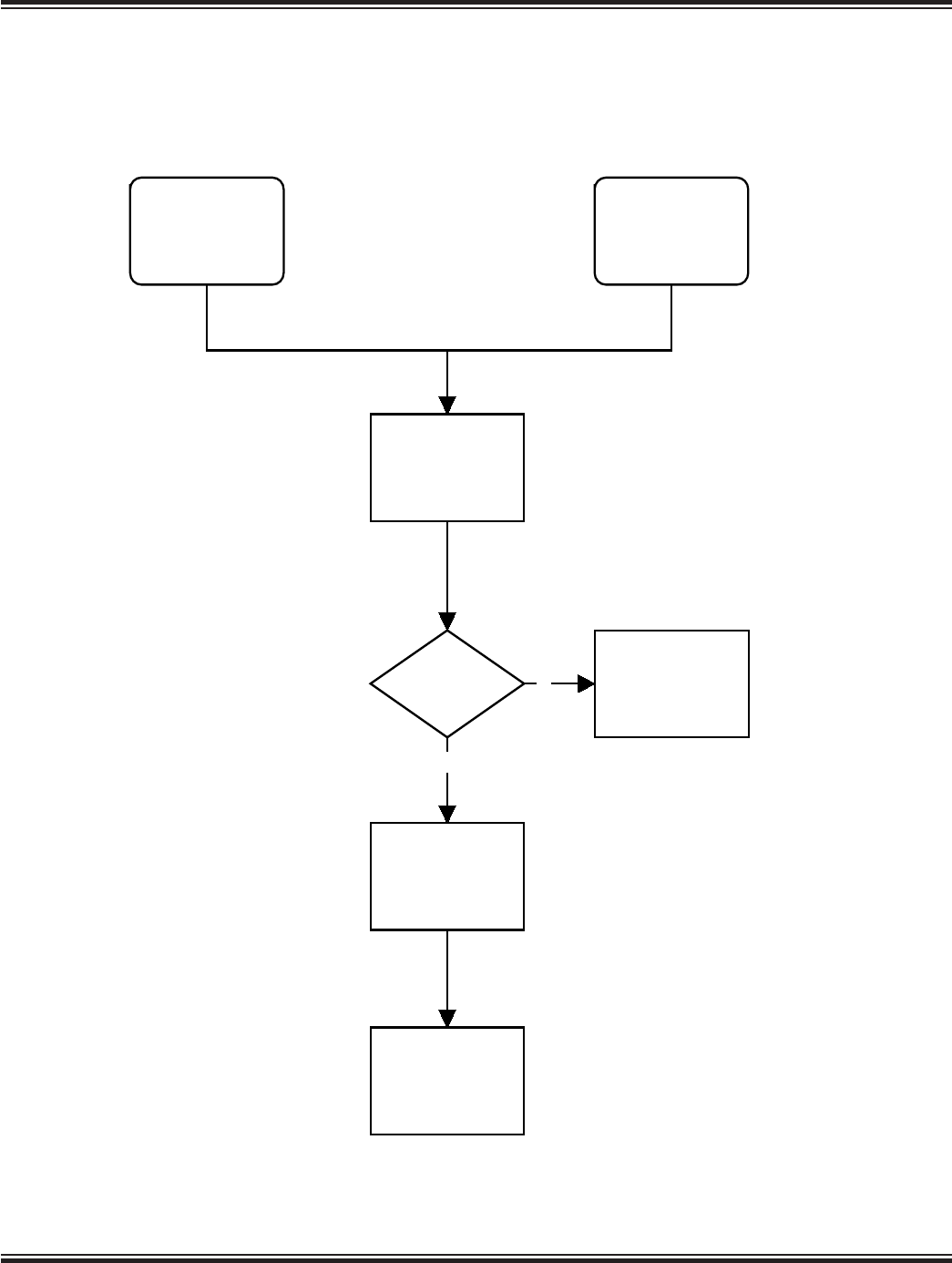

ALERT

To control temperature:WATER

To control temperature:PATIENT

•Connectbanket(s

)

•Inser t

p

atient

probe

•P ress button

Press

a

gaintos elect

Set desiredpatient

tempreature

AUTO

CONTROLOPTION

•

To monitor temperature:

•Insertpatientprobe

Press button

PATIENT

(NOTH ERAPY)

• MONITOR

SELECT MODE

SILENCE

ALARM

TEST LIGHTS

AND

A

LARM

CHECK W

A

TER FLOW.

CHECK

P

ATIENTP

ROBE.

ADDWATER

.

REMOVE

FROMUSE N

OW

.

MACHINES

HUTD

OWN.

MANUAL

AUTO

MONITOR

TEMPERA

TURE

Set

P

oint

W

ater

P

atient

°C/°F

War

ming

Cooling

Flow-OK

•Connectbanket(s)

•P ress button

Set desiredp atient

tempreature

MANUAL

•

MEDI-THERM

®

III

HYPER/HYPOTHERMIA MACHINE

MTA7900

SERVICE MANUAL

P/N 101251000 Rev A 04/10

www.gaymar.com

SERVICE MANUAL

Medi-Therm

®

III

SAFETY PRECAUTIONS

• Repairs should be performed only by qualied

personnel such as cert5ied biomedical

electronics technicians or certied clinical

engineers familiar with repair practices for

servicing medical devices and in accordance

with the Medi-Therm III Service manual.

• Always perform the FUNCTIONAL CHECK AND

SAFETY INSPECTION (section 7.3, p. 20) after

making repairs and before returning the Medi-

Therm

®

III machine to patient use.

Improper repair may result in death or

serious injury, equipment damage, or

malfunction.

Federal law restricts this device to sale by

or on the order of a physician.

RECEIVING INSPECTION

Upon receipt, unpack the Medi-Therm III machine. Save

all packing material. Perform a visual and mechanical

inspection for concealed damage by removing the

wraparound from the chassis (see page 75). If any damage

is found, notify the carrier at once and ask for a written

inspection. Photograph any damage and prepare a written

record. Failure to do this within 15 days may result in loss

of claim.

Refer to section 7.0 of this Medi-Therm III Service Manual

for additional details.

Do not return the Medi-Therm III machine to Gaymar

IndustrieswithoutrstcontactingGaymar’sTechnical

Service Department for assistance.

Telephone: Direct (716)662-2551

TollFree 1800828-7341

IMPORTANT

Before operating the Medi-Therm III machine, remove the

compressor shipping braces. See p. 88, gure B.

OPERATING INSTRUCTIONS

For more information on operating the Medi-Therm III machine,

refer to the Medi-Therm III Operator’s Manual.

Medi-Therm and Clik-Tite are registered trademarks of Gaymar Industries, Inc.

©2010. Gaymar Industries, Inc. All right reserved. www.gaymar.com

SERVICE MANUAL

Medi-Therm

®

III

i

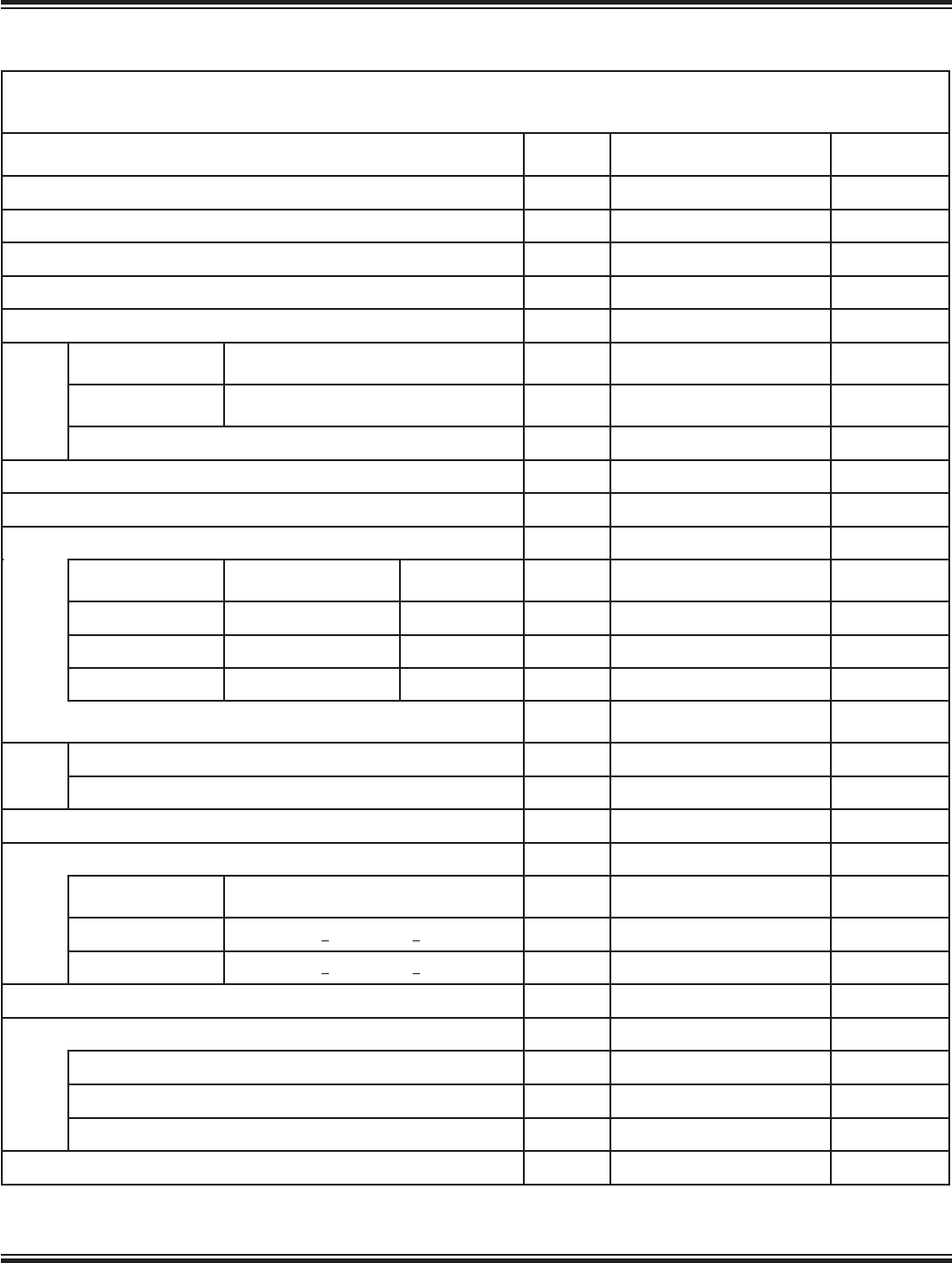

CONTENTS

Section Description ................................................................................Page

1.0 PATIENTSAFETY ..................................................................... 1

2.0 MACHINEPRECAUTIONS ..................................................... 3

3.0 REPAIRPOLICY ........................................................................ 4

3.1 In-WarrantyRepairs ............................................................. 4

3.2 Out-of-WarrantyRepairs ..................................................... 4

4.0 SPECIFICATIONS ..................................................................... 5

4.1 PhysicalSpecications .......................................................... 5

4.2 ThermalSpecications ........................................................ 5

4.3 ElectricalSpecications ....................................................... 6

5.0 PROBEINFORMATION ........................................................... 7

6.0 THEORYOFOPERATIONS .................................................... 9

6.1 Machine.................................................................................. 9

6.2 Interconnections .................................................................. 11

6.3 PowerSupply ........................................................................ 12

6.4 MachineFunctions ............................................................... 12

7.0 FUNCTIONALCHECK,SAFETYINSPECTION,

PREVENTIVE MAINTENANCE ............................................. 18

7.1 ReceivingInspection ............................................................ 18

7.2 CleaningProcedures ........................................................... 18

7.3 FunctionalCheckandSafetyInspection ........................... 20

7.4 InspectionForm ................................................................... 33

8.0 TROUBLESHOOTING&SERVICEMODES ........................ 34

8.1 ServiceModes ...................................................................... 34

8.2 TroubleshootingCharts ...................................................... 38

9.0 REPAIR PROCEDURES ........................................................... 57

9.1 RefrigerationSystem .......................................................... 57

9.2 ReplacingthePowerSupplyBoard .................................... 59

9.3 ReplacingtheControl/DisplayBoard ................................ 60

9.4 ReplacingtheTopCover ..................................................... 61

9.5 ReplacingThermostats........................................................ 62

9.6 CleaningtheFlowSwitch ................................................... 63

9.7 ReplacementParts .............................................................. 64

9.8 Shipping/RepackingInstructions ........................................ 64

10.0 REFERENCETABLES ............................................................... 65

10.1 Celsius-FahrenheitConversion .......................................... 65

10.2 Temperaturevs.Resistance ................................................ 66

11.0 SERVICEINFORMATION ....................................................... 67

TABLES

Table Description ................................................................................Page

1 HighTemperatureLimits ......................................................... 25

2 RFUErrorCodes ...................................................................... 35

3 ServiceModes ........................................................................... 36

4 Celsius/FahrenheitConversion ................................................ 65

5 Temperaturevs.Resistance ..................................................... 66

6A OperatorControls/Indicators ................................................. 68

6B OperatorControls/Indicators ................................................. 71

7 PartsList(base) ........................................................................ 77

8 PartsList(head)........................................................................ 78

9 Control/DisplayBoardPartsList ............................................ 85

10 PowerSupplyBoardPartsList ................................................ 86

CONTENTS

SERVICE MANUAL

Medi-Therm

®

III

ii

ILLUSTRATIONS

Figure Description .............................................................................. Page

1 TypicalWaterWarm-upRate ................................................... 6

2 TypicalWaterCooldownRate ................................................. 6

3 Medi-ThermIIISystem ............................................................ 8

4 MT590TestTool........................................................................ 24

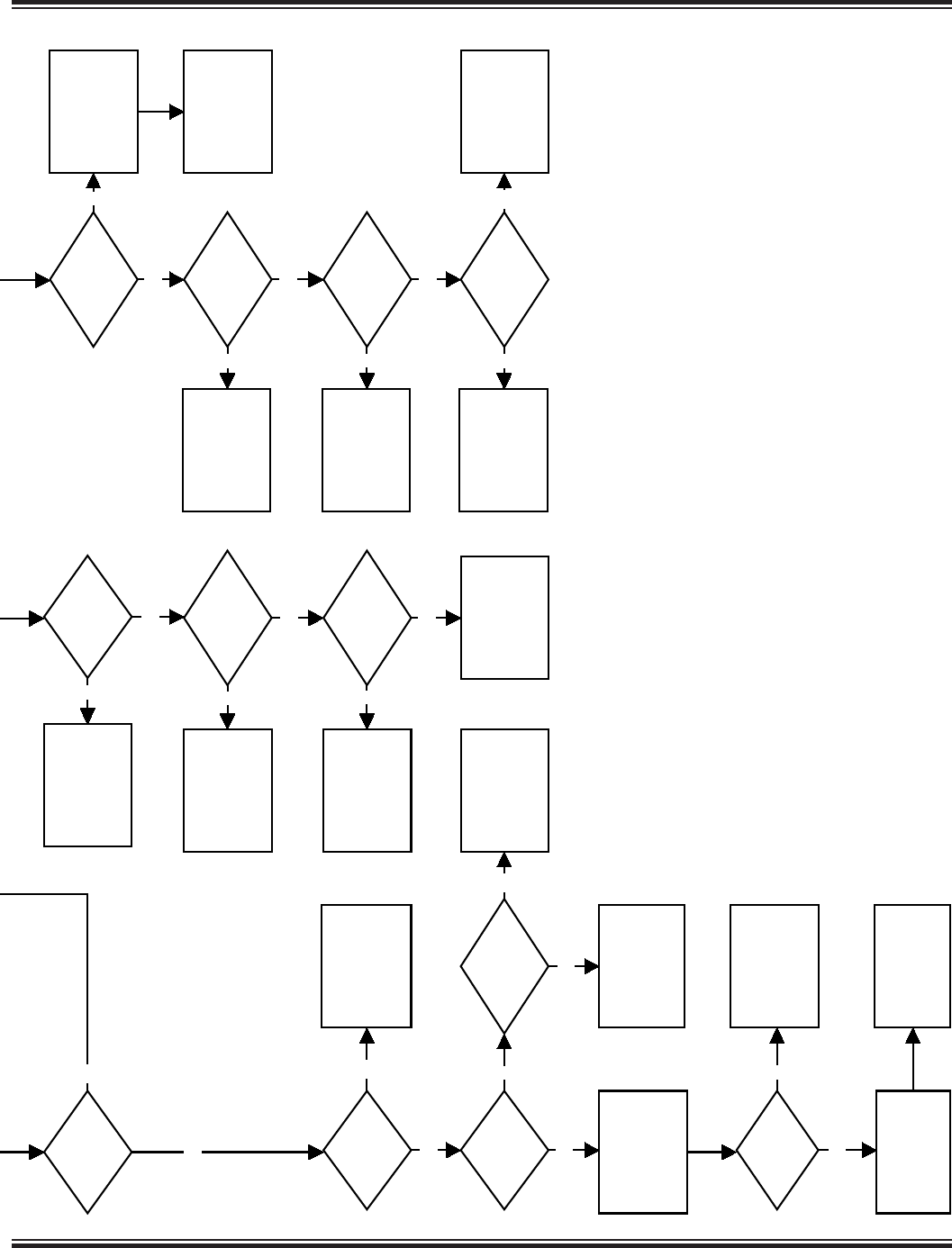

5 InitiatingServiceMode1 ........................................................ 35

6A/6L TroubleshootingCharts ........................................................... 38

6A AccessingRFUCodes ............................................................... 38

6B RFUCode1 ............................................................................... 39

6C RFUCodes2,3,–,E,andL ...................................................... 40

6D RFUCodes4,5 .......................................................................... 41

6E RFUCodes6,7 .......................................................................... 42

6F RFUCode8 ............................................................................... 43

6G RFUCode9 ............................................................................... 44

6H RFUCodeH(page1of2) ........................................................ 46

6H RFUCodeH(page2of2) ........................................................ 47

6I CheckWaterFlowAlertisOn(page1of2) .......................... 48

6I CheckWaterFlowAlertisOn(page2of2) .......................... 49

6J PumpMotorNotRunning ...................................................... 50

6K WaterWon’tHeatinAutoorManualMode(page1of2) ... 52

6K WaterWon’tHeatinAutoorManualMode(page2of2) ... 53

6L WaterWillNotCool(page1of3) .......................................... 54

6L WaterWillNotCool(page2of3) .......................................... 55

6L WaterWillNotCool(page3of3) .......................................... 56

7 FlowSwitch ............................................................................... 63

8 CircuitBoardsandConnectors(head)................................... 67

9A OperatorControls/Indicators ................................................. 68

9B OperatorControls/Indicators ................................................. 70

10 HeatingFlowDiagram ............................................................. 72

11 CoolingFlowDiagram ............................................................. 72

12 RefrigerationFlowDiagram .................................................... 73

13 TestSetup .................................................................................. 74

14 MachineDisassembly................................................................ 75

15 PartsDiagram(base) ............................................................... 76

16 PartsDiagram(head) ............................................................... 78

17 ThermostatWiringDiagram ................................................... 79

18 SystemWiringDiagram ........................................................... 81

19 PowerSupplyBoardSchematic(sheet1of3) ....................... 82

20 Control/DisplayBoardSchematic(sheet2of3) ................... 83

21 Control/DisplayBoardSchematic(sheet3of3) ................... 84

22 Control/DisplayBoard .............................................................. 85

23 PowerSupplyBoard ................................................................. 86

24 SystemBlockDiagram ............................................................. 87

25 Shipping/RepackagingInstructions ......................................... 88

FIGURES

SERVICE MANUAL

Medi-Therm

®

III

1

1.0 PATIENT SAFETY

Use the Medi-Therm III Hyper/Hypothermia machine only under the direction

of a physician.

Review the following precautions and procedures prior to each application:

• If the patient’s temperature is not responding or does not reach

the prescribed temperature in the prescribed time or deviates

from the prescribed temperature range, notify the attending

physician promptly. Failuretonotifythephysicianpromptly

mayresultindeathorseriousinjury.

• Power interruption will cause the Medi-Therm III machine to go

into a standby mode, resulting in no therapy to the patient. Follow

instructions for desired mode to resume operation. Failureto

resumetherapycouldresultindeathorseriousinjury.

• The Medi-Therm III machine is provided with a means of

checking rectal/esophageal temperature probes. When performing

the probe check, use a disposable protective sheath (Becton-

Dickinson catalog 3700 oral sheath or equivalent) on the probe.

Failuretousesheathcouldresultincross-contamination.

• When using the rate controlled Auto Moderate or Auto Gradual

modes for warming, switching to other modes, e.g. Auto Rapid or

Manual, or changing the temperature set point during the therapy

will cause the Medi-Therm to reset the therapy. Alternating

the Mode or Temperature set point may impact the

overalldurationofthetherapy.

• A physicians order is required for use of equipment. Check the

integrity of the skin according to department protocol when

regulating temperature with external devices. Frequency of

assessment and documentation will vary depending upon the

individual response of the patient. Failuretomonitorpatient

mayresultinskindamageorinappropriatepatient

temperature.

PEDIATRICS—The temperatures of infants and children are more

responsive to surface heating and cooling than adults. The smaller

the patient, the more pronounced the effect because of the

patient’s higher ratio of skin contact area to body mass.

TEMPERATURE-SENSITIVE PATIENTS—Patients with impaired

peripheral blood circulation caused by vascular diseases and

patients who are incapacitated may be more sensitive to

temperature changes than patients with more normal circulation.

OPERATING ROOM PATIENTS—Patients with poor circulation

associated with inadequate heart function, reduction in blood volume,

and constriction of peripheral blood vessels may deviate from the

normal response to the external application of heat and cold.

PATIENT SAFETY

Do not use the Medi-Therm III machine in the presence of

ammable anesthetics. Riskofexplosioncanresult.

SERVICE MANUAL

Medi-Therm

®

III

2

• Avoid placing additional heat sources between the patient and blanket/

body wrap. Skindamagecanresult.

Heat applied by the blanket/body wrap can result in a rise in skin

temperature at the areas of contact. The additional heat rise due to

electrosurgical currents owing to the dispersive electrode could

be sufcient to cause tissue injury. Each thermal effect by itself may

be completely safe, but the additive effect may be injurious.

1

Keep

additional heat sources from between the patient and the blanket/body

wrap.

• Prevent excessive and/or prolonged tissue pressure and shearing forces,

especially over boney prominences. Skindamagemayresult.

Localized skin injury due to tissue compressed between boney

prominences and uid-lled channels has occurred during prolonged

cardiovascular procedures at water temperatures well below the

scientically established epidermal burn injury threshold.

2

Local ischemia can follow the application of pressures exceeding

capillary pressure resulting in tissue necrosis. This local effect may be

enhanced by generalized impairment of the circulation, local shearing

forces and increased metabolic demand because of temperature eleva-

tion. Pathological changes may begin in two (2) hours.

• Keep the area between the patient and the blanket/body wrap dry.

Excessivemoisturemayresultinskindamage.

The application of heating or cooling may affect the toxicity of

solutions. Prep solutions have been reported to injure the skin when

allowed to remain between patients and water circulating heating

blankets/body wraps during prolonged procedures.

3

REFERENCES

1 Gendron, F. G. Unexplained Patient Burns. chap. 5, p. 87, Quest Publishing Co., 1988.

2 Scott, Stewart M. Thermal Blanket Injury in the Operating Room. Arch. Surg., vol. 94, p. 181, Feb. 1967; Crino, Marjanne H. Thermal Burns

Caused by Warming Blankets in the Operating Room. Clinical Workshop, vol. 29, pp. 149-150, Jan-Feb 1980; Gendron, Francis G. Journal

of Clinical Engineering, vol. 5, no. 1, pp. 19-26, January-March 1980; Moritz, A. R. and Henriques, Jr., F.C. Studies of Thermal Injury II. The

Relative Importance of Time and Surface Temperature in the Causation of Cutaneous Burns. Am. J. Path., 23:695, 1947; Stoll, Alice M. and

Chianta, Maria A. Method and Rating System for Evaluation of Thermal Protection. Aerospace Medicine, vol. 40, no. 11, pp. 1232-1238,

Nov. 1969; Stewart, T. P. and Magnano, S. Burns or Pressure Ulcers in the Surgical Patient. Decubitus, vol. 1, pp. 36-40, 1988.

3 Llorens, Alfred S. Reaction to povidone-iodine surgical scrub, scrub associated with radical pelvic operation. Am. J. Obstet. Gynecol., pp.

834-835, Nov. 14, 1974; Hodgkinson, Darryl J., Irons, George B. and Williams, Tiffany J., Chemical Burns and Skin Preparation Solutions.

Surgery, Gynecology & Obstetrics, vol. 17 pp. 534-536, Oct. 1978.

PATIENT SAFETY

1.0 PATIENT SAFETY

(continued)

• Place a dry absorbent sheet between the patient and the blanket

when using the plastic-like side of any blanket.

A dry absorbent sheet placed between the patient and the Hyper/

Hypothermia Blanket will absorb perspiration. Vinyl blankets and

body wraps with nonwoven fabric surfaces do not require an

absorbent sheet when using the nonwoven side toward the patient.

• Federallawrestrictsthisdevicetosalebyorontheorder

of a physician.

SERVICE MANUAL

Medi-Therm

®

III

3

MACHINE PRECAUTIONS

2.0 MACHINE

PRECAUTIONS

Disconnect power before servicing unit.Riskofelectricshock.

• Repairs should be performed only by qualied personnel such as certied biomedical

electronics technicians or certied clinical engineers familiar with repair practices for

servicing medical devices, and in accordance with the Medi-Therm III Service Manual.

Improperrepairmayresultindeathorseriousinjury,equipmentdamage,

ormalfunction.

• Always perform the FUNCTIONAL CHECK AND SAFETY INSPECTION (section 7.3, p.

20) after making repairs and before returning the Medi-Therm III machine to patient

use. Improperrepairmayresultindeathorseriousinjury,equipment

damage,ormalfunction.

• Some manufacturer’s patient probes may contain compensation resistors in series

with YSI 400 series thermistors. Do not use these probes with the Medi-Therm

III machine. Inaccuratepatienttemperaturereadoutswillresultand

inappropriatetherapymaybedelivered.

NOTE: Use only Gaymar probes or equivalent YSI 400 series probes approved for

use with medical devices.

(Refer to the list of recommended probes in section 5.0,

p. 7 PROBE INFORMATION.)

• All wire-lead, patient-connected transducer assemblies are subject to reading

error, local heating, and possible damage from high-intensity sources of RF energy.

Inadequately grounded electrosurgical equipment represents one such source, since

capacitively-coupled currents may seek alternate paths to ground through probe

cables and associated instruments. Patientburnsmayresult.

If possible, remove the probe from patient contact before activating the surgical unit or

other RF source. If probes must be used simultaneously with electrosurgical apparatus,

hazards can be reduced by selecting a temperature monitoring point which is remote

from the expected RF current path to the ground return pad.

• Do not tip machine over without rst draining the water out and unplugging the

power cord. Electricalshockordamagetothemachinecanresult.

Add distilled water only. Failuretousedistilledwatermayresultinpoormachine

performance.

• Do not use alcohol, since it is ammable. Alcohol may also accelerate blanket/body

wrap deterioration.

• Do not operate the machine without water, since damage to internal components

may result.

• Do not overll. Overlling may result in overow because the water in the blanket/

body wrap drains back into the machine when the machine is turned off. Overlling

may also result in splashing from the overow tube during transport.

SERVICE MANUAL

Medi-Therm

®

III

4

3.0 REPAIR POLICY

3.1 IN-WARRANTY

REPAIRS

3.2 OUT-OF-WARRANTY

REPAIRS

The Medi-Therm III Hyper/Hypothermia machine is warranted free of defects

in material and workmanship for a period of two (2) years, under the terms

and conditions of the Gaymar warranty in place at the time of purchase. The

compressor portion of the machine carries a ve (5) year prorated warranty.

The full warranty is available from Gaymar upon request. Medi-Therm III Hyper/

Hypothermia machines can be repaired at the factory or in the eld. Upon

customer request, a shipping carton will be provided to safely return the machine

to Gaymar or a qualied Service Center.

For customers who repair Gaymar Medi-Therm III machines at their location, this

manual contains information to allow a qualied biomedical technician, familiar

with practices for servicing medical devices, to make necessary repairs. Service

training for the Hyper/Hypothermia machine is recommended and is available

from Gaymar. For specic details, contact your Gaymar representative or the

Technical Service Department at Gaymar. (See back cover of this manual for

Gaymar telephone numbers.)

All in-warranty eld repairs must be authorized by Gaymar’s Technical Service

Department before proceeding.

The following repair options are available when local machine servicing is elected:

I . Defective Component

Replacement parts can be ordered. Specify the Gaymar part number; refer to

the Parts Lists in section 11, pp. 76–88 of this manual.

2. MachineRepairs

If the Medi-Therm III machine becomes defective and the cause of the

problem cannot be determined, the complete machine can be returned to the

factory for servicing at the purchaser’s expense. This normally represents the

most expensive repair option.

Please contact Gaymar to obtain an RG (returned goods) number prior

to returning the machine.

REPAIRS / WARRANTY

SERVICE MANUAL

Medi-Therm

®

III

5

4.1 PHYSICAL SPECIFICATIONS

SPECIFICATIONS

4.2 THERMAL SPECIFICATIONS

4.0 SPECIFICATIONS

MTA7900

Dimensions

37 in. high x 18-3/4 in. deep x 14 in. wide

(94.0 cm high x 47.6 cm deep x 35.6 cm wide)

Weight

141 lb (full); 121 lb (empty); shipping wt, 136 lb

64.0 kg (full); 54.9 kg (empty); shipping wt, 61.7 kg

Normal Reservoir Oper-

ating Volume

Approximately 10 quarts (9-1/2 liters) distilled water

Operating Ambient Tem-

perature Range

15.6ºC to 32.2ºC (60ºF to 90ºF)

Dead Head Pressure 9.0 psi max (62 kPa max)

Flow 16 gph (gallons per hour) 60.6 liters/hour) *

High Temperature Limits Fixed

(S2) & (S3)

44ºC (111.2ºF) to 49ºC (120.2ºF)

(Machine will go into REMOVE FROM USE NOW / MACHINE SHUTDOWN

condition and audible alarm will be on)

Low Temperature Limits Fixed (S1)

-3ºC (26.6ºF) to +2.5ºC (36.5ºF)

(Machine will go into REMOVE FROM USE NOW / MACHINE SHUTDOWN

condition and audible alarm will be on)

Add Water Alert Actuation Less than 8 quarts (7.6 liters) of water in the cold reservoir

Check Water Flow Alert Actuation 6 GPH

Check Probe Activation Tempera-

ture (whenever probe is used)

29ºC (84.2ºF) or above 45ºC (113ºF)

Patient Temperature Control

Range for Automatic Mode

30ºC (86.0ºF) to 41ºC (105.8ºF)

Water Temperature Control Range

for Manual Mode

4ºC (39.2ºF) to 42ºC (107.6ºF)

* Minimum ow rate through a full size Gaymar Hyper/Hypothermia Blanket

SERVICE MANUAL

Medi-Therm

®

III

6

4.2 THERMAL SPECIFICATIONS (cont'd)

4.3 ELECTRICAL SPECIFICATIONS

Figure 1—Typical water warm-up rate

(with full size blanket)

Figure 2—Typical water cooldown rate

(with full size blanket)

SPECIFICATIONS

MTA7900

Patient Temperature Measurement Accuracy

+0.5ºC, +0.9ºF

(using Gaymar 400 series probe)

Display Accuracy +0.3ºC, +0.5ºF

Display Resolution

Blanket Water Temperature 1ºC, 1ºF

Patient Temperature 0.1ºC, 0.1ºF

Controller Accuracy

Blanket Water Temperature

+0.8ºC, +1.4ºF

NOTE: At set points of 4ºC to 6ºC, this accuracy may not be

obtainable due to compressor control characteristics.

Patient Temperature +0.5ºC, +0.9ºF

Current Leakage

Chassis 100 microamps maximum

Patient Probe 50 microamps maximum

Input Voltage 120V + 10V

Frequency 60 Hz

Input Current 11.5A

Regulatory

UL416

CSA C22.2 No. 125

Electromagnetic Compatibility

Meets EN60601-1-2:1993

(CISPR 11 Classied as Class A,

Group 1 ISM Equipment)

Debrillation Proof

The Medi-Therm III MTA7900 along with its temperature probe

is a “Debrillator Proof, Type BF Applied Part” per IEC60601-1

standards.

SERVICE MANUAL

Medi-Therm

®

III

7

5.0 PROBE

INFORMATION

DisposableProbes

• DP400CE Disposable Rectal/Esophageal -

Adult/Small Child (3' [0.9 meters] long, requires adaptor);

YSI 400 series type

ProbeAdaptor

• ADP10CE Reusable adaptor cable for DP400CE: connects Gaymar

disposable probe to Gaymar or Cincinnati Sub-Zero

control unit.

ReusableProbes

• PAT101 Patient probe—Rectal/Esophageal -

Adult (10' [3.0 meters] long); YSI 400 series type

• PAT102 Patient probe—Rectal/Esophageal -

Pediatric (10' [3.0 meters] long); YSI 400 series type

• PAT108 Patient probe—Skin surface (10' [3.0 meters] long);

YSI 400 series type

PROBE INFORMATION

Some manufacturer’s patient probes may contain compensation resistors

in series with YSI 400 series thermistors. Do not use these probes with

the Medi-Therm III machine.

Inaccuratepatienttemperaturereadoutswillresultand

inappropriatetherapymaybedelivered.

NOTE: Use only Gaymar probes or equivalent YSI 400 series probes

approved for use with medical devices.

(Refer to the list of recommended probes above.)

SERVICE MANUAL

Medi-Therm

®

III

8

MEDI-THERM

®

III SYSTEM

Figure 3 - Medi-Therm III System

Hyper/Hypothermia

blanket/body wrap

Gaymar probe or equivalent YSI 400 series probe

approved for use with medical devices.

SERVICE MANUAL

Medi-Therm

®

III

9

The Gaymar Medi-Therm III machine provides a means of regulating patient

temperature by supplying temperature-controlled water through a connector

hose to a Gaymar Hyper/Hypothermia blanket/body wrap. The blanket/body wrap

provides an interface for heating or cooling the patient. A patient probe senses

patient temperature, which is displayed on the control panel. (See gure 3, p. 8.)

The Medi-Therm III machine controls output water temperature by mixing hot

and cold water using hot and cold solenoid valves under microcontroller control.

A circulating pump, heater and refrigeration unit are also utilized.

Bimetallic thermostats and associated backup circuitry limit output water

temperature independent of the microcontroller.

The feedback for control purposes depends upon the machine's operating mode.

The Medi-Therm III machine may be operated in one of three operating modes:

• In MANUAL mode, the operator sets the desired water temperature. A

temperature sensor within the machine monitors the water temperature

and the machine heats or cools the water as required to bring the water

temperature to the SET POINT temperature. The patient temperature may be

monitored by use of a patient probe connected to the patient probe jack on

the front of the unit.

• In AUTO mode, the Medi-Therm III machine automatically regulates the

patient's temperature to the selected SET POINT. The machine constantly

compares actual patient temperature with the SET POINT value, and

automatically adjusts the water temperature so that the desired patient

temperature is achieved.

• In MONITOR mode, the operator can monitor patient temperature through

the patient probe, without providing therapy.

Two gray hose sets are provided to connect multiple blankets and/or body wraps

in order to provide more body surface contact. Increased body surface contact

facilitates more efcient warming/cooling.

NOTE: When connecting a second blanket/body wrap to the Medi-Therm

III machine, check the water level prior to connecting the additional

blanket/body wrap.

Whenever the machine is on, 10 quarts of water are maintained cold in the cold

water reservoir. A cold water reservoir probe provides temperature feedback to

the microcontroller which cycles the refrigeration unit on at 5.8°C (42.5°F) and

off at 3.3°C (38.0°F).

When the water requires cooling, water is pumped from the cold water reservoir.

When the water requires heating, a cartridge heater is used to quickly heat the

water.

6.0 THEORY OF

OPERATION, SYSTEM

6.1 THEORY,

MEDI-THERM III

MACHINE

SERVICE MANUAL

Medi-Therm

®

III

10

WATER TEMPERATURE CONTROL

Hot and cold solenoid valves regulate the ow path by directing water

returning from the blanket/body wrap to either the hot or cold water reservoir.

Regulating the ow path controls the temperature of water pumped to the

blanket/body wrap. The microcontroller controls solenoid valve operation. Only

one valve may open at a time:

When the WARMING status light is lit, the hot solenoid valve is open.

Water returning from the blanket/body wrap circulates through the hot

water reservoir and is heated before being pumped back to the blanket/

body wrap. The heater, pump, and hot solenoid valve are energized. (See

g. 10, p. 72.)

When the COOLING status light is lit, the cold solenoid valve is open.

Water returns from the blanket/body wrap to the cold water reservoir

and is replenished by chilled water from the cold water reservoir

before being pumped back to the blanket/body wrap. The pump and

cold solenoid valve are energized. (See g. 11, p. 72.) The refrigeration

unit maintains the cold water reservoir temperature and operates

independently of the solenoid status.

When both the WARMING and COOLING lights are off, either the water

temperature is within 1°C (1.8°F) of the setpoint (in MANUAL mode) or the

patient temperature is within 0.5°C (0.9°F) of the setpoint (in AUTO mode).

Water temperature is controlled by alternating between heating and cooling (see

gures 10–11) with the heater cycled on and off as needed.

REFRIGERATION UNIT

The refrigeration circuit (see gure 12, p. 73) consists of two heat exchangers

operating at two pressures and two devices used to change these pressures. The

rst of these devices is the compressor which changes the gas pressure from

low to high. The other device is the capillary tube which reduces the refrigerant

pressure from high to low.

Beginning the cycle at the capillary tube, high pressure liquid refrigerant ows

in the capillary tube and is discharged into the evaporator coil. The evaporator

coil, which is a heat exchanger, receives the refrigerant as a mixture of liquid and

vapor at a pressure low enough so that it boils and absorbs heat from the water

surrounding it.

The heated refrigerant vapor then leaves the evaporator coils, enters the suction

side of the compressor and is compressed, causing its pressure and temperature

to increase. The vapor, much warmer than the ambient air, travels to the

condenser.

The condenser is the other heat exchanger. The condenser fan draws the colder

ambient air over the condenser coils and removes the heat being carried by the

refrigerant and causes it to condense back into liquid refrigerant. This completes

the cycle and the high pressure liquid refrigerant is returned to the capillary tube

to be used over again. The temperature of the water surrounding the evaporator

coil (in the cold water reservoir) is controlled by the microcontroller. The

microcontroller senses the temperature with a cold water reservoir probe and

cycles the compressor relay on and off.

6.1 THEORY OF

OPERATION,

MEDI-THERM III

MACHINE (continued)

SERVICE MANUAL

Medi-Therm

®

III

11

BACKUP SYSTEMS

Backup systems within the Medi-Therm III machine limit the temperature of

water exiting the machine to specied ranges in the event of a failure of the

control system including the microcontroller:

Maximumwatertemperature is limited by two bimetallic thermostats.

If either of these two thermostats is actuated, a REMOVE FROM USE NOW /

MACHINE SHUTDOWN circuit is triggered which:

• shuts down the pump and heater;

• lights the ALERT and the REMOVE FROM USE NOW / MACHINE

SHUTDOWN indicators; and,

• sounds the audible alarm.

In addition, if the microcontroller is operational, the compressor shuts down, the

displays blank, and the ALERT indicator and audible alarm turn on and off.

Minimum water temperature is limited by a bimetallic thermostat. If this

thermostat is actuated, a REMOVE FROM USE NOW / MACHINE SHUTDOWN

circuit is triggered, which in turn:

• shuts down the pump and heater;

• lights the ALERT and the REMOVE FROM USE NOW / MACHINE

SHUTDOWN indicators; and,

• sounds the audible alarm.

In addition, if the microcontroller is operational, the compressor shuts down,

the displays blank, and the ALERT indicator and audible alarm turn on and off.

See gure 8, p. 67 for base-to-head and control/display board-to-power supply

board connections; gure 18, p. 81 for system wiring diagram; gures 19–21,

pp. 82–84 for electrical schematics; gures 22–23, pp. 85–86 for component

layouts and part designations; and gure 24, p. 87 for the system block diagram.

CONTROL/DISPLAY BOARD AND POWER SUPPLY BOARD

The Medi-Therm III machine uses two printed circuit boards (see gure 8, p. 67):

• The control/display board contains the microcontroller circuits, the

display circuits, and all other low voltage control circuits.

• The power supply board contains the power supply, the low voltage

to high voltage interface circuits, and the REMOVE FROM USE NOW /

MACHINE SHUTDOWN backup safety circuits.

The control/display board connects to the patient probe jack J1 via P2 at J2 and

to the digital control assembly panel via P4 at J4. All other connections from the

system’s peripheral devices to the control/display board are made through the

power supply board.

A 26-pin cable connects the control/display board via P1 at J1 to the power supply

board via P3 at J4.

6.1 THEORY OF

OPERATION,

MEDI-THERM III

MACHINE (continued)

6.2 SYSTEM

COMPONENT

INTERCONNECTIONS

SERVICE MANUAL

Medi-Therm

®

III

12

Four cables connect the components in the base of the machine to the PC boards

in the head (see gure 8, p.67):

• A 9-pin connector P6 ties the water temperature probe RT2, cold

water reservoir probe RT1, ow switch S5, and level switch S4 to the

power supply board at J2 and ultimately to the control/display board.

• A 12-pinconnector P7 ties the high voltage devices (pump, heater,

hot solenoid valve SV2, cold solenoid valve SV1, and refrigeration

compressor relay K1) to the interface circuits on the power supply

board, as well as thermostats S1, S2, and S3 to the high voltage backup

circuitry on the power supply board.

• A 6-pinconnector P5 connects transformer T1 housed in the base

to the power supply circuitry at J3 on the power supply board.

• A chassisgroundharness from the control/display board connects

to the chassis.

See gure 18, p.81 for the system wiring diagram; gures 19–21, pp. 82–84 for the

electrical schematics; gures 22–23, pp. 85–86 for component layouts and part

designations; and gure 24, p. 87 for the system block diagram.

Power enters the Medi-Therm III machine through circuit breaker CB1 to feed

the refrigeration unit through relay K1. It also then enters the power supply board

at J1 to feed the hot solenoid valve, cold solenoid valve, heater and pump triacs,

the high voltage backup water temperature limiting circuits and transformer T1.

Power to drive the low voltage circuits on the control/display board is derived

from the machine’s power supplies which reside entirely on the power supply

board. The transformer T1 output is rectied and ltered to generate unregulated

positive and negative voltages. Q5, D1, L1 and associated components are

congured as a DC to DC switching regulator in a buck conguration yielding a

nominal output of +5.3 volts DC. Q6 is a linear regulator with a nominal output

of plus twelve (+12) volts DC, while Q7, also a linear regulator, delivers a nominal

output of minus twelve (-12) volts DC.

See gure 18, p. 81 for system wiring diagram; gures 19–21, pp. 82–84 for the

electrical schematics; gures 22–23, pp. 85–86 for component layouts and part

designations; and gure 24, p. 87 for the system block diagram.

The U37 microcontroller is fully dependent on the code stored in the U31

EPROM. When the machine is on, the microcontroller continually cycles through

its main program loop to perform the following:

• Thermistor output measurement (see section 6.4.1, p. 13)

• Digital control panel input (section 6.4.2, p. 13)

• Display update (section 6.4.3, p. 13)

• Peripheral input (section 6.4.4, p. 14)

• Water/Patient temperature control (section 6.4.5, p. 15)

• Cold water reservoir temperature control (section 6.4.6, p. 16)

Backup water temperature limiting is achieved independently of the

microcontroller. (See section 6.4.7, p. 16.)

6.2 SYSTEM

COMPONENT

INTERCONNECTIONS

(continued)

6.3 POWER SUPPLY

6.4 MACHINE

FUNCTIONS

SERVICE MANUAL

Medi-Therm

®

III

13

Temperature measurement is achieved using 400 series thermistor beads located

in the water path (water temperature probe RT2), the cold water reservoir (cold

water reservoir probe RT1), and in the patient via the patient probe jack J1.

Under microcontroller U37 control, each of the three beads is connected to the

current source circuitry (U38 and associated components) by a demultiplexor

U49. At the same time, the resulting output voltage created by the current

through the thermistor is presented to an amplier circuit (U39 and associated

components) via multiplexor U50. The amplied voltage is then applied to a

voltage-to-frequency converter U24. A frequency up to 100kHz is presented to

port pin P3.5 of the microcontroller. The microcontroller converts the incoming

frequency to a temperature value.

At regular intervals two compensation resistors R13 and R12 are also processed

in the same manner. These compensation resistors are precision resistors with

values at each end of the probe temperature range of 0°C (32°F) to 50°C (122°F).

The values from the precision resistors are used to compensate for circuit drift.

User input is entered via a digital control panel. The input from the buttons is

decoded by U45. The “data available” line of U45 is tied to the microcontroller

port pin P3.3. When a button press is decoded and debounced by U45, the

“data available” line goes high and the microcontroller responds by inputting the

decoded value.

For display of measured and set point temperatures, 7 segment LED displays are

utilized:

• The set point display is driven by driver chip U48. The microcontroller

interfaces to it via the data bus at addresses 0FFF8H, 0FFF9H, 0FFFAH,

0FFFBH.

• The patient display is driven by driver chip U6. The microcontroller

interfaces to it via the data bus at addresses 0FFF4H, 0FFF5H, 0FFF6H,

0FFF7H.

• The water temperature display is driven by driver chip U5. The

microcontroller interfaces to it via the data bus at addresses 0FFECH,

0FFEDH, 0FFEEH, 0FFEFH.

6.4.1 THERMISTOR

OUTPUT

MEASUREMENT

6.4.2 DIGITAL CONTROL

PANEL INPUT

6.4.3 DISPLAY UPDATE

SERVICE MANUAL

Medi-Therm

®

III

14

All alarm and status indicators are lit by LED bars driven by inverter/driver IC’s:

• The alarm latch U53 is the interface between the microcontroller

and the ALERT, ADD WATER, CHECK PROBE, CHECK FLOW, REMOVE

FROM USE NOW / MACHINE SHUTDOWN, SELECT, °F and °C drivers

via the data bus at address 0FFBFH. A high signal written to the latch

by the microcontroller activates the individual inverter/drivers to

light the corresponding indicator.

• The mode display latch U54 is the interface between the

microcontroller and the COOLING, WARMING, FLOW-OK, AUTO,

MANUAL, and MONITOR drivers via the data bus at address 0FFDFH.

A high signal written to the latch by the microcontroller activates

the individual inverter/drivers.

• The control option display latch U64 is the interface between the

microcontroller and the GRADUAL, MODERATE, and RAPID drivers via

the databus at address FDFFH. A high signal written to the latch by

the microcontroller activates the individual drivers.

• The control latch U51 is the interface between the microcontroller

and the two leader light drivers via the data bus at address 0FF7FH.

When this latch is selected, a low signal on the data line from the

microcontroller causes a high signal on the latch output Therefore,

these two LED bar displays are “active low” in the eyes of the

microcontroller in contrast to all the other LED bar displays of the

machine.

The audible alarm is driven either by a high signal from the control latch U51

(from the microcontroller via the data bus at address 0FF7FH) or a high RFU

IN signal from Q10 on the power supply board. A low data line signal from the

microcontroller to U51 causes a high signal on the latch output. Therefore, the

alarm is “active low” in the eyes of the microcontroller. Transistor Q2 activates

the alarm.

The input buffer U55 is the interface between the microcontroller (via the data

bus at a “read” address of 0FFFEH) and the input signals from the ow switch S5

and the level switch S4 (which travel from the base through the power supply

board), the probe presence switch within the patient probe jack J1, and the

service mode button S3 on the control/display board. The lines to the buffer from

the peripheral devices are default high (via pull-up resistors).

The level switch S4 will pull its buffer input line low when it senses a sufcient

water level.

The ow switch S5 will pull its buffer input line low when it senses sufcient ow.

The probe presence switch within J1 will pull its buffer input line low when it

senses the presence of the patient probe.

Pressing the service mode switch S3 on the control/display board will pull its

buffer input line low.

6.4.3 DISPLAY UPDATE

(continued)

6.4.4 PERIPHERAL INPUT

SERVICE MANUAL

Medi-Therm

®

III

15

If the machine is in MANUAL mode, the water temperature as sensed by the

water temperature probe is used as the feedback signal for controlling the water

temperature to the MANUAL mode set point temperature.

If the machine is in AUTO mode, the patient temperature as sensed by the patient

probe connected to the patient probe jack is used as the feedback signal for

controlling the patient temperature to the AUTO mode set point temperature.

The machine accomplishes this by adjusting the water temperature. The water

temperature the machine uses in AUTO mode is dependent on the CONTROL

OPTION setting selected and if COOLING or WARMING is desired.

When COOLING the patient:

RAPID - the coldest water is used for cooling - as low as 4°C (39°F). This may

not be the most comfortable setting for the patient.

MODERATE - Water temperature is limited to 15°C (27°F) below the patient's

temperature. This will provide an improved comfort setting to the patient.

GRADUAL - Water temperature is limited to 10°C (18°F) below the patient's

temperature. This will provide the optimal comfort setting to the patient.

When WARMING the patient:

RAPID - the highest allowable water temperature is used for warming - as

high as 42°C (107.6°F). This is the fastest warming mode the machine can

provide.

MODERATE - The patient temperature will increase at a rate of 1°C (1.8°F)

in a period of 3 hours (0.33°C/Hr [0.6°F/Hr]).

GRADUAL - The patient temperature will increase at a rate of 1°C (1.8°F) in

a period of 6 hours (0.17°C/Hr [0.3°F/Hr]).

When using AUTO MODERATE and AUTO GRADUAL for patient warming,

NO MANUAL INTERVENTION is required once the patient set point

temperature has been selected for warming.

When WARMING a patient in MODERATE or GRADUAL modes, water

temperature is limited to a maximum of 42.0°C (107.6°F) and a minimum which

is determined by the current control option selected 15.0°C [27°F] below the

patient temperature in MODERATE mode and 10.0°C [18°F] below the patient

temperature in GRADUAL mode).

If the patient temperature deviates from the warming rate specied by the

CONTROL OPTION selected (Moderate and Gradual only) by 1.0°C (1.8°F) the

following will occur:

• the PATIENT temperature will ash;

• the ALERT led will ash; and;

• the audible alarm will toggle

Once the patient temperature returns to within 1.0°C (1.8°F) of the warming

rate specied by the CONTROL OPTION selected, the PATIENT temperature and

ALERT light will stop ashing and the audible will silence.

NOTE: If the control MODE or SET POINT is changed while this alarm is

occuring, the alarm will be reset.

NOTE: If the control MODE or SET POINT is changed while in Auto-Gradual

or Auto-Moderate control mode, this may impact the overall time period

of the therapy depending on when in the hourly cycle the mode is inter

rupted. The therapy time duration is also dependent on the patient’s

temperature at the time the Auto-Moderate or Auto-Gradual control

modes are re-selected.

For water temperature control, the microcontroller outputs a pulse train to

each solenoid valve and the heater. The pulse train duty cycle depends on the

magnitude and sense of the control signal calculated by the microcontroller.

6.4.5 WATER / PATIENT

TEMPERATURE

CONTROL

SERVICE MANUAL

Medi-Therm

®

III

16

Pin 11 of U51 on the control/display board and U8 and Q9 of the power supply

board control the cold solenoid valve while pin 9 of U51 on the control/display

board and U7 and Q8 of the power supply board control the hot solenoid valve.

Pin 8 of U51 on the control/display board and U2 and Q4 of the power supply

board control the circulating pump. Pin 7 of U51 on the control/display board and

U1 and Q3 of the power supply board control power to the heater.

The control latch U51 on the control/display board is the interface between

the microcontroller (via the data bus at address 0FF7FH) and the refrigeration

compressor relay driver on the power supply board. A high signal on the

appropriate data line causes a low signal at pin 6 of U51 on the control/display

board, which then activates Q12 on the power supply board. Q12 on the power

supply board is the interface between the control/display board and the coil of

the power relay K1 located in the machine base. The microcontroller switches

power through the relay to the refrigeration compressor at cut-out and cut-in

temperatures of 3.3°C (38°F) and 5.8°C (42.5°F). These temperatures are sensed

by the cold water reservoir probe RTl located in the water reservoir. (See gure

12, p. 73.) Control of the cold water reservoir temperature takes place whenever

the machine is on.

The power supply board includes the REMOVE FROM USE NOW / MACHINE

SHUTDOWN circuitry, which includes U3, U4, U5, U6, U9, U10, D2, D3, Q1, Q2,

their interconnected components, and xed, nonadjustable thermostats S2, S3,

and S1 located in the base. Under normal circumstances, Q1 and Q2 are kept

turned on by the action of R7, C10, and D4 and R5, C15, and D5 to complete

the conduction path for the heater and pump. If the water temperature falls into

the low temperature limit range, S1 will open. If the water temperature rises

into the high temperature limits ranges, S2 and/or S3 will open. (See section 4.2

Thermal Specication table, page 5, for the correct high or low temperature limits

6.4.6 COLD WATER

RESERVOIR

TEMPERATURE

CONTROL

6.4.7 BACK-UP WATER

TEMPERATURE

LIMITING

That is, while the solenoids and heater are either on or off, the ratio of on time

to off time is proportional to the calculated control signal amplitude. For large

differences between set point and probe temperatures, the output to the cold

solenoid will be on and the output to the hot solenoid/heater combination will be

off, or vice-versa. For differences approaching zero, the output pulse train will be

applied to the hot solenoid and cold solenoid in a complementary fashion, with

the on times and off times automatically adjusted to maintain a probe temperature

equal to the set point, or the output pulse train will be applied to the heater (with

the hot solenoid remaining open), with the on times and off times of the heater

automatically adjusted to maintain a probe temperature equal to the set point.

The circulating pump is energized whenever the unit is in AUTO or

MANUAL modes.

The control latch U51 on the control/display board is the interface between the

microcontroller (via the data bus at address 0FF7FH) and the peripheral drivers on

the power supply board.

Interface circuitry on the power supply board consists of U1, U2, U7, U8, Q3, Q4,

Q8, Q9, and associated components. U1, U2, U7, and U8 are optically coupled

triac drivers used to control their respective triacs (Q3, Q4, Q8, and Q9); these

combinations provide electrical isolation between the low voltage microcontroller

control circuits and the line voltage circuits.

The heater, pump, hot solenoid valve, and cold solenoid valve are individually

controlled by the microcontroller through latch U51 on the control/display board.

A high signal on the data line from the microcontroller causes a low signal on the

appropriate output line of U51 which then sinks current from the power supply

board to activate the peripheral devices.

SERVICE MANUAL

Medi-Therm

®

III

17

6.4.7 BACK-UP WATER

TEMPERATURE

LIMITING (continued)

* RFU = REMOVE FROM USE NOW / MACHINE SHUTDOWN

THEORY OF OPERATION

with corresponding model number of your machine.) When any one of these

thermostats opens, it directly interrupts the circuit and shuts off the pump and

heater; at the same time, full line voltage will appear between J1-2 and J1-3. In this

case, U5 and U10 will be turned on by the action of R4, D3, and associated parts

while U3 and U9 will be turned on by the action of R6, D2, and associated parts.

U5 prevents Q2 from turning on and U3 prevents Q1 from turning on even if the

open thermostat(s) closes again. The output of either U9 or U10, through buffer

Q10, signals the microcontroller that a thermostat has tripped and that a REMOVE

FROM USE NOW / MACHINE SHUTDOWN condition has resulted. Thus, should

any thermostat (S1, S2, or S3) trip, the heater and pump are shut off and the

microcontroller is notied.

On the control/display board, a high signal from Q10 of the power supply board

feeds Q2 to drive the audible alarm, feeds driver U62 to light the REMOVE FROM

USE NOW / MACHINE SHUTDOWN LED, and feeds driver U60 to light the ALERT

LED. All this is done independent of the microcontroller. This same signal is sent

to port pin P3.2 of the microcontroller Q3.

If the microcontroller is operational at the event of a high signal from Q10 of the

power supply board, the signal at P3.2 causes the microcontroller to shut off the

7 segment displays, ash the ALERT LED and light the REMOVE FROM USE NOW /

MACHINE SHUTDOWN LED, toggle the audible alarm, store the appropriate RFU*

code indicating the reason for the shutdown, turn off the heater and pump triacs

Q3 and Q4, turn off the solenoid triacs Q8 and Q9, and turn off the compressor

transistor Q12. Anytime the microcontroller goes into a shutdown condition it

also sends an output signal from port pin P3.4, through U40 of the control/display

board, to command, via Q11, U4, and U6 on the power supply board, a REMOVE

FROM USE NOW / MACHINE SHUTDOWN condition. The process of turning

off the heater and pump triacs Q3 and Q4 by the microcontroller removes

power from the REMOVE FROM USE NOW / MACHINE SHUTDOWN circuitry

on the power supply board which then allows the indicators on the control/

display board to toggle under microcontroller control. This shutdown condition

by the microcontroller program will remain until the machine is powered down.

If, upon machine turn on, the fault condition still exists, attempting to resume

therapy (which would turn on the pump and possibly heater) will replace power

to the REMOVE FROM USE NOW / MACHINE SHUTDOWN circuits on the power

supply board and cause the REMOVE FROM USE NOW / MACHINE SHUTDOWN

condition to recur.

Also, if during normal operation, the microcontroller senses internal problems, it

will attempt a shutdown as described above. (See table 2, section 8.1, p. 35.)

If the microcontroller is nonoperational at the event of a signal from Q10 of

the power supply board, the user is notied of the REMOVE FROM USE NOW /

MACHINE SHUTDOWN condition by the fact that the above mentioned indicators

are on continuously. In addition, there are separate, redundant circuits on the

power supply board, each triggered by any of the thermostats, that insure that

the pump and heater remain off even if the thermostat cools sufciently to close

again. The REMOVE FROM USE NOW / MACHINE SHUTDOWN condition remains

latched and can be cleared only by an operator intervention in the form of turning

the machine circuit breaker off. If, upon machine turn on, the fault condition still

exists, attempting to resume therapy will cause the REMOVE FROM USE NOW /

MACHINE SHUTDOWN condition to recur.

SERVICE MANUAL

Medi-Therm

®

III

18

Concealed Damage

After unpacking the Medi-Therm III machine, inspect the machine for concealed

damage. Save all packing material and carefully describe or photograph the

damage. Notify the carrier at once and ask for an inspection (in writing). Failure

to do this within 15 days may result in loss of claim. Do not return the machine to

GAYMAR — call Gaymar's Technical Service Department for advice.

Before placing the Medi-Therm III machine into service, perform a FUNCTIONAL

CHECK AND SAFETY INSPECTION (pp. 20 to 33).

IMPORTANT

BeforeoperatingtheMedi-ThermIIImachine,removethe

compressorshippingbraces.(Seep.88,gureB.)

Fluid System

Use distilled water to retard algae growth and mineral buildup. Change the

distilled water monthly or more often depending upon use.

The water circulation system, including reusable blankets, should be cleaned every

month to retard algae growth.

To clean the uid system, drain the machine and prepare an algaecidal solution

according to manufacturer’s instructions. Use Gaymar product catalog MTA33.

Add the solution to the machine, attach blankets, set the machine in MANUAL

mode to a setpoint temperature of 10°C (50°F) and circulate the solution for 12

hours. Drain the solution and rell the machine with distilled water.

• Do not use bleach (sodium hypochlorite).

Bleachwilldamagetheheatingelementinthemachine,

whichcouldresultinexcessiveleakagecurrent.

Compressor

Dirt that has accumulated on the condenser coils and cooling ns within the

machine will reduce the efciency of the compressor and should be removed with

a vacuum cleaner or compressed air hose. This will require removal of the rear

bafe assembly. This should be checked monthly or more frequently depending

upon use. (See gure 14, p. 75.)

7.0 FUNCTIONAL CHECK, SAFETY INSPECTION, AND PREVENTIVE MAINTENANCE

7.1 RECEIVING

INSPECTION

PROCEDURES

7.2 CLEANING

PROCEDURES

RECEIVING INSPECTION

& CLEANING PROCEDURES

SERVICE MANUAL

Medi-Therm

®

III

19

Pump

Pump motor should be oiled once a year with 3-4 drops of general purpose

motor oil in the locations identied on the pump label.

Panel Exterior

Clean the control panel and panel exterior with a cloth dampened with

isopropyl alcohol.

Reusable Blankets

Outside surfaces of standard reusable blankets may be cleaned with a damp

cloth and mild detergent to prevent algae growth. To clean the insides, attach the

blankets to the machine and follow instructions for section 7.2, p. 18, CLEANING

PROCEDURES, Fluid System.

NOTE: Exposure to harsh chemicals will cause blankets to lose exibility and

resistance to cracking.

Probe Check Well

The Probe Check Well should be cleaned with a small tubular brush and

detergent, and then wiped with a commercial disinfectant.

When performing the PROBE CHECK, use a disposable protective

sheath (Becton-Dickinson catalog 3700 oral sheath or equivalent)

on the probe.

Failuretousesheathcouldresultincross-contamination.

Connector Hoses

Clean connector hose sets with a damp cloth and mild detergent. Always wipe dry.

Probes

Do not autoclave. Clean with a damp cloth and mild detergent. Wipe dry.

Probes are made of PVC. If probe must be sterilized, use any cold sterilization

means except alcohol, which may accelerate probe deterioration. Always wipe dry.

If gas sterilization is necessary, probes should be handled like any other PVC

product. Probes are made of PVC.

Reusable probes may be cleaned with a damp cloth and mild detergent. Always

wipe dry. Exposure to harsh chemicals will cause probe to lose exibility and

resistance to cracking.

Disposable probes should be discarded after use.

NOTE: Exposure to harsh chemicals will cause probe to lose exibility and

resistance to cracking. Do not use damaged temperature probes.

Discard probes having visible pinholes, cracks or abrasions.

7.2 CLEANING

PROCEDURES

(continued)

CLEANING PROCEDURES

SERVICE MANUAL

Medi-Therm

®

III

20

To assure the optimum performance, dependability and safety, the following should

be performed every twelve (12) months or as specied in the facility's preventive

maintenance program.

An Inspection Form is provided at the end of this section to facilitate and

document the inspection process. Lower case letters preceding the subheadings

within section 7.3 correspond to the lines on the INSPECTION FORM.

Always perform the FUNCTIONAL CHECK AND SAFETY INSPECTION

after making repairs and before returning the Medi-Therm III machine to

patient use.

Improperrepairmayresultindeathorseriousinjury,

equipmentdamage,ormalfunction.

The following test equipment (or equivalent) is required to perform the

preventive maintenance/functional check procedures:

• GAYMAR TPT9 Flowmeter/Temperature Tester

• GAYMAR TFC1 Thermometer (±1°C accuracy);

-2°C to +52°C range

• GAYMAR DBK9 Blanket Connector Hose

*• GAYMAR MT590 Test Tool, or

GAYMAR PRK2 Patient Temp Simulator Kit, or

Precision Decade Box (0-10K ohms, 0.2% accuracy, 1 ohm

increments)

• GAYMAR DHP901 or DHP813 Hyper/Hypothermia Blanket

*• GAYMAR MT590 Test Tool, or

6" (approximately 150 cm) Shorting Jumper

• Ground Resistance Checker

• Current Leakage Tester

• Static Control Wrist Strap

* The GAYMAR MT590 Test Tool is a dedicated test tool available from

Gaymar Industries. This tool was designed to allow for more convenient and

safer testing of the high temp backup thermostats by eliminating the need

to remove the lower wraparound cover and avoiding the use of a shorting

jumper that could be accidentally left inside the machine. In addition, the

test tool can be used to monitor input/output signals between the head and

base of the machine through the use of indicator lights. This feature can be of

great value during any troubleshooting process. This test tool also provides

a patient probe simulator which allows testing of the machine without a

precision decade box.

For more information on the MT590 Test Tool, contact the Gaymar

Technical Service Department.

7.3 FUNCTIONAL CHECK

AND SAFETY

INSPECTION

FUNCTIONAL CHECK AND

SAFETY INSPECTION

Test Equipment

Requirements

SERVICE MANUAL

Medi-Therm

®

III

21

7.3 FUNCTIONAL CHECK

AND SAFETY

INSPECTION

(continued)

FUNCTIONAL CHECK AND

SAFETY INSPECTION

Disconnect power before servicing unit. Riskofelectricalshock.

Follow the following procedures carefully, paying particular attention to test

setups. Any deviation from the setups, procedures, or test equipment may result in

incorrect or misleading results.

Before making any repairs, be sure to recheck your test setup, procedure, and test

equipment.

Test equipment should be calibrated in accordance with NIST (National Institute

of Standards and Technology) guidelines to insure accurate readings.

a) Condition of Chassis

The following inspections should be performed:

1. The chassis should be clean and relatively free of rust and corrosion.

2. Exterior screws should be tight.

3. Legends, markings, and operator instructions should be legible.

4. Dirt that has accumulated in vents and cooling ns within the

machine should be removed with a vacuum cleaner or compressed

air hose. This will require removal of the rear bafe assembly.

5. Check that the casters are tight and functioning properly.

6. The quick-disconnect ttings on the machine may become stiff and

difcult to engage. If so, apply a silicone-base lubricant to the inside

of the machine ttings and the outside of the blanket connector.

7. Clean the Probe Check Well according to the procedure described

in section 7.2, p. 19.

8. Inspect the uid system for debris and any sign of algae growth.

Clean according to Cleaning Procedures, Fluid System (section 7.2).

b) Attachment Plug

Examine the attachment plug on the line cord to be sure that it is in

good condition.

c) Line Cord and Strain Reliefs

Examine the line cord along its entire length for physical damage, such as cuts

or cracked insulation. A damaged line cord should be replaced rather than

repaired. Check the quality of the strain reliefs at both ends of the line cord.

d) Circuit Breaker

A worn out circuit breaker can be responsible for intermittent shutoffs,

with no other apparent indications of failure.

Examine the physical condition of the circuit breaker, paying particular

attention to the push-on terminals at the rear of the breaker. Terminals

should be snug. Replace breaker and/or terminals if there is discoloration

or any indications of heating.

Cycle the switch on and off several times. The switch should have a

positive engagement (“click”) for the OFF and ON positions.

SERVICE MANUAL

Medi-Therm

®

III

22

e) Condition of Lights and Alarm

Plug in the Medi-Therm III machine and turn it on. Press and hold the

TEST LIGHTS button. The right and left halves of the display panel should

light and blank alternately (along with the audible alarm). The three status

legends (FLOW OK, WARMING, and COOLING), the ALERT legend and its

four (triangular) indicators, the three mode legends, SELECT heading

should be lit, and the three AUTO/CONTROL OPTION legends should be

lit. The three temperature displays should indicate “888”, “888.8”, and

“888.8”. The two temperature scale indicators (“°C” and “°F”) and the

two lines connecting SET POINT to both the WATER and PATIENT DISPLAY

should be lit. The audible alarm should sound. Replace any LED’s which

do not light.

f) Flow

To measure the machine’s ow rate and check the ow switch actuation,

perform the following:

1. Fill machine with distilled water until green band on oat stem is

fully visible.

2. Connect the test setup shown in gure 13, p.74.

3. Turn machine on. Set machine in MANUAL mode.

4. Increase the temperature set point to light the WARMING status

light. Note the ow rate. The FLOW OK indicator should be lit.

5. Decrease the temperature set point to light the COOLING status

light. Note the ow rate. The FLOW OK indicator should be lit.

6. The ow rate in both modes should exceed 16 GPH

(60.6 liters/hr).

NOTE: If the unit has been completely drained, air can be

trapped in the pump causing the ow to be decreased.

To clear the air, turn the unit off, wait approximately

one minute, and start again from step 3.

7. Kink the hose to stop the ow. The CHECK WATER FLOW indicator

should light, the FLOW OK indicator should go out, the ALERT

indicator should ash on and off, and the audible alarm will toggle.

g) Level Switch Actuation

To test the actuation of the level switch, perform the following:

1. Fill machine with distilled water until green band on oat stem is

fully visible. The ADD WATER indicator should be off.

2. Connect a DBK9 hose to a supply tting on the machine and direct

the other end to a drain or gallon (4 liter) container.

3. Turn machine on. Set machine in MANUAL mode. Adjust the

temperature set point to 4°C (39.2°F) (COOLING status light on).

4. Allow water to drain until bobber has bottomed out on the drain

screen (about 3 quarts or 3 liters). The ADD WATER indicator should

be lit.

5. Rell machine until the green band is fully visible and verify that the

ADD WATER indicator goes out.

7.3 FUNCTIONAL CHECK

AND SAFETY

INSPECTION

(continued)

FUNCTIONAL CHECK AND

SAFETY INSPECTION

SERVICE MANUAL

Medi-Therm

®

III

23

h) Cold Water Reservoir Controller

To check the cold water reservoir controller, perform the following:

1. Fill machine with distilled water until green band on oat stem is

fully visible.

2. Connect the test setup shown in gure 13, p. 74.

NOTE: To minimize the test time for this test only, do not

connect a blanket as shown in gure 13. Connect the return line

of connector hose to the TPT9 tester.

3. Turn machine on and push the MANUAL mode button.

4. Set the Temperature Setpoint to 4°C (39.2°F).

5. Verify that the machine can supply water anywhere within the 3°C

(37.4°F) to 6°C (42.8°F) range as measured by the thermometer

and that the compressor turns off one time. (This will take 15-30

minutes, depending upon room temperature and other conditions.

The use of a blanket for this test can extend this time up to 60

minutes.)

i) Water Temperature Controller and Display Test

To check the temperature controller, perform the following:

1. Fill machine with distilled water until green band on oat stem is

fully visible.

2. Connect the test setup shown in gure 13, p. 74.

3. Turn machine on. Set in MANUAL mode.

4. Set the Temperature Setpoint to the various settings specied on the

INSPECTION FORM (section 7.4, p. 33), wait until both the COOLING

and WARMING indicators turn off and the water temperature

stabilizes, then record the temperature of the thermometer and that

shown on the display. Verify that the recorded values are within

limits outlined on INSPECTION FORM, item i.

7.3 FUNCTIONAL CHECK

AND SAFETY

INSPECTION

(continued)

FUNCTIONAL CHECK AND

SAFETY INSPECTION

SERVICE MANUAL

Medi-Therm

®

III

24

j) High Temperature Backup Thermostat Trip

Temperatures [MT590 Test Tool Procedure]

• Changes to the wiring of the high temperature backup

thermostats can defeat their operation. To verify thermostat

operation, perform the Thermostat Verication Test described in

section 7.3, item k, p. 29 after performing the following test

procedure.

• After performing the following test procedure, verify that the

MT590 Test Tool or any installed shorting jumpers have been

removed before returning the machine to patient use.

Failuretodotheabovemayresultindeathorserious

injury.

To measure trip points of the high temperature backup thermostats with an

MT590 Test Tool, perform the following steps 1-15:

1. Fill machine with distilled water until green band on oat stem is fully

visible.

j) High Temperature Backup Thermostat Trip Temperatures

The following procedure describes two different approaches for

measuring the trip points (actuation temperatures) of the machine’s

high temperature backup thermostats. Steps 1-15, pp. 24-26, should be

followed when a Gaymar MT590 Test Tool is available. For those facilities

not having access to an MT590, follow steps 1A-20A, pp. 27-28.

7.3 FUNCTIONAL CHECK

AND SAFETY

INSPECTION

(continued)

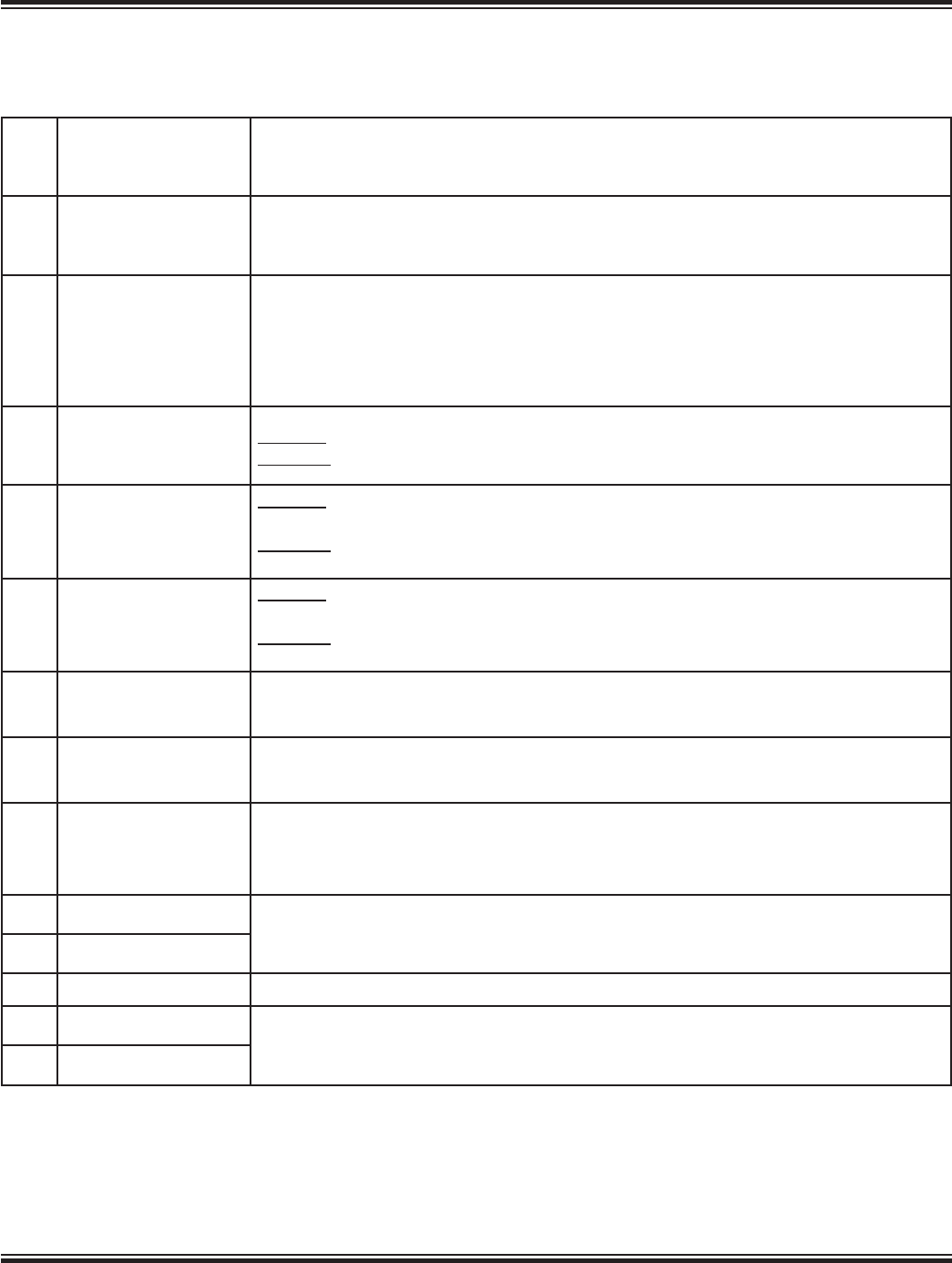

COMPRESSO R

COLD SO L.

HO TSOL.

PUMP

HEATER

J1

S2

BYPA SS

NO RM AL

R.F. U. CIRC UI TSELEC T

HIGH TEMP ERATUR E

BACKUP TH ERMO STATS

P/N 0 7 7 13 -

0 00

TE ST

PROBE

PA TIENT

S3

®

A

B

FROM MT 590TESTTOOL

TO J1 ON POWE RSUPPLY

BOAR DINHEAD

TO J1 ON

MT 590TESTTOOL

PATIENTPROBE

SIMU LATOR

37°C

32°C

Figure 4—MT590 Test Tool

FUNCTIONAL CHECK AND

SAFETY INSPECTION

MT590 TEST TOOL

POWER SUPPLY

BOARD IN HEAD

SERVICE MANUAL

Medi-Therm

®

III

25

7.3 FUNCTIONAL CHECK

AND SAFETY

INSPECTION

(continued)

FUNCTIONAL CHECK AND

SAFETY INSPECTION

2. Unplugthepowercord.

3. Connect the test setup as shown in gure 13, p. 74.

4. Connect MT590 Test Tool as shown in gure 4. Connect P7 (base) to

J1 (MT590). Connect 12 pin cable (MT590) to J1 (head, power supply

board). Plug machine in. Insure the S2 and S3 toggle switches are in the

NORMAL position.

5. Place the machine in service mode 3. Refer to section 8.1, SERVICE

MODES (pp. 34-35) for instructions on how to access service modes.

6. To insure the correct measurement of thermostat trip points, run

machine for 5 minutes in service mode 3 (see Table 3, service mode 3,

p. 37) after the blanket water temperature has reached 42°C (107.6°F).

This allows the inside of the machine to achieve normal operating

temperature. (Bottom wraparound cover must be on machine during this

test.)

7. Enter service mode 4 (see section 8.1, p. 34) from service mode 3. Mode

4 will cause the machine to heat up until one of the safety thermostats

trip.

8. Monitor the water temperature. When the ALERT and REMOVE FROM

USE NOW / MACHINE SHUTDOWN LED’s light and the audible alarm

sounds, the temperature on the thermometer should be within the high

temperature limits range. (See Table 1 below for high temperature limits.)

When the thermostat trips, record the thermometer temperature on

the INSPECTION FORM (p. 33).

(If this is the second thermostat tested, proceed to step 12. Otherwise,

proceed with step 9.)

Table 1—High Temperature Limits

9. An LED should be lit on the face of the MT590 Test Tool to indicate

an open S2 or S3 thermostat. If both LED’s are lit, proceed to step

12. (Both thermostats have tripped at the same temperature. This

is allowable so long as the water at the TPT9 was within the high

temperature limits range. See Table 1 for high temperature limits.

Otherwise, toggle the corresponding switch S2 or S3 to the bypass

position for whichever LED was lit.

10. Turn machine off.

11. Place machine in service mode 3. If machine still indicates REMOVE

FROM USE NOW / MACHINE SHUTDOWN, then the other

thermostat has tripped at the same temperature. This is allowable

so long as the water temperature at the TPT9 was within the high

temperature limits range. See Table 1 for high temperature limits.

Verify the non-bypassed LED is lit. Record the temperature. Proceed

to step 12.

If the unit enters service mode 3 with no REMOVE FROM USE NOW

/ MACHINE SHUTDOWN alarm, then repeat steps 6 through 8 to

check the other thermostat

High Temperature Limits Fixed

(S2) & (S3)

44°C (111.2°F) to

49°C (120.2°F)

SERVICE MANUAL

Medi-Therm

®

III

26

j) High Temperature Backup Thermostat Trip Temperatures

[MT590 Test Tool Procedure, cont'd.]

12. Place both switches S2 and S3 in the bypass position. Turn the machine

off, then turn the machine on and select MANUAL mode. Allow machine

to run for approximately 1 minute. This will circulate cold water from

the reservoir past the thermostats, causing them to reset.

13. Return switches S2 and S3 to the normal position. If unit continues to

be in alarm condition, repeat step 12.

14. While the machine is running in MANUAL mode, place the RFU

CIRCUIT SELECT A-B switch in the “A” position and toggle the TEST

switch. The machine should shut down, blank the displays, light the

REMOVE FROM USE NOW / MACHINE SHUTDOWN LED, ash the

ALERT LED and toggle the audible alarm. Turn the machine off, then

restart the machine in the MANUAL mode.

Repeat the above procedure with the RFU CIRCUIT SELECT switch in

the “B” position.

This step will verify that both (redundant) RFU circuits are functioning.

15. Turnmachineoffandunplugthepowercord.Disconnect MT590

Test Tool from wire harness and reassemble machine.

Verify that the MT590 Test Tool or any installed shorting jumpers

have been removed before returning the machine to patient use.

Failuretodosomayresultindeathorseriousinjury.

7.3 FUNCTIONAL CHECK

AND SAFETY

INSPECTION

(continued)

FUNCTIONAL CHECK AND

SAFETY INSPECTION

SERVICE MANUAL

Medi-Therm

®

III

27

j) High Temperature Backup Thermostat Trip Temperatures

[Alternate Shorting Jumper Procedure]

To measure trip points of the high temperature backup thermostats if you

do not have access to an MT590 Test Tool, perform the following steps 1A-

20A. (If you have access to an MT590, follow steps 1-15 on the preceding

pages.)

• Changes to the wiring of the high temperature backup thermostats

can defeat their operation. To verify thermostat operation, perform

the Thermostat Verication Test described in section 7.3, item k, p. 29

after performing the following test procedure.

• After performing the following test procedure, verify that the MT590

Test Tool or any installed shorting jumpers have been removed