Part 46

Reference Guide

U.S. Department of Labor

Mine Safety and Health Administration

National Mine Health and Safety Academy

Other Training Materials

OT 54

February 2017

Visit the Mine Safety and Health Administration

Web site at www.msha.gov

T ABLEOFCONTENTS

INTRO DUCTION...............................................................................................................1

R

EGULATIONANDPOLICY.................................................................................................. 3

46.1...............................................................................................................................5

46.2...............................................................................................................................6

46.3.............................................................................................................................11

46.4.............................................................................................................................16

46.5.............................................................................................................................18

46.6.............................................................................................................................21

46.7.............................................................................................................................24

46.8.............................................................................................................................25

46.9.............................................................................................................................27

46.10...........................................................................................................................31

46.11...........................................................................................................................32

46.12...........................................................................................................................33

C

OMPLIANCEGUIDE(Q&A)............................................................................................ 35

TR AININGPLA N............................................................................................................ 71

S AMP LELESSONPLANS ..................................................................................................99

TR AININGRECORDS .....................................................................................................109

B LA NKFORMS/RECOR DS.........................................................................................111

S AMP LET RAININGRECORDS.................................................................................... 117

INTRODUCTION

This book was designed to assist mining operations who are regulated by MSHA’s

Part 46 regulations.This book provides regulations, policy, and frequently asked

questions and answers.It includes a blank training plan, sample l esson plans, and

trainingrec ords.

Intheregulationandpolicysection, informationfr omMSHA’sProgramPolicyManual

(PPM)hasbeenintegrated,soitcorrespondsdirectlywiththelistedregulation.Thi s

isfoll owedbytheComplianceGuidewhichisalistoffrequentlyaskedquestionsand

answers.

Whileteaching,youareexpectedtouseyourMSHAApprovedTrainingPlanasaguide.

Thetrainingplanisageneraloverviewofwhatandhowyouplantoteacheachprogram.

Itisrecommendedthatyoudevelopindividuallessonplansforeachsubject/courseyou

willbeteaching.Lessonplansaredetailedoutlinesindicatinghowyouplantoteachand

evaluateeachparticularsubjectwithinthetrainingprogram.

The sample lesson plans included in this book provide an example of things you may

teachforcertainsubjects.Theselessonplansarenotcomplete.Usetheseexamplesas

aguidetoaidyouindevelopingyoursite‐specificlessonplans.

As with the training plan, you can copy and use the blank training records that are

providedordevelopyourownwhichmustincludealltherequiredinformationlisted

inPart 46.9.Youwillalsofindexamplesofproperlycompletedtrainingrecords.

Remember,MSHA’sEducationalFieldandSm allMineServices(EFSMS)have training

specialistsavailabletoassistyou.Weencourageyoutocontactthemwhenyouhave

questions regarding training plans, training, or anything concerning Part 46

regulations.

1

REGULATION AND POLICY

Part 46

Part 46 regulates the training and retraining of miners engaged in shell dredging or

employed at sand, gravel, surface stone, surface clay, colloidal phosphate, surface

limestone, marble, granite, sandstone, slate, shale, traprock, kaolin, cement, feldspar,

and lime mines.

46.1 Scope

46.2 Definitions

46.3 Training Plans

46.4 Training Plan Implementation

46.5 New Miner Training

46.6 Newly Hired Experienced Miner Training

46.7 New Task Training

46.8 Annual Refresher Training

46.9 Records of Training

46.10 Compensation for Training

46.11 Site-Specific Hazard Awareness Training

46.12 Responsibility for Independent Contractor Training

3

30 CFR 46.1 - Scope.

The provisions of this Part set forth the mandatory requirements for training and

retraining miners and other persons at shell dredging, sand, gravel, surface stone,

surface clay, colloidal phosphate, and surface limestone mines.

PPM: General

Section 115 of the Federal Mine Safety and Health Act of 1977 (Mine Act)

and 30 CFR Part 46 require operators to have an approved training plan

under which miners are provided training. Part 46 training plans are

considered "approved" if they contain, at a minimum, the information

listed in § 46.3(b). Plans that do not contain the minimum information

listed in § 46.3(b) must be submitted to MSHA for approval.

Compliance Responsibility

Each mine operator is responsible for complying with all applicable

provisions of Part 46. Therefore, operators are required to provide all

required miner training.

Independent contractors working on mine property must comply with

the requirements of Part 46 (see "§ 46.12 Responsibility for Independent

Contractor Training"). This includes developing their own training plan

that meets the minimum requirements of Part 46 and providing

appropriate training.

Industries Affected by Part 46

Part 46 applies to miners working at surface shell dredging, sand, gravel,

surface stone, surface clay, colloidal phosphate, surface limestone,

marble, granite, sandstone, slate, shale, traprock, kaolin, cement,

feldspar, and lime mines.

Surface Areas of Underground Mines

Underground mines and their surface areas are covered by Part 48. The

Part 46 regulations do not apply to training for miners who work at

surface areas of underground mines. Miners who work in such areas

must continue to receive training that complies with the Part 48 training

regulations.

5

Government Officials on Part 46 Properties

Government officials visiting a mine site are not required to receive Part

46 training. However, MSHA expects those government agencies whose

personnel visit mine sites will ensure that their employees are provided

with appropriate personal protective equipment, and receive adequate

instruction and training. Where training is not provided, such

government officials should be accompanied by an experienced miner.

Satisfying both Part 46 and Part 48 requirements

MSHA will allow independent contractors who work at both Part 46 and

Part 48 surface mining operations to comply with the training

requirements of Part 48, instead of complying with both training rules.

This will eliminate the need for developing two training plans and

complying with two record-keeping requirements. These contractors

may choose to comply with the New Miner, Experienced Miner, Task, and

Annual Refresher Training programs of Part 48 to satisfy the training

requirements for both regulations. Independent contractors who choose

to follow this policy must have their own Part 48 training plan approved

by MSHA.

Part 46 defines construction workers who are exposed to hazards of

mining operations as miners. Independent contractors that perform

construction work on Part 46 properties may train under their own

approved Part 48 training plan to satisfy the Part 46 requirement for

training construction workers who are exposed to hazards of mining

operations.

Operators, at Part 46 operations, remain responsible for ensuring that

Site-specific Hazard Awareness Training (§ 46.11) is provided to these

contractors.

30 CFR 46.2 – Definitions.

The following definitions apply in this Part:

(a) Act means the Federal Mine Safety and Health Act of 1977.

(b) Competent person means a person designated by the production-operator or

independent contractor who has the ability, training, knowledge, or experience

to provide training to miners in his or her area of expertise. The competent

person must be able both to effectively communicate the training subject to

miners and to evaluate whether the training given to miners is effective.

6

PPM: "Competent Person" – Part 46 does not require that "competent

persons" be approved by MSHA. A "competent person," is a person who

is designated by the production-operator or independent contractor who

has the ability, training, knowledge, or experience to provide training to

miners in his or her area of expertise. The competent person must be

able to effectively communicate the training subject to miners, and

evaluate whether the training given to miners is effective.

A competent person may be credited for receiving any training they

provide toward their own training requirements.

(c) Equivalent experience means work experience where the person performed

duties similar to duties performed in mining operations at surface mines. Such

experience may include, but is not limited to, work as a heavy equipment

operator, truck driver, skilled craftsman, or plant operator.

PPM: "Equivalent Experience" is defined in Part 46 as work experience where

the person performed duties similar to duties performed in mining

operations at surface mines. "Equivalent experience" includes such

things as working at a construction site or other types of jobs where the

miner has duties similar to the duties at the mine. These duties could

include working as a heavy equipment operator, truck driver on a

highway construction site, skilled craftsman, or plant operator. To

determine equivalent experience, production-operators and independent

contractors must evaluate the work history of newly-hired employees in

determining whether the employees are "experienced" miners. This

determination is subject to review by MSHA as part of our verification

that production-operators and independent contractors have complied

with the training requirements of Part 46.

(d)(1) Experienced miner means:

(i) A person who is employed as a miner on April 14, 1999;

(ii) A person who has at least 12 months of cumulative surface mining or

equivalent experience on or before October 2, 2000;

(iii) A person who began employment as a miner after April 14, 1999, but

before October 2, 2000, and who has received new miner training

under Section 48.25 of this title or under proposed requirements

published April 14, 1999, which are available from the Office of

Standards, Regulations and Variances, MSHA, 201 12th Street South,

Arlington, VA 22202; or

(iv) A person employed as a miner on or after October 2, 2000, who has

completed 24 hours of new miner training under Section 46.5 of this

7

Part or under Section 48.25 of this title and who has at least 12

cumulative months of surface mining or equivalent experience.

PPM: Part 46 lists four ways to become an experienced miner.

1. Employed as a miner on April 14, 1999; or

2. Twelve months of cumulative surface mining or equivalent

experience on or before October 2, 2000; or

3. Began employment as a miner after April 14, 1999, but before

October 2, 2000, and who has received new miner training under §

48.25 or under the proposed requirements published April 14, 1999;

or

4. Employed as a miner on or after October 2, 2000, and completed 24

hours of new miner training under § 46.5 or under § 48.25 and has at

least 12 cumulative months of surface mining or equivalent

experience.

Once a miner has received new miner training under Part 46 or Part 48

and has accumulated 12 months of mining experience within 36 months

of receiving new miner training, MSHA considers that miner to be

experienced for life for training purposes at all Part 46 mines.

(d)(2) Once a miner is an experienced miner under this Section, the miner will retain

that status permanently.

(e) Independent contractor means any person, partnership, corporation, subsidiary

of a corporation, firm, association, or other organization that contracts to

perform services at a mine under this Part.

(f) Mine site means an area of the mine where mining operations occur.

(g)(1) Miner means:

(i) Any person, including any operator or supervisor, who works at a mine

and who is engaged in mining operations. This definition includes

independent contractors and employees of independent contractors

who are engaged in mining operations; and

(ii) Any construction worker who is exposed to hazards of mining

operations.

8

(g)(2) The definition of "miner" does not include scientific workers; delivery workers;

customers (including commercial over-the-road truck drivers); vendors; or

visitors. This definition also does not include maintenance or service workers

who do not work at a mine site for frequent or extended periods.

PPM: A miner is a person, including any operator or supervisor, who works at a

mine and who is engaged in mining operations. This definition includes

independent contractors and employees of independent contractors who

are engaged in mining operations; and construction workers who are

exposed to hazards of mining operations for frequent or extended

periods.

The definition of "miner" does not include scientific workers; delivery

workers; customers (including commercial over-the-road truck drivers);

vendors; or visitors.

Commercial over the road truck drivers are required to have Site-Specific

Hazard Awareness Training. Part 46 affords operators the discretion to

tailor Site-specific Hazard Awareness Training to the unique operations

and conditions at their mines. However, the training must in all cases be

sufficient to alert affected persons to site-specific hazards. Under Part

46, Hazard Awareness training is intended to be appropriate for the

individual who is receiving it and that the breadth and depth of training

vary depending on the skills, background, and job duties of the recipient.

This definition of "miner" also does not include maintenance or service

workers who do not work at a mine site for frequent or extended

periods.

"Frequent" exposure is defined as a pattern of exposure to hazards at

mining operations occurring intermittently and repeatedly over time.

"Extended" exposure means exposure to hazards at mining operations of

more than five consecutive work days.

(h) Mining operations means mine development, drilling, blasting, extraction,

milling, crushing, screening, or sizing of minerals at a mine; maintenance and

repair of mining equipment; and associated haulage of materials within the mine

from these activities.

PPM: Mining operations means mine development, drilling, blasting,

extraction, milling, crushing, screening, or sizing of minerals at a mine;

maintenance and repair of mining equipment; and associated haulage of

materials within the mine from these activities.

9

(i) New miner means a person who is beginning employment as a miner with a

production-operator or independent contractor and who is not an experienced

miner.

(j) Newly hired experienced miner means an experienced miner who is beginning

employment with a production-operator or independent contractor.

Experienced miners who move from one mine to another, such as drillers and

blasters, but who remain employed by the same production-operator or

independent contractor are not considered newly hired experienced miners.

(k) Normal working hours means a period of time during which a miner is otherwise

scheduled to work, including the sixth or seventh working day if such a work

schedule has been established for a sufficient period of time to be accepted as

the common practice of the production-operator or independent contractor, as

applicable.

PPM: For example, if miners on occasion work on Saturday, they can be trained

on Saturday. Part 46 also requires that miners who are being trained be

paid at a rate of pay they would have received had they been performing

their normal work tasks.

(l) Operator means any production-operator or any independent contractor whose

employees perform services at a mine.

(m) Production-operator means any owner, lessee, or other person who operates,

controls, or supervises a mine under this Part.

(n) Task means a work assignment or component of a job that requires specific job

knowledge or experience.

(o) We or us means the Mine Safety and Health Administration (MSHA).

(p) You means production-operators and independent contractors.

10

30 CFR 46.3 - Training Plans.

(a) You must develop and implement a written plan, approved by us under either

paragraph (b) or (c) of this Section that contains effective programs for training

new miners and newly hired experienced miners, training miners for new tasks,

annual refresher training, and site-specific hazard awareness training.

PPM: All mining operations which fall under Part 46 must develop and

implement a written training plan. Independent contractors who employ

"miners" are also primarily responsible for providing comprehensive

training to their employees. This requires independent contractors to

develop a training plan containing effective programs for providing this

training. If arrangements are made to receive training from the

production-operator, it must be indicated in the independent

contractor's training plan.

A training plan can be used for more than one mine. The plan must list

all mine names and MSHA mine identification numbers and must cover

all the appropriate training requirements, including Site-specific Hazard

Awareness Training, at each mine listed on the plan.

(b) A training plan is considered approved by us if it contains, at a minimum, the

following information:

(1) The name of the production-operator or independent contractor, mine

name(s), and MSHA mine identification number(s) or independent

contractor identification number(s);

PPM: MSHA does not require independent contractors to get an MSHA

identification number for purposes of Part 46.

However, if an independent contractor wants to obtain an MSHA

identification number:

please contact the local MSHA district office, or

to file online go to the MSHA Home Page (www.MSHA.gov) and

click on the tab titled "Forms & Online Filings."

11

(b)(2) The name and position of the person designated by you who is

responsible for the health and safety training at the mine. This person

may be the production-operator or independent contractor;

PPM: Some operators, particularly those that operate large facilities, may want

the flexibility of having more than one person who can certify that

training has been completed. These operators may list more than one

person as being responsible for training.

(b)(3) A general description of the teaching methods and the course materials

that are to be used in the training program, including the subject areas to

be covered and the approximate time or range of time to be spent on

each subject area.

PPM: "Approximate time" means the operator's reasonable estimate of the

amount of time that will be spent on a particular subject. For example,

the time listed for a particular subject may be "approximately 3 hours,"

recognizing that when the training is actually given it may require more

or less time than is indicated in the training plan. This flexibility allows

for adjustments based on changing mine conditions or operations,

including the needs and experience of the individuals who receive the

training.

When a range of time is used for each subject, the maximum times listed

for each subject must be equal to or exceed the required hours for new

miner (24) and annual refresher (8) training as required by the regulation.

When stating a range it cannot start with a zero.

Remember: In all cases a miner must receive no less than 24 hours of

new miner training and 8 hours of annual refresher training annually.

(b)(4) A list of the persons and/or organizations who will provide the training,

and the subject areas in which each person and/or organization is

competent to instruct; and

PPM: The training plan must include all "competent persons" who will

instruct in all subjects, including the name of the person who will

provide only one type of task training. It is acceptable to indicate

the names of several potential instructors for one subject or

course, where the operator may call on one of several competent

persons to provide the training. While it is acceptable to list the

organizations who will instruct on the training plan, the

certificates of training must list the specific competent person's

name who provides the training.

12

(b)(5) The evaluation procedures used to determine the effectiveness of

training.

PPM: Part 46 does not require a specific evaluation method. Instead

the rule allows you to select the method that will best determine

if training has been effective. Possible evaluation methods

include administering written or oral tests, or a demonstration by

the miner that he or she can perform all required duties or tasks

in a safe and healthful manner.

In addition, periodic work observations can be used to identify

areas where additional training may be needed and such

observations, along with feedback from the miners, could be used

to modify and enhance the training program.

(c) A plan that does not include the minimum information specified in paragraphs

(b)(1) through (b)(5) of this Section must be submitted to and approved by the

Regional Manager, Educational Field and Small Mines Services Division, or

designee, for the region in which the mine is located. You also may voluntarily

submit a plan for Regional Manager approval. You must notify miners or their

representatives when you submit a plan for Regional Manager approval. Within

two weeks of receipt or posting of the plan, miners and their representatives

may also request review and approval of the plan by the Regional Manager and

must notify the production-operator or independent contractor of such request.

(d) You must provide the miners' representative, if any, with a copy of the plan at

least 2 weeks before the plan is implemented or, if you request MSHA approval

of your plan, at least two weeks before you submit the plan to the Regional

Manager for approval. At mines where no miners' representative has been

designated, you must post a copy of the plan at the mine or provide a copy to

each miner at least 2 weeks before you implement the plan or submit it to the

Regional Manager for approval.

PPM: If the competent person listed in the approved training plan cannot

provide the training, and the training is scheduled within 2 weeks, the

operator may substitute an unlisted competent person for the listed

competent person without the 2 week advance notice, provided that the

operator informs all miners to be trained and their representatives prior

to substituting the competent person, and provided that no miners or

their representatives object to the substitution.

(e) Within 2 weeks following the receipt or posting of the training plan under

paragraph (d) of this Section, miners or their representatives may submit written

comments on the plan to you, or to the Regional Manager, as appropriate.

13

(f) The Regional Manager must notify you and miners or their representatives in

writing of the approval, or status of the approval, of the training plan within 30

calendar days of the date we received the training plan for approval, or within 30

calendar days of the date we received the request by a miner or miners'

representative that we approve your plan.

(g) You must provide the miners' representative, if any, with a copy of the approved

plan within one week after approval. At mines where no miners' representative

has been designated, you must post a copy of the plan at the mine or provide a

copy to each miner within one week after approval.

(h) If you, miners, or miners' representatives wish to appeal a decision of the

Regional Manager, you must send the appeal, in writing, to the Director for

Educational Policy and Development, MSHA, 201 12th Street South, Arlington,

VA 22202, within 30 calendar days after notification of the Regional Manager's

decision. The Director will issue a final decision of the Agency within 30 calendar

days after receipt of the appeal.

(i) You must make available at the mine a copy of the current training plan for

inspection by us and for examination by miners and their representatives. If the

training plan is not maintained at the mine, you must have the capability to

provide the plan within one business day upon request by us, miners, or their

representatives.

PPM: Availability of Training Plan

Section 46.3(i) requires a copy of the training plan to be produced within

one business day of a request by MSHA or the miners or their

representatives. The following example explains our policy for one

business day.

If MSHA requests that an operator produce a training plan for

examination on Tuesday at 1:00 p.m., the deadline for producing the plan

would be 1:00 p.m. on Wednesday. If MSHA requests that an operator

produce a plan at 2:00 p.m. on Friday at a mine that does not operate

over the weekend, the deadline for producing the plan would be 2:00

p.m. on Monday.

(j) You must comply with the procedures for plan approval under this Section

whenever the plan undergoes revisions.

PPM: If MSHA discovers that a plan does not meet the minimum requirements

of Part 46 one of two actions must be taken.

1) The operator can amend the plan to comply with the requirements of

Part 46.3(b) or

14

2) If you want to conduct training in accordance with the plan that does

not meet the minimum information specified in § 46.3(b), the plan

must be submitted and approved by the Regional Manager,

Educational Field and Small Mine Services Division, for the region in

which the mine is located. Until the plan is approved no training can

be conducted under the plan. Their addresses are:

Eastern Regional Manager

Educational Field and Small Mine Services (EFSMS)

National Mine Health and Safety Academy

1301 Airport Road

Beaver, WV 25813-9426

Telephone: (304) 256-3223

FAX: (304) 256-3319

E-mail: zzMSHA-EPD - EFSMS Beckley Region

Western Regional Manager

Educational Field and Small Mine Services (EFSMS)

P.O. Box 25367

Denver, CO 80225-0367

Telephone: (303) 231-5434

FAX: (304) 231-5474

E-mail: zzMSHA-EPD - EFSMS Denver Region

A plan may also be voluntarily submitted to one of the Regional

Managers for approval. MSHA has developed an online program to assist

in developing a Part 46 training plan. The following link will open up the

MSHA online advisor: http://webapps.dol.gov/elaws/msha_train.htm.

(k) The addresses for the EFSMS Regional Managers are as follows. Current

information on the EFSMS organization is available on MSHA's Internet Home

Page at http://www.msha.gov.

Eastern Regional Manager

Educational Field and Small Mine Services (EFSMS)

National Mine Health and Safety Academy

1301 Airport Road

Beaver, WV 25813-9426

Telephone: (304) 256-3223

FAX: (304) 256-3319

E-mail: zzMSHA-EPD - EFSMS Beckley Region

15

Western Regional Manager

Educational Field and Small Mine Services (EFSMS)

P.O. Box 25367

Denver, CO 80225-0367

Telephone: (303) 231-5434

FAX: (304) 231-5474

E-mail: zzMSHA-EPD - EFSMS Denver Region

30 CFR 46.4 - Training Plan Implementation.

(a) You must ensure that each program, course of instruction, or training session is:

(1) Conducted in accordance with the written training plan; (2) Presented by a

competent person; and (3) Presented in language understood by the miners who

are receiving the training.

PPM: "Presented in Language Understood by the Miners"

Training received by miners in Part 46 must be presented in a language

they understand. In addition, if warning signs at the mine serve as a

component of the Site-Specific Hazard Awareness Training, the signs

must be in a language or languages that are understood by the persons

who come onto the mine site.

If a competent person is providing training to a group, and some

individuals are not fluent in English, it is permissible to use a person who

is not a competent person as a translator. When using a translator, the

operator or contractor should ensure the translator has the ability to

translate the information accurately and completely. Further, the

translator should be familiar with the subject and terminology in the

language being translated, not just in English.

(b) You may conduct your own training programs or may arrange for training to be

conducted by: state or federal agencies; associations of production-operators or

independent contractors; miners' representatives; consultants; manufacturers'

representatives; private associations; educational institutions; or other training

providers.

(c) You may substitute, as applicable, health and safety training required by the

Occupational Safety and Health Administration (OSHA), or other federal or state

agencies to meet requirements under this Part. This training must be relevant to

training subjects required in this Part. You must document the training in

accordance with Section 46.9 of this Part.

16

(d) Training methods may consist of classroom instruction, instruction at the mine,

interactive computer-based instruction or other innovative training methods,

alternative training technologies, or any combination of training methods.

PPM: MSHA considers computer based or other interactive training

technologies to be training "methods," to be used by a competent person

effectively and appropriately. This would not necessarily require that the

competent person be in the room at all times; however, the competent

person must be available to evaluate the trainee's progress, and answer

questions as they arise.

(e) Employee health and safety meetings, including informal health and safety talks

and instruction, may be credited under this Part toward either new miner

training, newly hired experienced miner training, or annual refresher training

requirements, as appropriate, provided that you document each training session

in accordance with Section 46.9 of this Part. In recording the duration of

training, you must include only the portion of the session actually spent in

training.

30 CFR 46.5 - New Miner Training.

(a) Except as provided in paragraphs (f) and (g) of this Section, you must provide

each new miner with no less than 24 hours of training as prescribed by

paragraphs (b), (c), and (d). Miners who have not yet received the full 24 hours

of new miner training must work where an experienced miner can observe that

the new miner is performing his or her work in a safe and healthful manner.

PPM: A person who is beginning employment as a miner with a production-

operator or independent contractor and who is not an experienced miner

as defined in definitions under "Experienced Miner," is a new miner for

training purposes.

Close Observation

Section 46.5(e) requires that new miners be under the "close

observation" of a competent person when practicing as part of the health

and safety aspects of an assigned task. "Close observation" means that

the competent person must have the ability to observe a new miner's

work practices during task training ensuring the miner is not jeopardizing

his or her own health and safety or that of others. This does not mean

that the competent person must completely abandon his or her normal

duties, as long as the competent person can adequately monitor the

work practice. However, in some situations, the competent person may

17

have to cease normal work duties to ensure that this performance-based

standard is met.

If the training for a specific task is completed, the miner no longer needs

to be under the close observation of a competent person. However,

since the miner has not completed the 24 hours of "New Miner Training,"

the miner is required to work where an experienced miner can observe

his or her work practices until the 24 hours of training is completed.

A competent person may not be able in some instances to ride on a piece

of mobile equipment with the trainee. When available, the passenger

seat is the best location for a competent person providing training to a

miner in safe operation of the equipment. However, when a passenger

seat is not available, the competent person should be positioned in a safe

location in close proximity to the equipment being operated. The

competent person should closely observe and monitor the miner's

actions from that location.

(b) Before a new miner begins work at the mine -

You must provide the miner with no less than 4 hours of training in the following

subjects, which must also address site-specific hazards:

(1) An introduction to the work environment, including a visit and tour of the

mine, or portions of the mine that are representative of the entire mine

(walkaround training). The method of mining or operation utilized must be

explained and observed;

(2) Instruction on the recognition and avoidance of electrical hazards and

other hazards present at the mine, such as traffic patterns and control,

mobile equipment (e.g., haul trucks and front-end loaders), and loose or

unstable ground conditions;

(3) A review of the emergency medical procedures, escape and emergency

evacuation plans, in effect at the mine, and instruction on the firewarning

signals and firefighting procedures;

(4) Instruction on the health and safety aspects of the tasks to be assigned,

including the safe work procedures of such tasks, the mandatory health

and safety standards pertinent to such tasks, information about the

physical and health hazards of chemicals in the miner's work area, the

protective measures a miner can take against these hazards, and the

contents of the mine's HazCom program;

18

(5) Instruction on the statutory rights of miners and their representatives

under the Act;

(6) A review and description of the line of authority of supervisors and miners'

representatives and the responsibilities of such supervisors and miners'

representatives; and

(7) An introduction to your rules and procedures for reporting hazards.

(c) No later than 60 calendar days after a new miner begins work at the mine -

You must provide the miner with training in the following subject:

(1) Instruction and demonstration on the use, care, and maintenance of self-

rescue and respiratory devices, if used at the mine; and

(2) A review of first aid methods.

(d) No later than 90 calendar days after a new miner begins work at the mine -

You must provide the miner with the balance, if any, of the 24 hours of training

on any other subjects that promote occupational health and safety for miners at

the mine.

(e) Practice under the close observation of a competent person may be used to

fulfill the requirement for training on the health and safety aspects of an

assigned task in paragraph (b)(4) of this Section, if hazard recognition training

specific to the assigned task is given before the miner performs the task.

PPM: Hands-On Training

Hands-on training can be counted toward the training required for

miners under § 46.5 and § 46.6. Part 46 allows practice under the "close

observation of a competent person" to be used to fulfill the requirements

for training on the health and safety aspects of assigned tasks required

for new miners under § 46.5(b)(4) and newly hired experienced miners

under § 46.6(b)(4). The time spent in training may be used to fulfill the

training requirements as outlined in the training plan.

Location of Independent Contractor Training

Independent contractors with employees that are required to have 24

hours of new miner training under Part 46 are not required to provide

this training on the mine property where their employees will be

working. However, when an employee of an independent contractor

19

goes to a mine site, he or she must receive appropriate Site-specific

Hazard Awareness Training applicable to the miner's exposure to mine

hazards (remember, independent contractors who have received New

Miner Training, must also be current with their Annual Refresher Training

requirements before working on a mine property).

This Site-Specific Hazard Awareness Training could include site-specific

health and safety risks, such as geologic or environmental conditions,

recognition and avoidance of hazards such as electrical and powered

haulage hazards, traffic patterns and control, and restricted areas; and

warning and evacuation signals, evacuation and emergency procedures,

or other special safety procedures.

(f) A new miner who has less than 12 cumulative months of surface mining or

equivalent experience and has completed new miner training under this Section

or under Section 48.25 of this title within 36 months before beginning work at

the mine does not have to repeat new miner training. However, you must

provide the miner with training specified in paragraph (b) of this Section before

the miner begins work at the mine.

PPM: A miner who has less than 12 cumulative months of surface mining or

equivalent experience who has completed New Miner Training under

Part 46 or Part 48 Subpart B, within 36 months before beginning work at

a mine does not have to repeat new miner training (§ 46.5(f)). However,

this miner must receive 4 hours of training covering the 7 initial subjects

listed in § 46.5(b).

For example, a miner completes 24 hours of New Miner Training and

leaves the mine after working 6 months. The miner then begins work at

another mine 6 months later or 12 months since receiving New Miner

Training. Since the miner has not fulfilled the 12 months of mining or

equivalent experience and begins work at another mine within 36

months, the miner must receive 4 hours of training in the 7 initial

subjects listed in § 46.5(b) before going to work.

(g) A new miner training course completed under Section 48.5 or 48.25 of this title

may be used to satisfy the requirements of paragraphs (a), (b), and (c) of this

Section, if the course was completed by the miner within 36 months before

beginning work at the mine; and the course is relevant to the subjects specified

in paragraphs (b) and (c) of this Section.

20

30 CFR 46.6 - Newly Hired Experienced Miner Training.

(a) Except as provided in paragraph (f) of this Section, you must provide each newly

hired experienced miner with training as prescribed by paragraphs (b) and (c).

(b) Before a newly hired experienced miner begins work at the mine -

You must provide the miner with training in the following subjects, which must

also address site-specific hazards:

(1) An introduction to the work environment, including a visit and tour of the

mine, or portions of the mine that are representative of the entire mine

(walk around training). The method of mining or operation utilized must

be explained and observed;

(2) Instruction on the recognition and avoidance of electrical hazards and

other hazards present at the mine, such as traffic patterns and control,

mobile equipment (e.g., haul trucks and front-end loaders), and loose or

unstable ground conditions;

(3) A review of the emergency medical procedures, escape and emergency

evacuation plans, in effect at the mine, and instruction on the firewarning

signals and firefighting procedures;

(4) Instruction on the health and safety aspects of the tasks to be assigned,

including the safe work procedures of such tasks, the mandatory health

and safety standards pertinent to such tasks, information about the

physical and health hazards of chemicals in the miner's work area, the

protective measures a miner can take against these hazards, and the

contents of the mine's HazCom program;

(5) Instruction on the statutory rights of miners and their representatives

under the Act;

(6) A review and description of the line of authority of supervisors and miners'

representatives and the responsibilities of such supervisors and miners'

representatives; and

(7) An introduction to your rules and procedures for reporting hazards.

21

(c) No later than 60 calendar days after a newly hired experienced miner begins

work at the mine -

You must provide the miner with an instruction and demonstration on the use,

care, and maintenance of self-rescue and respiratory devices, if used at the

mine.

(d) Practice under the close observation of a competent person may be used to

fulfill the requirement for training on the health and safety aspects of an

assigned task in paragraph (b)(4) of this Section, if hazard recognition training

specific to the assigned task is given before the miner performs the task.

(e) In addition to subjects specified in paragraphs (b) and (c) of this Section, you may

provide training on any other subjects that promote occupational health and

safety for miners.

(f) You are not required to provide a newly hired experienced miner who returns to

the same mine, following an absence of 12 months or less, with the training

specified in paragraphs (b) and (c) of this Section. Instead you must provide such

miner with training on any changes at the mine that occurred during the miner's

absence that could adversely affect the miner's health or safety. This training

must be given before the miner begins work at the mine. If the miner missed

any part of annual refresher training under Section 46.8 of this Part during the

absence, you must provide the miner with the missed training no later than 90

calendar days after the miner begins work at the mine.

PPM: Part 46 does not specify a minimum length of time that must be devoted

to this training. The duration of the training needed by a newly hired

experienced miner depends on the occupational experience of the miner,

the work duties that the miner will perform, and the methods of mining

and workplace conditions at the mine where the miner will be working.

Except as explained below, the seven subjects listed in § 46.6(b) must be

covered before assigning the miner to work.

A newly hired experienced miner who returns to the same mine,

following an absence of 12 months or less, is not required to receive the

Experienced Miner Training under § 46(b) and (c). Instead the miner

must be provided with training on any changes at the mine that occurred

during the miner's absence that could adversely affect the miner's health

or safety. This training must be given before the miner begins work at

the mine. If the miner missed any part of annual refresher training under

§ 46.8 during the absence, the miner must be provided the missed

training no later than 90 calendar days after the returning miner begins

work at the mine.

22

There are no specific requirements for tracking, recording or verifying the

accumulation of experience. It is the operator's responsibility to

determine the miner's experience based on the miner's work and training

history.

When hiring a new experienced miner, Part 46 does not require any

specific proof of experience or documentation. However, a reasonable

effort should be made to justify previous experience. This may include

talking to previous employers, reviewing a resume, pay records, training

records, etc.

Experienced miners, who are current with their annual refresher training

and the appropriate task training and who move from one mine site to

another but remain employed by the same production-operator or

independent contractor, are required to receive Site-specific Hazard

Awareness Training at each mine where they work.

30 CFR 46.7 - New Task Training.

(a) You must provide any miner who is reassigned to a new task in which he or she

has no previous work experience with training in the health and safety aspects of

the task to be assigned, including the safe work procedures of such task,

information about the physical and health hazards of chemicals in the miner's

work area, the protective measures a miner can take against these hazards, and

the contents of the mine's HazCom program. This training must be provided

before the miner performs the new task.

(b) If a change occurs in a miner's assigned task that affects the health and safety

risks encountered by the miner, you must provide the miner with training under

paragraph (a) of this Section that addresses the change.

(c) You are not required to provide new task training under paragraphs (a) and (b) of

this Section to miners who have received training in a similar task or who have

previous work experience in the task, and who can demonstrate the necessary

skills to perform the task in a safe and healthful manner. To determine whether

task training under this Section is required, you must observe that the miner can

perform the task in a safe and healthful manner.

(d) Practice under the close observation of a competent person may be used to

fulfill the requirement for task training under this Section, if hazard recognition

training specific to the assigned task is given before the miner performs the task.

23

(e) Training provided under this Section may be credited toward new miner training,

as appropriate.

PPM: Part 46 does not specify the amount of time that must be spent on task

training. The performance-oriented approach of Part 46 allows for the

needs of individual miners to be taken into account when determining

the amount of time. A reasonable amount of time must be allotted for

training in each task, based on the individual needs of the miner and the

complexity of the assigned task.

If an experienced miner is trained on a specific piece of equipment and is

then assigned to operate a similar piece of equipment that is a different

model or made by a different manufacturer, that miner is required to

receive new task training on the new piece of equipment. Although there

may be similarities among different types of equipment, each type of

equipment has unique operational characteristics. Miners must be

trained on the unique characteristics of each piece of equipment that

they are assigned to operate.

Under Part 46 the written training plan must address each task for which

training will be conducted. The training plan must include a general

description of the teaching methods, course materials, evaluation

methods and competent person(s) who will conduct the training.

Additionally, the plan must list the approximate time or range of time to

be spent on each task training.

The time spent conducting each type of task training must be recorded

and listed on the certificate of training form. A "record" of task training

must be made at the completion of new task training. New task training

records must be "certified" at least once every 12 months or upon

request by the miner.

Task training can be a part of new miner training. Although it has a

slightly different name, new miners must receive instruction on the

health and safety aspects of the tasks to be assigned, including the safe

work procedures of such tasks, and the mandatory health and safety

standards pertinent to such tasks.

Hands-on training can be used to complete task training. The regulation

provides that; "practice under the close observation of a competent

person may be used to fulfill the requirement for task training." While

training under close observation may be done in a production mode,

emphasis should be placed on the training and not the production.

24

30 CFR 46.8 - Annual Refresher Training.

(a) You must provide each miner with no less than 8 hours of annual refresher

training—

(1) No later than 12 months after the miner begins work at the mine, or no

later than March 30, 2001, whichever is later; and

(2) Thereafter, no later than 12 months after the previous annual refresher

training was completed.

(b) The refresher training must include instruction on changes at the mine that

could adversely affect the miner's health or safety.

(c) Refresher training must also address other health and safety subjects that are

relevant to mining operations at the mine.

Recommended subjects include, but are not limited to: applicable health and

safety requirements, including mandatory health and safety standards;

information about the physical and health hazards of chemicals in the miner's

work area, the protective measures a miner can take against these hazards, and

the contents of the mine's HazCom program; transportation controls and

communication systems; escape and emergency evacuation plans, firewarning

and firefighting; ground conditions and control; traffic patterns and control;

working in areas of highwalls; water hazards, pits, and spoil banks; illumination

and night work; first aid; electrical hazards; prevention of accidents; health;

explosives; and respiratory devices.

Training is also recommended on the hazards associated with the equipment

that has accounted for the most fatalities and serious injuries at the mines

covered by this rule, including: mobile equipment (haulage and service trucks,

front-end loaders and tractors); conveyor systems; cranes; crushers; excavators;

and dredges.

Other recommended subjects include: maintenance and repair (use of hand

tools and welding equipment); material handling; fall prevention and protection;

and working around moving objects (machine guarding).

PPM: Section 46.8 requires that annual refresher training include instruction on

changes at the mine that could adversely affect the miners' health or

safety. In addition, refresher training must also address other health and

safety subjects that are relevant to mining operations at the mine.

Section 46.8 includes an extensive list of recommended subjects for

refresher training. The flexibility of the performance-based approach of

25

Part 46 allows production-operators and independent contractors to

determine the subjects to be covered in annual refresher training based

on the needs of their workforce and their operations.

In the regulation, the section on annual refresher training lists

recommended subjects that could be included in the training. It is not

acceptable to list all these subjects on the training plan and choose

different subjects from year-to-year. The training plan needs to

accurately represent each subject which you plan to cover during annual

refresher training.

As a reminder, if this list is modified, the miners' representative, if any,

must be provided with a copy of the plan at least 2 weeks before the plan

is implemented. If no miners' representative has been designated, post a

copy of the plan at the mine or provide a copy to each miner at least 2

weeks before the plan is implemented.

Annual Refresher Training Anniversary Dates

Annual refresher training anniversary dates are tracked monthly. For

example, if a miner completed annual refresher training some time in

February, the next annual refresher training must be completed by the

end of the following February.

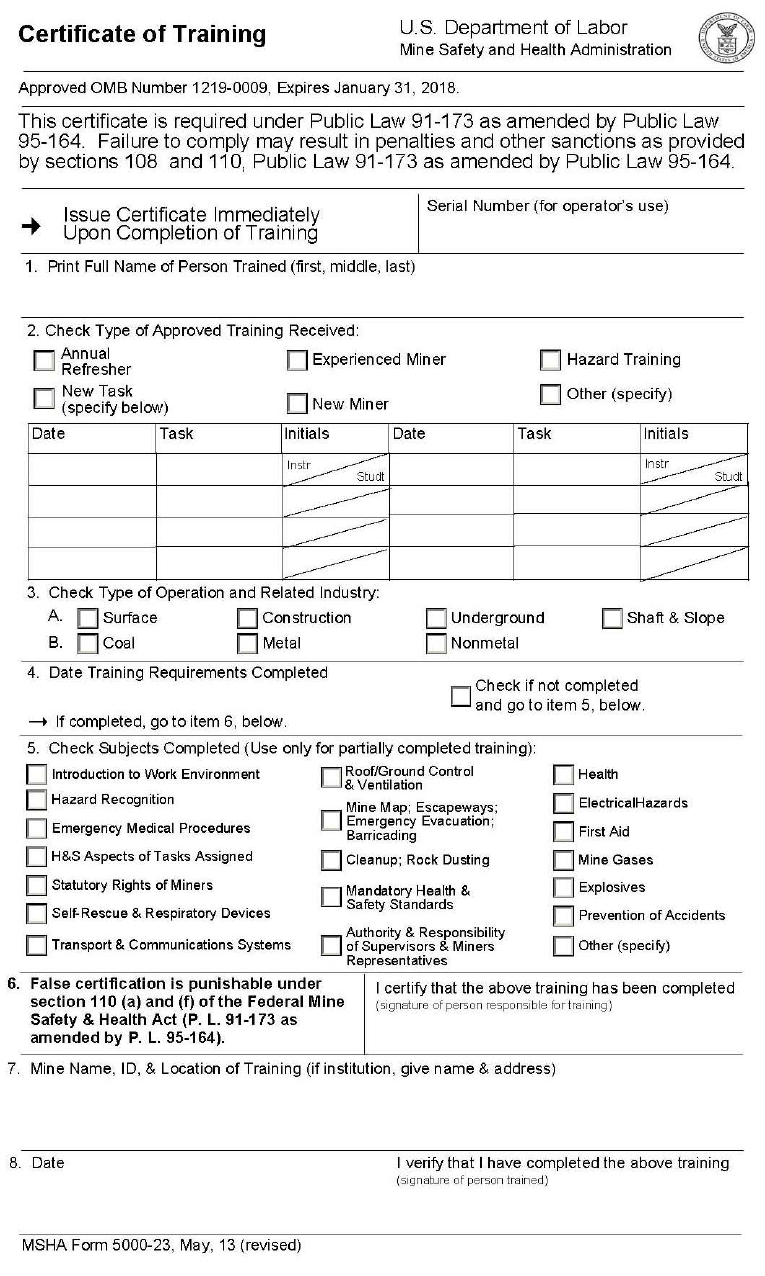

30 CFR 46.9 - Records of Training.

(a) You must record and certify on MSHA Form 5000-23, or on a form that contains

the information listed in paragraph (b) of this Section, that each miner has

received training required under this Part.

(b) The form must include:

(1) The printed full name of the person trained;

(2) The type of training, the duration of the training, the date the training was

received, the name of the competent person who provided the training:

(3) The name of the mine or independent contractor, MSHA mine

identification number or independent contractor identification number,

and location of training (if an institution, the name and address of the

institution).

26

(4) The statement, "False certification is punishable under Section 110(a) and

(f) of the Federal Mine Safety and Health Act," printed in bold letters and in

a conspicuous manner; and

(5) A statement signed by the person designated in the MSHA-approved

training plan for the mine as responsible for health and safety training that

states, "I certify that the above training has been completed."

(c) You must make a record of training under paragraphs (b)(1) through (b)(4) of this

Section.

(1) For new miner training under 30 CFR 46.5, no later than -

(i) when the miner begins work at the mine as required under Section

46.5(b);

(ii) 60 calendar days after the miner begins work at the mine as required

under Section 46.5(c); and

(iii) 90 calendar days after the miner begins work at the mine as required

under Section 46.5(d), if applicable.

(2) For newly hired experienced miner training under Section 46.6, no later

than -

(i) when the miner begins work at the mine; and

(ii) 60 calendar days after the miner begins work at the mine.

(3) Upon completion of new task training under Section 46.7;

(4) After each session of annual refresher training under Section 46.8; and

(5) Upon completion by miners of site-specific hazard awareness training

under Section 46.11.

(d) You must ensure that all records of training under paragraphs (c)(1) through

(c)(5) of this Section are certified under paragraph (b)(5) of this Section and a

copy provided to the miner -

(1) Upon completion of the 24 hours of new miner training;

(2) Upon completion of newly hired experienced miner training;

27

(3) At least once every 12 months for new task training, or upon request by

the miner, if applicable;

(4) Upon completion of the 8 hours of annual refresher training; and

(5) Upon completion by miners of site-specific hazard awareness training.

(e) False certification that training was completed is punishable under Section

110(a) and (f) of the Act.

(f) When a miner leaves your employ, you must provide each miner with a copy of

his or her training records and certificates upon request.

(g) You must make available at the mine a copy of each miner's training records and

certificates for inspection by us and for examination by miners and their

representatives. If training certificates are not maintained at the mine, you must

be able to provide the certificates upon request by us, miners, or their

representatives.

PPM: Making Records Available to MSHA

A copy of each miner's training records and certificates must be made

available for inspection by MSHA and for examination by miners and their

representatives. This includes both certified training records and records

that have not yet been certified.

(h) You must maintain copies of training certificates and training records for each

currently employed miner during his or her employment, except records and

certificates of annual refresher training under Section 46.8, which you must

maintain for only two years. You must maintain copies of training certificates

and training records for at least 60 calendar days after a miner terminates

employment.

PPM: Maintaining Training Plans and Records

Operators and contractors must make available for inspection by MSHA

and by miners and their representatives training plans, training records

and certificates (§ 46.9 (g)). If the training plan, training records or

certificates are not physically kept at the mine site, they must be

"produced upon request;" such as by having them sent from another

location via fax machine or computer. Training plans must be made

available within one business day, but training records, and certificates

with the signature of the person responsible for health and safety

training must be made available before inspection activity at the mine

concludes for the day. The reason for the difference is a matter of

28

urgency. If a miner is untrained or improperly trained, it is a hazard to

the miner and to other miners.

Training records and certificates must be made available to the inspector

at the mine site. The inspector may choose, as a matter of convenience,

to inspect the records at the office or location where the records are

maintained or have them faxed to an MSHA office for his or her

inspection that day.

(i) You are not required to make records under this Section of site-specific hazard

awareness training you provide under Section 46.11 of this Part to persons who

are not miners under Section 46.2. However, you must be able to provide

evidence to us, upon request, that the training was provided, such as the training

materials that are used; copies of written information distributed to persons

upon their arrival at the mine; or visitor log books that indicate that training has

been provided.

PPM: Part 46 requires that operators record and certify the training that miners

receive. Recording means creating a written record of the training. The

record must include:

The full name of the person trained;

The type of training;

Duration of training;

The date the training was received;

The name of the competent person who provided the training;

Name of mine or independent contractor;

MSHA mine identification or independent contractor number (if

applicable); and

Location of training (if an institution, the name and address of

institution).

Certifying means verifying, by signature, that the training listed on the

written record was completed as indicated on the form. Part 46 requires

that this certification be done by the person who has been designated by

the operator as responsible for health and safety training at the mine and

whose name appears on the training plan. Certifying is required at the

completion of training, such as at the end of the 24 hours of new miner

training.

Training records must be certified at:

The completion of new miner training;

The completion of newly hired experienced miner training;

29

The completion of the 8 hours of annual refresher training;

Least once every 12 months for new task training or upon request by

the miner; and

The completion of Site-specific Hazard Awareness Training for miners.

A training record or certificate may be maintained in any format,

provided that it contains information listed in § 46.9(b). A "Certificate of

Training Form" (MSHA Form 5000-23) may also be used.

If an MSHA Form 5000-23 is used, it must list the competent instructor(s)

who conducted the training, the duration of the training and that the

training is for Part 46.

MSHA has developed a sample form which can be used. Both the sample

form and the MSHA Form 5000-23 are available from MSHA's Internet

Home Page (www.msha.gov), from MSHA's Educational Field and Small

Mine Services, or from MSHA District and Field offices.

Under § 46.9(b), the records of training must include the name of the

competent person who provided the training. If more than one

competent person provided the training, the names of all persons must

be included.

It is acceptable to list more than one miner on a record or certificate of

training. Part 46 allows operators flexibility in choosing the appropriate

form for records of training, provided that the form used includes the

minimum information specified in § 46.9(b)(1) through (b)(5).

The person who has been designated by the operator or independent

contractor as responsible for health and safety training is required to

certify, by signature, that training has been completed. This should not

be confused with the "competent person" who conducts the training.

For example, a state, vocational school or cooperative instructor listed in

a training plan may conduct the training and be recorded as the

competent person for each subject they teach. The person, who is

designated as the person responsible for Part 46 as indicated on the

training plan, must certify that the training was completed.

Training Certificates for People who are not Considered Miners

A record of training is not required for Site-specific Hazard Awareness

Training for persons who are not miners under § 46.2. However,

operators must be able to provide evidence to us, upon request, that the

training, when applicable, was provided. This evidence may include the

30

training materials used, including appropriate warning signs, written

information distributed to persons, or a visitor log book that reflects that

Site-specific Hazard Awareness Training has been given.

30 CFR 46.10 - Compensation for Training.

(a) Training must be conducted during normal working hours. Persons required to

receive training must be paid at a rate of pay that corresponds to the rate of pay

they would have received had they been performing their normal work tasks.

(b) If training is given at a location other than the normal place of work, persons

required to receive such training must be compensated for the additional costs,

including mileage, meals, and lodging, they may incur in attending such training

sessions.

PPM: Training under Part 46 must be conducted during normal working hours,

and the miner must receive the same rate of pay he or she would have

received if performing normal tasks at that time. For example, if a miner

is paid at time and a half for working on Saturday, the miner must be paid

at that same rate for receiving training on Saturday.

30 CFR 46.11 - Site-Specific Hazard Awareness Training.

(a) You must provide site-specific hazard awareness training before any person

specified under this Section is exposed to mine hazards.

(b) You must provide site-specific hazard awareness training, as appropriate, to any

person who is not a miner as defined by Section 46.2 of this Part but is present at

a mine site, including:

(1) Office or staff personnel;

(2) Scientific workers;

(3) Delivery workers;

(4) Customers, including commercial over-the-road truck drivers;

(5) Construction workers or employees of independent contractors who are

not miners under Section 46.2 of this Part;

31

(6) Maintenance or service workers who do not work at the mine site for

frequent or extended periods; and

(7) Vendors or visitors.

(c) You must provide miners, such as drillers or blasters, who move from one mine

to another mine while remaining employed by the same production-operator or

independent contractor with site-specific hazard awareness training for each

mine.

(d) Site-specific hazard awareness training is information or instructions on the

hazards a person could be exposed to while at the mine, as well as applicable

emergency procedures. The training must address site-specific health and safety

risks, such as unique geologic or environmental conditions, recognition and

avoidance of hazards such as electrical and powered-haulage hazards, traffic

patterns and control, and restricted areas; and warning and evacuation signals,

evacuation and emergency procedures, or other special safety procedures.

(e) You may provide site-specific hazard awareness training through the use of

written hazard warnings, oral instruction, signs and posted warnings, walk

around training, or other appropriate means that alert persons to site-specific

hazards at the mine.

(f) Site-specific hazard awareness training is not required for any person who is

accompanied at all times by an experienced miner who is familiar with hazards

specific to the mine site.

PPM: Part 46 provides that Site-specific hazard awareness training may be

provided through the use of written hazard warnings, oral instruction,

signs and posted warnings, walkaround training, or other appropriate

means that alert affected persons to site-specific hazards at the mine.

Part 46 allows the flexibility to tailor hazard awareness training to the

specific conditions and practices at the mine. In many cases, an effective

Site-specific Hazard Awareness Training program will include a

combination of different types of training. The training must be sufficient

to alert affected persons to site-specific hazards.

Site-specific Hazard Awareness Training is not required for any person

who is accompanied at all times by an experienced miner who is familiar

with hazards specific to the mine site.

32

30 CFR 46.12 - Responsibility for Independent Contractor Training.

(a)(1) Each production-operator has primary responsibility for ensuring that site-

specific hazard awareness training is given to employees of independent

contractors who are required to receive such training under Section 46.11 of

this Part.

(a)(2) Each production-operator must provide information to each independent

contractor who employs a person at the mine on site-specific mine hazards

and the obligation of the contractor to comply with our regulations, including

the requirements of this Part.

(b)(1) Each independent contractor who employs a miner, as defined in Section

46.2, at the mine has primary responsibility for complying with Section 46.3

through 46.10 of this Part, including providing new miner training, newly

hired experienced miner training, new task training, and annual refresher

training.

(b)(2) The independent contractor must inform the production-operator of any

hazards of which the contractor is aware that may be created by the

performance of the contractor's work at the mine.

PPM: Section 46.12(a)(1) establishes that the production-operator has primary

responsibility for ensuring that Site-specific Hazard Awareness Training is

given to employees of independent contractors, while § 46.12(b)(1)

establishes that each independent contractor who employs a miner

under this Part has primary responsibility for complying with other

required training. MSHA views § 46.12 as a regulatory indication of

whom the agency will cite for training violations under ordinary

circumstances. Both the production-operator and the independent

contractor share the responsibility that all miners receive all required

training, and in extraordinary circumstances, MSHA may determine that

both the production-operator and the independent contractor should be

held liable for training violations.

Even though the production-operator has primary responsibility for

ensuring that Site-specific Hazard Awareness Training is provided, there

may be times where it is more practical for the independent contractor

to provide the training. Production-operators may provide independent

contractors with site-specific hazard awareness information or training

materials and arrange for the independent contractors to provide the

training to the contractors' employees. Where this arrangement is made,

the production-operator must list the independent contractor by name

and document in their training plan that the independent contractor

33

identified will be providing Site-specific Hazard Awareness Training. Even

under this arrangement, the production-operator is still responsible for

ensuring that the appropriate training is provided.

Independent Contractor Training Records

Independent contractors who are miners as defined by Part 46, must

make available at the mine site where they are working, a copy of each

miner's training certificate for inspection.

34

Part 46 COMPLIANCE GUIDE

Version 3 - Published May 28, 2001

Training and Retraining of Miners Engaged in Shell Dredging or Employed at Sand,

Gravel, Surface Stone, Surface Clay, Colloidal Phosphate, or Surface Limestone Mines.

We (MSHA) developed this compliance guide to provide information to the surface

nonmetal mining community about the new Part 46 training regulations. This is the

second edition of this Compliance Guide. We have added additional questions and

answers based on questions we have received since the release of the first guide.

We also wrote this guide in the more personal style advocated by the President’s

executive order on “Plain Language.” In this guide “you” refers to the mine operator

and independent contractor, and “we” and “us” refer to MSHA.

Part 46 is a performance-oriented rule and many of the requirements allow you to

decide how and when your training will be conducted, select the topics appropriate for

your mining operations, and choose the instructor(s). With a performance-oriented

rule, like Part 46, there is more than one way to meet its requirements, and the way you

comply may differ from another mining operation.

Although we believe that Part 46 is clearly written and easy to understand, we

developed this compliance guide to answer typical questions about the rule. As we

continue to work with mine operators and miners, we will learn from our experience

and share this information with you through updates to this guide. We recognize that

the safety and health hazards associated with mining are site-specific and mine

operators need flexibility to achieve the new regulation’s objectives. Part 46 was

written with this in mind.

Please contact your local MSHA office if you have any questions about the applicability

of Part 46 requirements at your operation.

The compliance guide was published in 2001. For clarification purposes, additional

information has been provided in green text.

35

General Section

1. Are other commodities not listed in the title to this regulation covered under

Part46?

Yes. Part 46 also covers surface mining operations at the following commodities:

marble, granite, sandstone, slate, shale, traprock, kaolin, cement, feldspar, and

lime.

2. Which training regulations apply — Part 48 or Part 46 — to miners who are

employed in the surface area of an underground mine, e.g., the surface area of

an underground limestone mine?

Surface areas of underground mines are and have been covered by Part 48. The

Part 46 regulations therefore do not apply to training for miners who work in

those areas. Miners who work in such areas must continue to receive training that

complies with the Part 48 training regulations.

3. Are state and federal personnel who visit a mine covered by the Part 46 training

requirements?

No. Government officials visiting a mine site are not required to receive Part 46

training. However, we expect those government agencies whose personnel visit

mine sites will ensure that their employees are provided with appropriate personal

protective equipment, and receive adequate instruction and training. Where

training is not provided, such government officials should be accompanied by an

experienced miner.

4. When will MSHA begin to enforce the provisions of the Part 46 training rules?

The Part 46 training rules become effective October 2, 2000, and will then be

subject to enforcement.

5. Do I have any responsibilities or obligations under Part 46 training rules between

October 1999 and October 2, 2000?

The regulations will become effective on October 2, 2000. At that time, you must

have a training plan developed and in place. In addition, beginning at that time,

you must: train any new miners who have never worked at a mining operation

before, and make sure that your “experienced” miners are on schedule to receive

their annual refresher training, and make sure all miners are experienced based on

one of the criteria listed in the regulation for becoming an experienced miner, and

make sure all people requiring site-specific hazard training are receiving this

training.

37

6. Are there any “key” dates in the rule that I should know about?

The key dates to keep in mind are October 2, 2000, when you must have a training

plan in place, that is being implemented, and March 30, 2001, when all of your

experienced miners, who were employed before March 30, 2000, must receive

annual refresher training (unless you’ve been providing annual refresher training

all along, in which case you may continue using the 12 month schedule already

established).

7. If a crusher that typically operates at mines that fall under the Part 46

regulations is moved onto a mine site where Part 48 regulations apply, what set

of regulations would apply?

If the crusher is being operated at a mine site where the Part 48 regulations apply,

the workers who operate the crusher are required to receive Part 48 training.

MSHA’s Educational Policy and Development group has anticipated such an

overlap between Parts 46 and 48 and are available to assist with training plans to

minimize any unnecessary redundancy in complying with both training rules.

8. What type of training is required for commercial over-the-road truck drivers,

including customers who drive onto mine property and have their trucks loaded,

and then deliver their load off the mine property?

Commercial over-the-road truck drivers are required to have Site-Specific Hazard

Awareness training. Part 46 affords operators the discretion to tailor site-specific

hazard awareness training to the unique operations and conditions at their mines.

However, the training must in all cases be sufficient to alert affected persons to

site-specific hazards. We intend that hazard awareness training be appropriate for

the individual who is receiving it and that the breadth and depth of training vary

depending on the skills, background, and job duties of the recipient.