage stability of the

available protein resources is an ancient technol-

ogy.

20

Hydrolysates can be defined as proteins

that are chemically or enzymatically broken down

into peptides of varying sizes.

21

Protein hydroly-

sates are produced for a wide variety of uses in

the food industry, including milk replacers, pro-

tein supplements, stabilizers in beverages and fla-

vor enhancers in confectionery products. The

benefits of hydrolyzing food proteins to make

functional protein ingredients and nutritional

supplements is a more recent technology, with the

first commercially available protein hydrolysates

appearing only around the late 1940s. Although

production is massive worldwide, the proper con-

trol of the process and the exact mechanism be-

hind protein hydrolysis is in most cases not fully

understood. Recent advances have given research-

ers insight into the connection between the pro-

cess/extent of hydrolysis and the physicochemi-

cal mechanisms responsible for specific functional

properties of the hydrolyzed protein. Recent re-

search on enzyme catalysis has also aided with

the proper selection of enzyme catalysts and pro-

cessing conditions to obtain better control over

the reaction and characteristics of the final prod-

uct.

Chemical and biological methods are the most

widely used for protein hydrolysis with chemical

hydrolysis used more commonly in industrial prac-

tices. Biological processes using added enzymes

are employed more frequently, and enzyme hy-

drolysis holds the most promise for the future

because it results in products of high functionality

and nutritive value. The chemical and biological

hydrolysis are discussed in more detail below,

with an emphasis on hydrolysis with added en-

zymes. In addition, there are many potential tech-

niques for extracting protein from animal tissue.

These include the use of aqueous and organic

solvents; the conventional processes of cooking,

pressing, drying, and hot oil extraction.

22

The

extraction of protein by means of solvent is also

worth mentioning due to its industrial and histori-

cal importance for fish protein recovery.

A. Chemical Methods for Protein

Hydrolysis

1. Chemical Extraction: The Making of

Fish Protein Concentrate

The extraction methods mentioned above,

other than the chemical and biological hydrolysis

methods, do not hydrolyze protein. They are used

primarily to concentrate intact protein by the re-

moval of water and oil from the substrate. The

method of solvent extraction has been frequently

employed when producing fish protein concen-

trate (FPC). The development of FPC was one of

the earliest attempts to recover fish protein from

processing waste and to produce a protein ingre-

dient from underutilized species. FPC was the

precursor to the field of enzyme hydrolysis of fish

proteins. A small but extensive research program

on the large-scale production of FPC by the Bu-

reau of Commercial Fisheries, now the National

Marine Fisheries Service (NMFS) of the Depart-

ment of the Commerce, began in 1961. The gen-

eral aim of the program was to study the manufac-

ture and use of FPC as a solution to global protein

malnutrition and as a potential economic stimulus

to the American fishing industry.

23

Solvent-ex-

Downloaded by [Texas A&M University Libraries] at 11:28 12 January 2016

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

47

tracted FPC (type A FPC) is produced by using

primarily isopropanol or azeotropic extraction with

ethylene dichloride, although other solvents such

as ethanol have been used successfully as well. A

standard process presented by Sikorski and

Naczk

24

shown in Figure 2 is to grind a whole or

eviscerated fish, extract it with isopropanol at a

low temperature (20 to 30°C) for 50 min, then

collect the supernatant and extract it twice again,

first at 75°C for 90 min in isopropanol and then at

75°C for 70 min with azeotropic isopropanol. The

final supernatant fraction is collected, dried, milled,

and screened to separate out bone particles. The

final product has a high biological value and is

colorless and odorless, with less than 1% lipids.

The problem with type A FPC is that it is not

readily soluble or dispersible in foods and has

poor emulsification properties.

9,25,26

Dubrow et al.

27

FIGURE 2. A production scheme for fish protein concentrate. (Adapted from Ref. 24.)

Downloaded by [Texas A&M University Libraries] at 11:28 12 January 2016

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

48

reported that FPC produced at higher tempera-

tures (50°C) compared with lower temperatures

(20°C) had significantly lower emulsifying prop-

erties, but both had very poor solubility. General

poor functionality, off-flavors the high cost of

production, and traces of solvent in the final prod-

uct made solvent extracted FPC commercially

unsuccessful despite concerted efforts.

3,28

Al-

though FPC lacks solubility, it reportedly has

good foaming properties over a wide range of pH

(pH 2 to 11), making strong, stable foams.

29–31

Despite problems with protein functionality, sol-

vent extraction is the method of choice for the

abundant fatty pelagic fish species such as sar-

dine, herring, and capelin because the protein is

effectively separated from the lipids, thereby re-

ducing stability problems normally associated with

residual oxidizable lipid. For fatty fish, isopro-

panol was a slightly more efficient solvent than

ethanol considering the residual amounts of lip-

ids, but absolute ethanol produced FPC of lighter

color and a neutral flavor.

32

Many studies with FPC have also been con-

ducted with solvent-extracted FPC as a substrate

for enzyme hydrolysis, both to defat the substrate

and to make it more accessible to enzymatic hy-

drolysis, with excellent functional and nutritional

properties.

5,25,33,34,35,36

However, enzymatic hy-

drolysis using FPC as a starting substrate resulted

in loss of some functional properties because of

excessive protein breakdown but increased nitro-

gen solubility.

30

Taste and odor problems are

generally minimized with a FPC starting mate-

rial.

33

Recent studies with solvent-extracted FPC

have produced FPC with better protein function-

ality. For example, recently Vareltzis et al.

37

stud-

ied the addition of ethanol-extracted FPC made

from sardine to hamburger patties and found that

the overall functional properties (water binding

and cooking yield) and the penetration depth and

shear force value of the hamburger increased with

the addition of FPC. However the hamburgers

had a slightly unfavorable fishy flavor. Hoyle and

Merritt

5

found that herring protein extracted with

ethanol in a similar manner and then hydrolyzed

with either Alcalase or papain produced a hy-

drolysate with a markedly reduced bitterness and

less fishy odor.

2. The Chemical Hydrolysis Process

Chemical hydrolysis of proteins is achieved

by cleaving peptide bonds with either acid or

base. Several processes have been proposed for

the acid or alkaline hydrolysis of fish.

33

This has

been the method of choice in the past for the

industry primarily because it is relatively inex-

pensive and quite simple to conduct. There are,

however, many limitations to food ingredients

using this method. Chemical hydrolysis tends to

be a difficult process to control and almost invari-

ably leads to products with variable chemical

composition and functional properties.

21,38

Pro-

tein hydrolysis with strong chemicals and sol-

vents is performed at extreme temperatures and

pH and generally yield products with reduced

nutritional qualities, poor functionality, and re-

stricted to use as flavor enhancers.

39,40

a. Acid Hydrolysis

Acid hydrolysis of proteins is used more com-

monly than hydrolysis under alkaline conditions.

A vast majority of hydrolyzed proteins consumed

in the U.S. are prepared by acid hydrolysis, mostly

from inexpensive vegetable protein sources that

otherwise would have poor nutritive and little

functional value in foods. Although the process is

harsh and hard to control, it is still the preferred

method for hydrolyzed vegetable proteins. Hy-

drolyzed vegetable protein, which are widely used

for flavor and taste enhancement properties, re-

quire extensive acid hydrolysis.

38

Applications of

hydrolyzed vegetable proteins are primarily as

flavoring agents in processed meat, crackers, and

soup mixes. Acid hydrolysis of fish protein has

usually involved reacting fish proteins with hy-

drochloric acid, or in some cases sulfuric acid,

and the proteins are completely hydrolyzed at

high temperature, and often high pressure. The

hydrolysate is then neutralized to pH 6.0 to 7.0

and concentrated to either a paste or further dried.

41

Because the product is hydrolyzed extensively,

its primary functional property is high solubility.

Total hydrolysis of fish protein substrate can be

achieved in 18 h at 118°C in 6N hydrochloric

acid.

42

In addition, following the neutralization of

Downloaded by [Texas A&M University Libraries] at 11:28 12 January 2016

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

49

the digest, the hydrolysate contains large amount

of salt (NaCl), which can make the product unpal-

atable and interferes with functionality in food

systems. Another drawback of acid hydrolysis is

the destruction of tryptophan, which is an essen-

tial amino acid. Orlova et al.

43

proposed an acid

hydrolysis process of whole fish, where steam

distillation is used to remove aromatic substances

followed by filtration then concentration. The

concentrate was used in dehydrated soup cubes

and as a microbial media.

43

The acid hydrolysis is

also widely utilized to convert underutilized and

secondary raw material from fish into fertilizer

due to the low production cost and resulting ex-

tensive hydrolysis.

b. Alkali Hydrolysis

The use of alkali reactants, primarily sodium

hydroxide, to hydrolyze protein often results in

poor functionality and more importantly can ad-

versely affect the nutritive value of the hydroly-

sate. Despite this, limited alkali treatment is used

in the food industry to recover and solubilize a

broad range of proteins. For example, mechani-

cally deboned turkey residue (MDTR) includes a

significant proportion of alkali-soluble proteins

that can be recovered by alkali treatment and used

in food applications. Fonkwe and Singh

44

dis-

cussed the use of alkali extraction to recover

MDTR with an alkaline sodium chloride solution

but found it to be unsuitable due to low recovery.

Alkaline hydrolysis of fish proteins has primarily

used FPC as the starting substrate. During alka-

line hydrolysis of fish protein, rapid cleavage to

large water-soluble polypeptides takes place, fol-

lowed by further degradation at a slower rate.

Alkali treatment can aid in modifying the proper-

ties of insoluble FPC.

24

Tannenbaum et al.

45,46

have studied the alkaline process for hydrolyzing

insoluble FPC and its applications. They devel-

oped a small-scale batch process that utilizes high

pH (12.5) and 95°C for 20 min. The product

consisted of large peptides, some relatively in-

soluble at the isoelectric point, but with an overall

improvement in functionality with respect to the

original FPC. Use of the solubilized FPC as a

milk substitute gave a product far superior to that

obtained with FPC starting material, which had

poor solubility and dispersibility.

Several deleterious reactions occur in alka-

line solutions during hydrolysis. These are initi-

ated by hydrogen abstraction from the alpha car-

bon of an amino acid and include racemization of

L-amino acids, which produces D-amino acids,

which are not absorbed by humans. Also, disul-

fide bonds are split with loss of cysteine, serine,

and threonine via β-elimination reactions and

formations of lysinoalanine, ornithinoalanine,

lanthionine, and β-amino alanine can also oc-

cur.

31

Some of these elimination and addition re-

actions may lead to the formation of toxic sub-

stances (e.g., lysinoalanine) that are highly

undesirable in foods.

47,48

Alkaline hydrolysis re-

action products have an inhibiting effect on pro-

teolytic enzymes, reducing the rate of hydroly-

sis.

49

Some of the possible reaction products that

may form during alkali hydrolysis are shown in

Figure 3.

24

High collagen solubility is also ob-

served with alkali treatment.

50

B. Biochemical Methods for Fish Protein

Hydrolysis

Biochemical hydrolysis to produce fish or

other food protein hydrolysates is performed by

utilizing enzymes to hydrolyze peptide bonds.

This can be done via proteolytic enzymes already

present in the fish viscera and muscle (endog-

enous proteases), or by adding enzymes from other

sources. To understand the process of enzymatic

hydrolysis, it is very important to understand the

nature and activity of proteolytic enzymes.

1. Proteolytic Enzymes

Enzymes are biochemical catalysts vital for

living beings, because they accelerate chemical

reactions between organic constituents within the

cells that otherwise would take an extremely long

time to complete. In food science and technology

enzymes are exploited to perform desired func-

tions in processing and analysis and to facilitate

the conversions of raw materials into higher-qual-

ity, more desirable foodstuffs.

51

Enzymes make

this possible because the active site of an enzyme

Downloaded by [Texas A&M University Libraries] at 11:28 12 January 2016

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

50

FIGURE 3. Possible chemicals that may form in the alkali-treated proteins.

is highly specific for certain substrates. Enzymes

catalyze only one specific reaction and function

by forming a complex with the substrate whose

transformation they catalyze.

Enzymes used by the food industry and in

food research are predominantly hydrolases, most

of which are carbohydrases, followed by pro-

teases and lipases. Proteases are among the best

characterized enzymes. Proteolytic enzyme prepa-

rations are economically the most important group

of enzymes, and their use is well established in

the food industry.

52

Proteases are categorized ac-

cording to the specificity of the peptide bonds

they attack (hydrolyze) and the mechanism by

which they act.

48

Four major classes of proteases

are known. They are designated by the principal

functional group in their active site: serine, thiol,

carboxyl and metallo.

53

Proteases are character-

ized further by their hydrolyzing mechanism into

endoproteinases or exopeptidases. The endo-

proteinases cleave/hydrolyze the peptide bonds

within protein molecules, usually at specific resi-

dues to produce relatively large peptides. The

exopeptidases systematically remove amino acids

from either the N terminus, called aminopepti-

dases, or the C terminus, called carboxypepti-

dases, by hydrolyzing the terminal peptide bonds.

In food protein hydrolysis, endoproteinases are

always used, but occasionally endoproteinases are

combined with exopeptidases to achieve a more

complete degradation.

20

Although the four classes of proteases men-

tioned above have different catalytic mechanisms,

they all share a common transition state (interme-

diate) during catalysis. To discuss enzyme kinet-

ics in any detail would require a separate review,

and this is not intended here. However, it is im-

portant to know the basic steps in enzyme cataly-

sis and to understand the mechanism of protein

hydrolysis. Some proteases preferentially cata-

lyze the hydrolysis of bonds adjacent to a particu-

lar amino acid residue, while others are less spe-

cific. The catalysis by proteases occurs primarily

as three consecutive reactions: (1) the formation

of the Michaelis complex between the original

peptide chain and the enzyme, (2) cleavage of the

peptide bond to liberate one of the two peptides,

and (3) a nucleophilic attack on the remains of the

complex to split off the other peptide and to re-

constitute the free enzyme.

20,54

The hydrolysis of

peptide bonds leads to an increase in the numbers

of ionizable groups (NH

3

+

and COO

-

), with a con-

comitant increase in hydrophobicity and net

charge, a decrease in molecular size of the polypep-

tide chain, and an alteration of the molecular struc-

ture leading to the exposure of the buried hydro-

phobic interior to the aqueous environment.

55–58

Giving the substrate the symbol S, the enzyme E

and the peptides in the reaction P, the overall

mechanism can be presented as:

E S ES EP H P

EOHPHP

k

k

k

k

HO

+←→→+−

′

→+−+−

′

1

1

2

3

2

–

Downloaded by [Texas A&M University Libraries] at 11:28 12 January 2016

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

51

This enzyme-substrate complex may dissoci-

ate back to reactant substrate and free enzyme, or

to free enzyme and product molecules. In other

words, classic Michaelis-Menten kinetics apply.

20

The generally accepted mechanism for proteases

indicates that the second step is the rate-determin-

ing step, thus k

2

primarily determines the overall

reaction speed, and K

m

is more or less equal to the

true dissociation constant. This simple mecha-

nism does not, however, deal with the detailed

question of how the enzyme and substrate are

bound or what molecular configurations lead to

product formation. To fully understand the ca-

talysis, a fairly detailed explanation is in order,

which is not the purpose of this review.

Enzymatic hydrolysis of proteins is a complex

process because of several peptide bonds and their

specific accessibility to enzymatic reactions.

47

The

specificity of enzymes is not the only factor that

affects the peptide profile of the final product.

Environmental factors such as temperature and pH

play an important role. Both temperature and pH

can greatly affect the enzyme reaction kinetics, and

the effect of these factors is different for each

enzyme. Generally, there is an optimum combina-

tion of both pH and T, where an enzyme is the most

active. Temperature and pH extremes deactivate

the enzymes by denaturing them.

2. Autolytic Hydrolysis

Biochemical production of fish protein hy-

drolysates may be carried out by employing an

autolytic process. An autolytic process depends

on the action of the digestive enzymes of the fish

itself. There are no enzyme costs involved, and it

is a simple operation.

59

The end product of au-

tolytic hydrolysis is generally a fairly viscous

liquid rich in free amino acids and small peptides.

The digestive enzymes in question are primarily

the serine proteases trypsin and chymotrypsin,

and the thiol protease pepsin, all major enzymes

of fish viscera and digestive tract. Lysosomal

proteases, or catheptic enzymes, present in fish

muscle cells also contribute to proteolytic break-

down to some extent.

The endogenous enzymes in autolytic hydroly-

sis are a very complex mixture of enzymes, all

with different activity requirements, which result

in end products of different molecular profiles.

Another complication is that the presence of cer-

tain digestive enzymes and their concentration

may be highly seasonal, gender and age specific,

and can vary tremendously within a species as

well as between species. These variations make it

very hard to control the hydrolytic process, and

direct the production of hydrolysates with spe-

cific molecular properties. Autolytic methods such

as chemical methods often result in a final prod-

uct with bad functionality. Despite these prob-

lems, endogenous proteolytic enzymes are used

to produce hydrolyzed products, specifically fish

sauces and fish silage.

The production of fish sauce preceded fish

silage production and is the major fermented fish

product presently consumed in the world. Its pro-

duction has thousands of years of tradition in

Asia, and it is also known to have been produced

in Mediterranean countries in ancient times. Pres-

ently, fish sauce is used mainly as a condiment on

rice dishes like the popular Nuoc-Nam produced

in Vietnam, and the annual production in South-

east Asia is about 250,000 metric tons.

60

The

production of fish sauce does not require elabo-

rate processing equipment. The substrate is usu-

ally fish from one or more pelagic species, such

as anchovies or sardines, or minced whole fish of

low commercial value. The substrate is immersed

in a solution containing high concentrations of

salt (20 to 40%) and at relatively high tempera-

tures, preferably ambient tropical temperatures.

In the case of whole fish, the visceral proteolytic

enzymes start by hydrolyzing the stomach con-

tents, then work their way through the stomach

wall, and finally reach the muscle tissue, where

they join with catheptic enzymes to hydrolyze

fish muscle proteins. The pH of the fish sauce

process is usually neutral, because no base or acid

is added to the reaction mixture. The acid-depen-

dent proteolytic enzymes, such as pepsin and the

catheptic enzyme, contribute little to fish sauce

production. The endogenous serine proteases very

slowly breakdown the fish muscle for 6 to 12

months (Nuoc-Mam) under anaerobic conditions.

This slow but extensive breakdown results in a

liquefied fish sauce composed predominantly of

free amino acids, with up to 50% nitrogen recov-

Downloaded by [Texas A&M University Libraries] at 11:28 12 January 2016

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

52

ery. The high concentration of salt is responsible

for the slow hydrolysis because this slows the

activity of the proteolytic enzymes. More impor-

tantly, the high salt concentration and anaerobio-

sis totally inhibits growth of spoilage microor-

ganisms once the salt has fully penetrated the

tissue.

61

Lower concentrations of salt, however,

result in sauces with higher yield, lower levels of

volatile acids, and better balanced composition of

amino acids.

62

During autolysis to produce fish

sauce, a lipid phase, an aqueous soluble phase

that contains much protein but little lipid, and

insoluble sediment of protein and lipid is formed.

63

After the hydrolysis is completed, the liquid pro-

tein hydrolysate is tapped, filtered, and bottled,

with the final product containing up to 10% free

amino acids and low-molecular-weight peptides,

and 25% salt.

26,60

Although the production of fish

sauce does not improve the nutritive value of the

protein, the keeping quality is greatly increased

and organoleptic characteristics are generally

improved.

64

The process of manufacturing fish silage is

different, but the product shares many character-

istics with fish sauce. The production of fish si-

lage was not started until the middle of this cen-

tury, and it is far from being as widely employed

as fish sauce production. The application of fish

silage is primarily for animal feed production

instead of food applications. The process is rapid

and enzymes involved are very effective in pro-

ducing oil and proteins fractions that are readily

separated. The substrate is usually secondary raw

material from fish processing or underutilized fish

species. The substrate is mixed with strong min-

eral acids or organic acids such as formic acid to

acidify the mixture below pH 4. At this pH the

serine proteases are generally inactive, but pepsin

and the catheptic enzymes are highly active. The

pepsin content can be very high in the visceral

portion of fish, and the enzyme is primarily re-

sponsible for fish silage production. Under acidic

conditions the active endogenous enzymes par-

tially hydrolyze the fish over several weeks to

produce a slurry containing up to 12% amino

acids and peptides. Usually about 80% of the

protein in acid fish silage become solubilized af-

ter 1 week at temperatures around 23 to 30°C.

65

The rate is primarily dependent on conditions

such as ambient temperature and relative amounts

of the visceral organs present. The processing

time is much shorter than for fish sauce because

no salt is added.

26,60

The production of fish silage

using lactic acid bacteria as the hydrolyzing agent

has been reported.

66,67

The bacterial fermentation

is initiated by mixing minced or chopped fish

with a fermentable sugar that favors the growth of

lactic acid bacteria, which is advantageous be-

cause the bacteria produces acid and antimicro-

bial factors that inhibit competing bacteria.

65

The feed applications of fish silage are prima-

rily limited to young animals due to the extensive

hydrolysis of the proteins. For fish silage to be

incorporated successfully in animal feeds, it has

to contain the majority of the nitrogen fraction as

intact proteins or peptides rather than as free amino

acids, which are less well absorbed. A shorter

processing time and added commercial proteases

may be useful in such instances. Also, problems

connected with the development of bitterness in

the hydrolyzed silage can make the product highly

unpalatable not only for humans but also animals

fed feeds rich in fish silage. The utilization of fish

silage as a primary protein source in fish feeds has

been neither fully investigated nor commercially

successful; however, it is incorporated into diets

for pigs, poultry, and mink.

67

Research on fish hydrolysates made with en-

dogenous enzymes for human food applications

has been very limited. Fish sauce is almost the

only autolytically produced food of aquatic ori-

gin. The main reason for this is fairly straightfor-

ward. To produce a functional protein hydroly-

sate with specific properties, a good knowledge

of the enzymes involved is crucial. Endogenous

enzymes in fish are a complex and highly variable

mixture, and thus the properties of functional pro-

tein hydrolysates so prepared may vary greatly

under the same reaction conditions. Also, in the

U.S. the sale of processed fish foods containing

visceral material of any kind is prohibited by the

FDA. Despite this, some work on developing fish

silage for human consumption has been conducted.

In 1972, Malcolm B. Hale and a group of scien-

tists at NMFS and the University of Maryland

conducted a comprehensive study on making func-

tional FPH by enzymatic hydrolysis for human

consumption.

33

This study involved autolysis of

Downloaded by [Texas A&M University Libraries] at 11:28 12 January 2016

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

53

red hake (Urophycis chuss), a relatively lean fish,

and alewife (Alosa pseudoharengus), a very fatty

fish. The autolysis of raw hake was conducted at

optimal conditions for the native enzymes, 50°C

and pH 7.0, for 24 h where fish was 50% of the

total slurry. The resulting hydrolysate was either

spray dried or tested as a concentrate. The aver-

age yield of dry solids for hake was lower than for

any other proteolytic enzyme employed, 10.0%

(dry solubles/wet fish), compared with the high of

14.3% from using Alcalase. Similarly, the chemi-

cal score attained for soluble hydrolysate were

quite low due to low tryptophan content that is

correlated with a low recovery. The protein effi-

ciency ratios for both red hake and alewife hy-

drolysates were essentially equivalent to that of

casein. Also, the inclusion of insoluble solids in

the final product resulted in very high fat content.

The results for lipid pressed alewife were similar.

However, by lowering the reaction period to 4 h

and raising the temperature to 55°C, a satisfactory

product with good nutritional value was prepared.

Both the red hake and alewife were only 50 to

70% soluble, requiring substantial additions of

commercial enzymes, at uneconomic levels, to

become fully soluble. The alewife hydrolysate

also suffered from very fishy taste; however, the

red hake hydrolysate had a less fishy taste and

odor. Food applications of the products obtained

by Hale and co-workers were limited and could

be used primarily as a protein supplement in cul-

tures where its taste would be acceptable and the

caloric value of the lipid desirable.

33

Shahidi et al.

59

hydrolyzed ground capelin

(Mallotus villosus) by endogenous enzymes and

found that it enhanced the overall extraction of

the fish protein at both acid and alkaline pH, as

both acid and alkaline proteases are present in

fish muscle and viscera. The protein recovery of

hydrolysates produced autolytically was, however,

considerably lower compared with commercial

enzymes, 22.9% compared with 70.6% with

Alcalase. A recent study by Cui

68

with chum

salmon (Oncorhynchus keta) mince and visceral

content showed a surprisingly extensive and rapid

hydrolysis at an acid pH and 37°C. The hydroly-

sate also showed a marked difference in the mo-

lecular weight distribution of peptides when com-

pared with a commercial pepsin hydrolysis. The

native acid enzymes resulted in a product with the

majority of peptides of lower molecular weight

than the pepsin hydrolysate under the same ex-

perimental conditions. This indicates that protein

hydrolysates can be obtained through autolysis

very efficiently at relatively mild temperatures.

The functional properties of the product were,

however, not investigated.

The main limitation of work performed on

autolytic hydrolysis of food proteins is the lack of

research on functional properties. Studies have

shown that protein recovery can be adequate and

that nutritional requirements are good, but infor-

mation on functional properties of the resulting

hydrolysate is very important to successfully evalu-

ate its use in formulated foods.

3. Enzymatic Hydrolysis of Fish Muscle

Proteins with Added Enzymes

Using added enzymes to hydrolyze food pro-

teins is a process of considerable importance used

to improve or modify the physicochemical, func-

tional, and sensory properties of the native pro-

tein without jeopardizing its nutritive value, and

often protein absorption is improved. These en-

zyme-based processes occur under mild condi-

tions over a series of stages and do not produce

hydrolytic degradation products via racemization

reactions observed with both acid and alkaline

hydrolysis.

69

The process of using added enzymes

instead of chemicals or endogenous enzymes of-

fers many advantages because it allows good con-

trol of the hydrolysis and thereby the properties of

the resulting products.

59

Processes can be designed

to take advantage of substrate specificity and the

relative reaction rates of different enzymes under

the reaction conditions employed. The physico-

chemical and functional properties of hydrolyzed

fish proteins are discussed separately in a later

section.

Enzymatic hydrolysis has been employed on

a variety of different proteins derived from live-

stock and poultry meat,

39,44,47,70,71

milk,

57,72–76

and

plants.

77,78

Hydrolysis of fish and other aquatic

foods is also being seen more frequently in the

literature. Several different aquatic protein sources

have been investigated for the production of func-

Downloaded by [Texas A&M University Libraries] at 11:28 12 January 2016

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

54

tional fish protein hydrolysates. These include

Rastelliger canagurta and Barbus carnaticus

both Indian tropical fishes,

79,80

hake (Urophycis

chuss),

10,25,33

shark (Isurus oxyrinchus),

81,82

sardine (Sardina pilchardus),

35,36,83,84

herring

(Clupus harengus),

5

crayfish,

85

lobster (Panulirus

spp.),

86

pollack (Theragra chalcogramma),

87

cape-

lin (Mallotus villosus),

59

dogfish (Squalus

acanthias),

88

chum salmon (Oncorhynchus keta),

68

Pacific whiting (Merluccius productus),

89

and

Atlantic salmon (Salmo salar).

90

It can readily be

seen from the list above that the majority of the

sources represent underutilized species or are

connected to utilization of processing wastes.

Enzymatic hydrolysis of fish protein has been

employed primarily as an alternative approach for

converting underutilized fish biomass, which is

commonly used in making feed or even fertilizer

into edible protein products.

15,88

More recently,

fish processing waste, or, more appropriately,

secondary raw material, has been connected to

FPH studies. In many cases this is due to strict

government waste regulations. Many processors

are no longer allowed to discard their offal di-

rectly to sea, resulting in a very high cost of

refining the material before discarding. Second-

ary raw material is the material remaining after

fillets are removed, and if viscera is included, this

can represent something on the order of 64% of

the weight of whitefish, the protein content of this

waste being about 10%.

3

Hydrolysis of fish pro-

tein with selected proteolytic enzymes provides

the possibility of controlling cleavage degree of

protein in the substrate. Using suitable enzyme/

substrate ratios and reaction times, this permits

the production of hydrolysates with different

molecular structures and different functional prop-

erties that could find applications in various food

formulations.

82

The hydrolytic process and reaction condi-

tions differ between different substrates and en-

zymes used and also depend on the properties

desired for the hydrolysate. Most of the described

processes are conducted under research condi-

tions and may have limited applications in the

industry. Commercial production of fish protein

hydrolysates is still limited on a worldwide basis,

but has reached a significant level in a few coun-

tries, including France, Japan, and Southeast

Asia.

60

Commercial batch protein hydrolysis has

several disadvantages such as (1) high cost of

using large quantities of enzymes, (2) difficulty in

controlling the extent of reaction that can result in

nonhomogenous products consisting of fractions

of varying molecular weight, (3) low yields, and

(4) the need to inactivate enzymes by pH or heat

treatment at the end of the reaction, which adds to

the processing costs.

91

Also, the enzymes em-

ployed in the process cannot be reused.

20

Figure 4

outlines a fairly typical process for producing fish

protein hydrolysates. Each step is given a detailed

discussion below.

a. The Substrate and Its Preparation

Lean species, or material derived from them,

is the substrate of choice for enzymatic hydroly-

sis as problems with lipid oxidation can be re-

duced. From an economic standpoint, however,

the abundant underutilized pelagic fish would be

preferred. The small pelagics comprise 23% of

the world’s catch,

92

of which only 42% is used as

human food. These are mostly fatty species such

as herring, sardines, anchovies, and mackerel, and

FPH prepared from them would contain high

amounts of lipid, which would require additional

treatments such as centrifugation to remove ex-

cess fat.

93

The fewer steps that are involved in the

production, the more economically viable the

operation becomes. If a whole fish is used, it is

eviscerated and washed, then ground in a meat

grinder, usually mixed with an equal amount of

water and homogenized in a blender until a vis-

cous homologous mixture is achieved. In some

instances a buffer solution is added to the minced

fish, for example, phosphate buffer

1,88

and boric

acid-NaOH buffer.

85

The presence of buffer salts

may affect the final properties of the hydroly-

sates. In a study of whey protein hydrolysis,

Kuehler and Stine

72

decided not to buffer the

solutions because of the influence buffer salts

might have on foaming or emulsifying properties.

Processes for fatty and lean species are differ-

ent. If the FPH contains more than 1% fish fat, the

fat must either be removed by solvent extraction

or stabilized by antioxidants

3,60

such as butylated

hydroxytoluene, butylated hydroxyanisol,

5

or

propylgallate.

10

A fish protein hydrolysate with

high lipid content may darken. The formation of

Downloaded by [Texas A&M University Libraries] at 11:28 12 January 2016

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

55

brown pigments may result from aldol condensa-

tion of carbonyls produced from lipid oxidation

after reaction with basic groups in proteins.

5

Re-

searchers have developed many means of mini-

mizing the lipid content in FPH. To obtain a

product of a lipid content not exceeding 0.5% by

weight, as established by the Protein Advisory

Groups of FAO for a fish protein hydrolysate

suitable for human consumption,

94

Quaglia and

Orban

36,84

defatted ground sardines by extraction

with isopropanol three times (solvent: substrate

ratio 1:1) at 46°C for 30 min, and then homog-

enized the mixture with water. Hoyle and Merritt

5

used an ethanol (90%) extraction directly on

minced herring at the fish/ethanol ratio of 1:2 at

70°C for 30 min, then mixed with equal volume

of water, hydrolyzed the mixture, then spray dried

it. Through this procedure the lipid content was

reduced to 0.9 from 4.0% of raw herring. Also

before placing the treated substrate in the reaction

vessel, chemical agents such as NaCl, sorbic acid,

or ethanol are occasionally added to the minced

fish to minimize bacterial degradation,

24

espe-

cially if reaction conditions are at neutral or alka-

line pH. However, adding NaCl can reduce the

rate of hydrolysis, increasing reaction time. Etha-

nol can also adversely affect the reaction process

in too high concentration by inhibiting protease

activity, although sorbic acid has not been found

to affect hydrolysis in concentrations up to 0.5%.

24

b. The Choice of Enzyme

The water mince mixture is added to a reac-

tion vessel where the hydrolysis takes place. Of-

FIGURE 4. A flow sheet for the enzymatic hydrolysis of fish protein to make fish protein hydrolysate

Downloaded by [Texas A&M University Libraries] at 11:28 12 January 2016

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

56

ten a flask, ranging from 0.5 to 3 L with a close-

fitting multisocket lid, has been used. The sockets

in the lid usually carry: a stirrer, driven by a

overhead variable speed motor to ensure adequate

mixing of the system, a thermometer to monitor

temperature, a pH electrode to monitor pH, and a

“pH-stat” device, where acid or base is added to

maintain a constant pH (Figure 5). The tempera-

ture of the reaction vessel is controlled. After the

required temperature is achieved, the pH of the

slurry is adjusted to the desired value. It is impor-

tant that the mixture is well mixed and consis-

tently stirred when the pH is added to allow for

uniform distribution of the added acid or base.

Processing temperature and pH is normally se-

lected to optimize the kinetics of the selected

enzyme or enzyme mixture.

48

A commercial pro-

tease is added in varying concentrations depend-

ing on the rate of hydrolysis needed. Given a

particular enzyme and a particular substrate, any

hydrolysis process involves at least five indepen-

dent variables. These are S (protein substrate con-

centration: %N × 6.25), E/S (enzyme-substrate

ratio in % or in activity units per kg N × 6.25), pH,

T (temperature), and t (time).

95

A wide variety of commercial enzymes exist

that have been used successfully to hydrolyze fish

and other food proteins. Proteolytic enzymes from

plants and microorganisms are most suitable to

prepare fish protein hydrolysates.

26

Enzymes used

to hydrolyze fish protein have at least one com-

mon characteristic: they have to be food grade,

and, if they are of microbial origin, the producing

organism has to be non-pathogenic.

96

The choice

of enzyme(s) is usually determined by a combina-

tion of efficacy and economics.

48

The screening for a suitable enzyme in a pro-

cess or experiment is very important if the prod-

uct is to have predetermined properties. The

screening process can be conducted in a variety of

ways, and there is no standard methodology for

this selection, leaving it primarily up to the indi-

vidual researcher what method is most appropri-

ate. Good examples of selection procedures are

found in studies by Hale,

97

Cheftel et al.,

25

Arzu

et al.,

98

Rebeca et al.,

1

Baek and Cadwallader,

85

and Kristinsson and Rasco.

99

In the comprehen-

sive study by Hale,

97

the relative activities of

more than 20 commercially available proteolytic

enzymes were measured for the hydrolysis of a

washed and freeze-dried fish protein substrate

from haddock. Preliminary tests at 1 h, 40°C, and

pH 7 resulted in the plant enzyme ficin to be most

active, but with papain, also a plant enzyme, hav-

ing a much higher relative ranking. When the

enzymes were tested at 24 h the picture changed,

60% digestion (the set limit) was achieved fastest

by Pronase, which exhibited the greatest activity

per unit weight. The enzymes pepsin, papain, and

pancreatin were most suitable if the lowest cost

per unit of proteolytic activity was to be followed.

These cost estimates are less valid today due to

the commercial availability of bacterial enzymes.

Although many would prefer to use acid pro-

teases so microbial growth could be more easily

limited, they usually yield a product with low

protein yield and too excessive hydrolysis for

food use.

39,84,86

Therefore, milder enzymes at neu-

FIGURE 5. A typical enzymatic hydrolysis reaction system in the laboratory. (Adapted from Ref. 20.)

Downloaded by [Texas A&M University Libraries] at 11:28 12 January 2016

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

57

tral and slightly alkaline conditions have been

used more frequently in recent years. In some

cases, a high level of solubilization is desired.

The acid enzyme pepsin has been most successful

in solubilizing fish protein. Liu and Pigott

100

pro-

duced a high-quality, fluffy, water-soluble fish

protein hydrolysate by pepsin hydrolysis of rock-

fish fillets. Tarky et al.

101

used pepsin at 37°C and

pH 2.0 to hydrolyze the entire fish waste resulting

from filleted English sole. The final product, after

ultrafiltration and spray drying, was a creamy

white, nonhygroscopic, water-soluble hydrolysate

with low lipid content but very poor nutritional

value.

Alcalase, an alkaline enzyme produced from

Bacillus licheniformis and developed by Novo

Nordisk (Bagsvaerd, Denmark) for the detergent

industry, has been proven repeatedly by many

researchers to be one of the best enzyme used to

prepare functional FPH and other protein hydroly-

sates.

20,36,59,84,88,89

Shahidi et al.

59

successfully used

Alcalase to optimize processing conditions to

produce capelin protein hydrolysates. Alcalase-

treated hydrolysates exhibited superior protein

recovery (70.6%) compared with the alkaline pro-

tease Neutrase and papain. Alcalase-treated hy-

drolysates also had the lowest lipid content (0.18%)

and excellent functional properties. Quaglia and

Orban

36

studied the same three enzymes at opti-

mal conditions on enzymatic solubilization of

sardine proteins. Hydrolysates produced using

Alcalase and papain were almost identical in ni-

trogen recovery, which increased with increasing

enzyme concentration (70% recovery at a en-

zyme/substrate ratio of 4%). Neutrase-treated

hydrolysates at the same ratio had only over 20%

nitrogen recovery. Hydrolysates from Alcalase

and papain also exhibited better functional prop-

erties and high nutritional value than those from

Neutrase. Improved nitrogen recovery of fish pro-

tein hydrolysates with increase of protease con-

centration has been reported elsewhere.

1,79

Alcalase

and Neutrase were studied further recently by

Benjakul and Morrissey

89

on Pacific whiting solid

waste at pH 9.5, 60°C and pH 7.0, 55°C, respec-

tively. Alcalase had a considerably higher activ-

ity than Neutrase and led to a more efficient hy-

drolysis. Optimum conditions for Alcalase were

20 Anson Units (AU)/kg, 1 h reaction time, and

waste:buffer ratio of 1:1 (w/v) at 60°C and pH

9.5. The resulting hydrolysate had a high protein

content with excellent nitrogen yield (up to 70%)

and an amino acid composition comparable to

fish muscle. Further, Alcalase was found to be

the most cost-effective enzyme out of five en-

zyme preparations tested to hydrolyzed salmon

muscle proteins.

99

Other new enzyme prepara-

tions have shown excellent potential for hydro-

lyzing fish proteins to make highly functional

FPH, including Flavourzyme 1000L (Novo

Nordisk, Bagsvaerd, Denmark), Corolase 7089

(Rohm Enzymes; Somerset, NJ) and Corolase

PN-L (Rohm Enzymes, Somerset, NJ).

99

In an extensive paper,

33

Hale reported the

effects of various processing conditions and com-

mercially available proteolytic enzymes on yield

and composition of water-soluble fish protein

hydrolysates. He concluded that the hydrolysis of

raw hake (Urophycis chuss) with Alcalase at pH

8.5 or above gave the best balance of essential

amino acids and a high yield of soluble product,

followed by pancreatin (a mixture of serine pro-

teases). One of the first studies on added enzyme

hydrolysis of fish protein was with papain, due to

its favorable properties of pH and temperature

optima for activity.

79,80

Two fish species were

used as substrate, one freshwater, Barbus

carnaticus, and the other marine, Rastrelliger

canagurta, and studied at 40 and 55°C, and pH 5

and 7. Total solids and nitrogen recovery for both

species was high, with pH 7 having the highest

total solids and nitrogen recovery (69.7% at 55°C

for freshwater species) compared with pH 5, pos-

sibly attributed to better hydration at pH 7.

To properly compare enzyme activity on the

same substrate, it is necessary to determine the

general proteolytic activity units at specific reac-

tion conditions. Unfortunately, very few research-

ers have done this, and most compare enzyme

activity on a weight basis of enzymes used in the

reaction mixture. Adding enzymes on the basis of

weight is meaningless if relative enzyme activity

is to be compared, because enzyme activity per

weight is different for each enzyme under experi-

mental conditions used. However, there exist few

studies that use and compare enzymes on the

basis of their proteolytic activity. Gonzalez-Tello

et al.

69,102

studied three proteases on whey protein

Downloaded by [Texas A&M University Libraries] at 11:28 12 January 2016

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

58

substrate by adding them to the system based on

Anson Units (AU). Unfortunately, they did not

use the three enzymes at the same AU. In addi-

tion, the activity units were obtained from the

manufacturer and not assayed by the researchers.

Also, reaction conditions used in the hydrolysis

experiments were different from the conditions

used in the enzyme assays, thus making the activ-

ity units very unreliable.

Benjakul and Morrissey

89

studied the hydroly-

sis of Neutrase and Alcalase on Pacific whiting

solid wastes by adding the enzymes to the system

based on AU units. This study has the same limi-

tation as the studies by Gonzalez-Tello et al.

69,102

by using reaction conditions different than those

used to assay the enzyme for proteolytic activity

and relying on enzyme units provided by the sup-

plier instead of assaying the enzymes themselves.

Other studies on fish protein hydrolysis add en-

zymes according to AU units and also suffer from

these same limitations.

59,82

A study by Beddows

and Ardeshir

103

is the most carefully conducted

study in the literature with respect to using stan-

dardized relative enzyme activity. They assayed

three proteases, bromelain, ficin, and papain, by

using BApNA (Benzoyl-Arg-para-Nitroanilide) to

obtain some indication of the relative proteolytic

activities of these enzymes. They then added the

enzymes to a system of minced Ikanbilis

(Stolephorus sp.), a tropical fish, at the same ac-

tivity units as based on their assay. The assay,

however, involved different reaction conditions

than the hydrolysis experiment, which limited its

reliability. Assaying enzymes with BApNA also

only estimates the trypsin activity of the enzyme

preparation, not their general proteolytic activity.

Using BapNA, therefore, gives a less accurate

and and probably underestimated value of en-

zyme activity. In a research conducted by

Kristinsson and Rasco,

99

where salmon muscle

proteins were hydrolyzed, the enzymes were as-

sayed under the same reaction conditions as they

were used in the hydrolysis experiment. A syn-

thetic protein substrate for proteolytic activity,

Azocoll, was used to obtain a uniform level of

proteolytic activity for all enzymes used. Azocoll

is an insoluble cowhide preparation consisting

largely of collagen. The method is based on dye

release from the insoluble substrate Azocoll when

a proteolytic enzyme cleaves the peptide linkages

in it. The rate at which the dye is released can be

used to quantitatively measure the amount of pro-

teolytic enzyme(s) activity working in a solution

by measuring the absorbance at 520 nm. The

enzymes were then used to hydrolyze the sub-

strate, all at the same activity unit according to the

Azocoll assay, thus comparing them at the same

activity level on the same substrate. No reports in

the literature have taken this approach; however,

the use of Azocoll in fish protein hydrolysis ex-

periments has been reported by Ferreira and

Hultin.

104

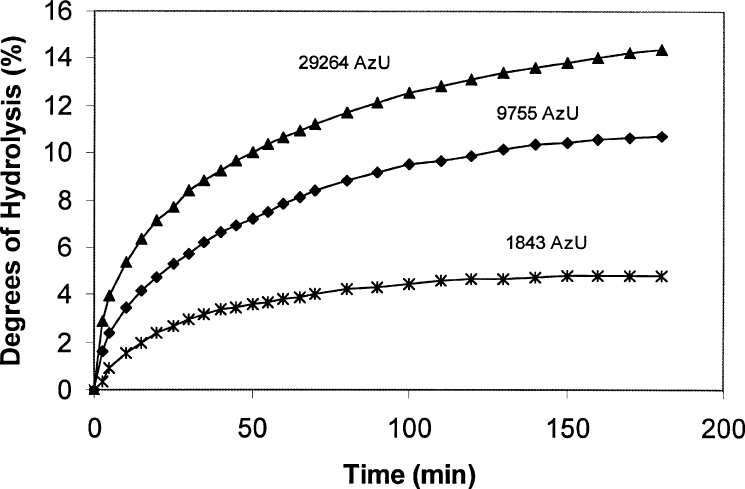

c. The Mechanism of Enzymatic Hydrolysis

The enzymatic hydrolysis of fish muscle pro-

teins is characterized by an initial rapid phase,

during which a large number of peptide bonds are

hydrolyzed, after this rate of enzymatic hydroly-

sis decreases and reaches a stationary phase where

no apparent hydrolysis takes place

59

(Figure 6).

The shape of the hydrolysis curve has been asso-

ciated with enzyme inactivation, product inhibi-

tion by hydrolysis products formed at high de-

grees of hydrolysis, a low K

m

value for the soluble

peptides that act as effective substrate competi-

tors to the unhydrolyzed fish protein,

1

and possi-

bly autodigestion of the enzyme.

105

Shahidi et

al.

59

found that a high concentration of soluble

fish peptides in the reaction mixture, released

during the initial phase of hydrolysis, reduced

both the rate of hydrolysis and the recovery of

soluble proteins. Thus, removal of hydrolysate

from the reaction mixture should enhance the

hydrolysis rate and the protein recovery.

By increasing the protease concentration, and

thereby increasing the extent of hydrolysis, re-

covery of soluble nitrogen increases,

1,71,103

al-

though increasing enzyme concentrations may not

be cost effective. Substrate concentration has also

negative effects on protein recovery. Linder et

al.

47

found that more than 8% protein concentra-

tion in the system, regardless of enzyme concen-

tration, seemed to have an inhibiting effect on

protein recovery. Baek and Cadwallader

85

reported

using Optimase to hydrolyze crayfish processing

byproducts the %DH increased as substrate con-

Downloaded by [Texas A&M University Libraries] at 11:28 12 January 2016

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

59

centration decreased to 45% (w/v), suggesting

that high %DH did not coincide with a high amount

of hydrolysate. Similarly, Surowka and Fik,

70

who

measured the production of protein hydrolysate

with Neutrase from chicken heads, reported that

hydrolysis increased as substrate concentration

decreased. Ferreira and Hultin,

104

using Newlase

A to hydrolyze cod (Gadus morhua) frames, found

that enzyme autolysis can be reduced at higher

substrate concentrations.

Because fish tissue is a very complex sub-

strate and also contains large amounts of protein-

ase inhibitors, it is impossible to explain the mecha-

nisms of protein hydrolysis in detail for this

system.

60

A kinetic study of the process is also

quite complicated due to the various types of

peptide bonds involved and their differing vulner-

ability to attack by enzymes during the hydrolytic

process.

69

Very few studies on kinetics of fish and

food protein enzymatic hydrolysis are reported.

Sakai et al.

87

conducted a kinetic study on the

hydrolysis of pollack surimi protein using a acid

protease derived from Aspergillus niger, deter-

mining the effects of temperature, pH, initial sub-

strate concentration, and enzyme concentration

on the kinetics of protein solubilization. Their

experimental data followed Michaelis-Menten

type kinetics. Michaelis-Menten kinetics has also

been observed with whey protein hydrolysis.

69

Kristinsson and Rasco

99

studied the kinetics of

five different enzyme preparations during the

hydrolysis of salmon muscle proteins and found

that the initial rate of the reaction for all enzymes

showed a linear relationship to enzyme activity.

These experiments indicated that the initial rate

constants for each enzyme tested were in the same

order. This confirmed previous studies by Hevia

et al.

106

and Cheftel et al.

25

on menhaden fish

protein as a substrate.

A kinetic model of whey protein hydrolysis

with Alcalase has been proposed, where the hy-

drolytic reaction is zero-order for substrate. The

enzyme denatures simultaneously via a second-

order reaction due to free enzymes attacking the

enzyme bound to the substrate.

69

Moreno and Cuadrado

107

hydrolyzed vegetable

proteins with Alcalase and found reaction mecha-

nism consistent with substrate inhibition and a

second-order deactivation with respect to the en-

zyme concentration. Enzyme autolysis was de-

FIGURE 6. Hydrolysis curve for salmon muscle mince with Corolase 7089 at three different activity units (AzU =

Azocoll Units).

Downloaded by [Texas A&M University Libraries] at 11:28 12 January 2016

Copyright

©

2000, CRC Press LLC — Files may be downloaded for personal use only. Reproduction of this material without

the consent of the publisher is prohibited.

60

pendent on the substrate concentration. Cheftel et

al.

25

used Pronase to hydrolyze fish protein con-