NanoQuant Plate™

Quick Guide

2 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 2013-06

Table of Contents

1. General Information ...................................................................... 3

1.1 Introduction ....................................................................... 3

1.2 Contents of the NanoQuant Plate Package.................... 3

1.3 Computer Requirements .................................................. 4

1.4 System Requirements ...................................................... 5

1.5 Applications ...................................................................... 6

2. Measurement Procedure............................................................... 7

2.1 Software Installation Procedure ...................................... 7

2.2 Performing a Measurement ............................................. 7

2.3 File menu ......................................................................... 15

2.4 Quality Control of NanoQuant Plate ............................. 17

3. NanoQuant Plate .......................................................................... 19

3.1 Parameters ...................................................................... 19

3.2 Handling and Cleaning ................................................... 21

3.3 Applying Samples ........................................................... 22

3.4 NanoQuant Plate Disinfection ....................................... 23

4. Calculations ................................................................................. 25

4.1 Calculation of Nucleic Acid Concentration .................. 25

5. About the Quick Guide ................................................................ 29

2013-06 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 3

1. General Information

1.1 Introduction

Tecan’s NanoQuant Plate is intended as a general laboratory measurement

tool for the quantification of small volumes (2μl) of nucleic acids in absorbance

mode and the measurement of the labeling efficiency of nucleic acids labeled

with fluorescent dyes. The NanoQuant Plate permits the application and

parallel measurement of 16 different samples in a single measurement

procedure. After the measurement, which is controlled by Tecan’s i-control

software, the calculation of nucleic acid content and purity check using the

260/280 ratio is performed automatically and the results are displayed in an

Excel sheet. A blanking measurement, including an integrated reference

wavelength at the beginning of the measurement procedure, functions

simultaneously as a quality control check for the entire plate and indicates any

pipetting or cleaning mistakes. The plate has been designed to meet the

requirements of research laboratories working with various types of low-volume

samples including fluorophore-labeled nucleotides.

1.2 Contents of the NanoQuant Plate Package

The NanoQuant Plate package for Infinite reader series contains the following

items:

• NanoQuant Plate

• Pipetting Aid

• Safety Certificate

• This Quick Guide

• Storage Box

The NanoQuant Plate is available for the following readers:

• Infinite M200 PRO

• Infinite F200 PRO

• Infinite M200 PRO NanoQuant

• Infinite F200 PRO NanoQuant

• Infinite M1000

• Infinite F500

4 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 2013-06

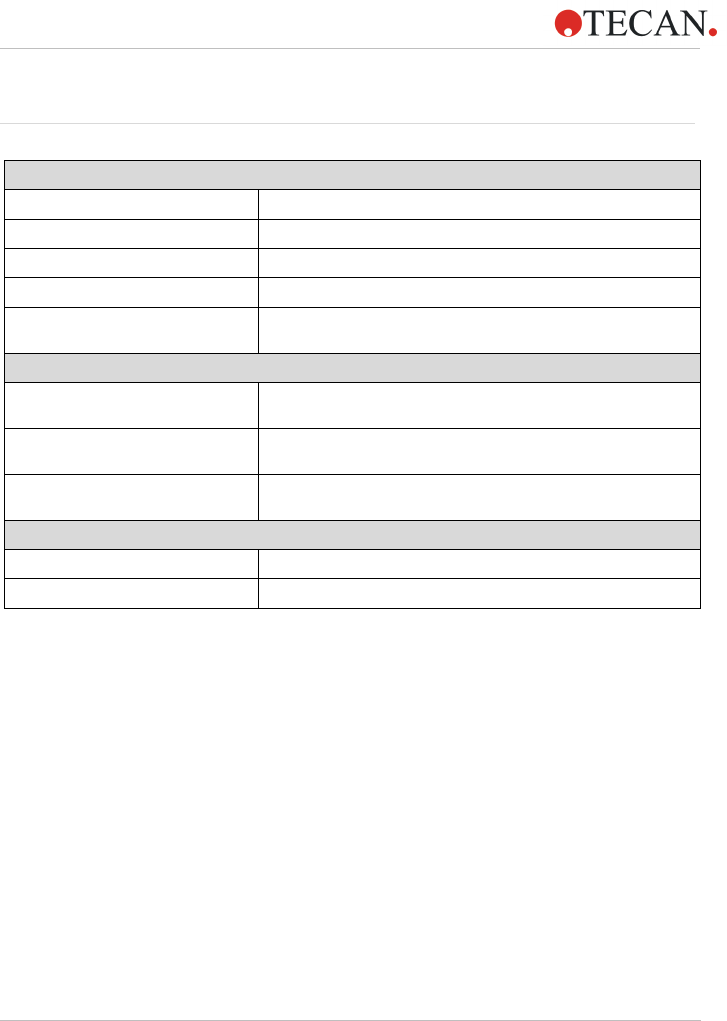

1.3 Computer Requirements

The following computer requirements are needed to use the i-control software:

Minimum Recommended

PC

Windows XP/Vista (32 bit)/Windows 7 (32 or 64 bit)

Windows compatible PC with a Pentium compatible

processor running at 1 GHz

2 GHz

(Dual Core)

Operating

System

Windows XP (32-bit) SP3

Windows Vista (32-bit)

Windows 7 (32-bit)

Windows 7 (64-bit)

Windows XP

(32-bit) SP3

Memory

Windows XP: 512 MB RAM

Windows Vista (32-bit): 1 GB RAM

Windows 7 (32-bit): 1 GB RAM

Windows 7 (64-bit): 2 GB RAM

1 GB RAM

2 GB RAM

2 GB RAM

3 GB RAM

Space

Requirements

700 MB 1 GB

Monitor Super VGA Graphics

Resolution 1024 x 768 1280 x 1024

Color Depth 256

Mouse Microsoft mouse or compatible pointing device

Communication 1 x USB 2.0

2 x USB 2.0,

1 x RS232

(Serial)

Devices

1 x CD-ROM drive

Windows Vista: DirectX 9 graphics and 32 MB of

graphics memory (for Home Basic); 128 MB of

graphics memory plus WDDM support for all other

versions

Windows 7: DirectX 9 graphics device with WDDM 1.0

or higher driver

.NET

Microsoft .NET Framework 2.0

If this version is not present, the install/upgrade

program will install it side-by-side with any existing

installations of the .NET Framework.

Windows

Installer

3.1

If this version is not present, the install/upgrade

program will install it.

Microsoft Excel

2002, 2003, 2007, 2010 (32-bit) – Starter edition NOT

supported!

2013-06 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 5

1.4 System Requirements

To perform a NanoQuant measurement, the following items are required:

Infinite 200 Pro

• An Infinite 200 Pro reader with firmware version V2.0 or higher

• A computer with i-control V1.4 Service Pack 1 or higher installed

• The NanoQuant Plate Package

Make sure the following absorbance filters are available on the filter slide of

your Infinite F200 PRO:

• Position 1: 260 nm (5 nm bandwidth)

• Position 2: 280 nm (3 nm bandwidth)

• Position 3: 340 nm (10 nm bandwidth)

• Position 4: free (for individual use)

For Infinite F200 PRO, the filter positions must remain in the order in which they

were delivered. The original filter positions guarantee the fastest filter switching

for well-wise measurements. The Infinite M200 PRO can be used immediately

for measurement without any calibration of the monochromator.

Infinite M1000, Infinite F500

• An Infinite M1000 reader (REF 30061442) with main firmware version

V2.0 or higher

• An Infinite F500

• Software: i-control V1.8 or higher

• The NanoQuant Plate Package

Make sure the following absorbance filters are available on the filter slide of

your Infinite F500:

• Position 1: 260 nm (5 nm bandwidth)

• Position 2: 280 nm (3 nm bandwidth)

• Position 3: 340 nm (10 nm bandwidth)

Note

Only use the Infinite reader and the NanoQuant Plate at room temperature and

under normal laboratory conditions.

6 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 2013-06

1.5 Applications

Nucleic Acid Quantification (Infinite 200 PRO, Infinite M1000,

Infinite F500)

For the quantification procedure in the NanoQuant Plate, a sample volume of

2 μl is sufficient for accurate results. Absorbance of nucleic acid samples is

measured at 260 nm. The optical path length of the NanoQuant Plate is

0.5 mm. To assess the purity of the nucleic acid, an additional measurement at

280 nm is performed to indicate proteins in the sample. For pure nucleic acids,

a 260/280 ratio between 1.8 - 1.9 is acceptable. If this ratio is lower than 1.8 it

may indicate the presence of proteins or other contaminants. If this is the case,

an additional purification step/procedure is recommended.

Labeling Efficiency (Infinite M200 PRO and Infinite M1000 only)

Working with nucleic acids labeled with fluorescent dyes requires samples of

high quality. Besides common nucleic acid quantification and nucleic acid purity

check with 260/280, the labeling efficiency is an important criterion for improved

research results. With the NanoQuant Plate it is possible to measure

absorbance of nucleic acids labeled with Cy3, Cy5, Alexa 555, Alexa 647 and

many other fluorescent dyes.

Note

All measurements on Infinite M1000 involving NanoQuant Applications are

performed using one measurement channel only.

2013-06 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 7

2. Measurement Procedure

2.1 Software Installation Procedure

The i-control software is installed using the following procedure:

1. Insert the i-control software CD ROM into your CD ROM drive.

2. A window opens with different selectable options.

3. Choose Software and install i-control.

4. Follow the instructions of the Wise Installation Wizard.

5. When installation is successful, exit the Installation window.

6. Switch on and connect to Infinite instrument.

Note

i-control is delivered with the Infinite reader series.

2.2 Performing a Measurement

For applications using the NanoQuant Plate, a tab called Applications is

implemented in i-control software, so that all measurements can be

performed quickly and easily.

1. Start i-control.

2. Connect to the Infinite instrument. The standard i-control window

opens.

3. Select Applications in the lower left part of the window.

Figure 1: Overview of i-control script

8 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 2013-06

4. Select the desired measurement type in the control bar on the left side

of the window by double-clicking or dragging and dropping:

• Nucleic acid quantification (Infinite 200 PRO, Infinite M1000,

Infinite F500)

• Labeling Efficiency (Infinite M200 PRO and Infinite M1000 only)

5. The corresponding measurement stripe appears and the NanoQuant

Plate definition file (NanoQuant Plate Tecan 16 Flat Black) is

automatically selected in the Plate field.

6. Select blanking mode. Select the Individual Blanking check box for

individual blanking or leave the check box clear for average blanking.

See Individual Blanking and Average Blanking on page 12.

7. Depending on the connected instrument, the wavelengths used for

measurement are selected automatically (make sure that the correct

filters are properly installed and defined on the filter slides of the

Infinite F200 PRO and Infinite F500 instrument).

Instrument Bandwidth at 260 nm Bandwidth at 280 nm

Infinite M200 PRO: 5 nm 5 nm

Infinite F200 PRO: 5 nm 3 nm

Infinite M1000: 5 nm 5 nm

Infinite F500: 5 nm 3 nm

8. Select a sample type (e.g. dsDNA, ssDNA, RNA, etc. in the Sample

type drop-down list.

9. In addition, select the respective dye(s) in the Markers drop-down lists

for Labeling Efficiency measurements. If the samples are labeled with

only one fluorophore, set the drop-down list of Dye 2 to None.

10. When all settings are correct, click the Start Blanking button to

initialize the blanking measurement. The plate transport moves out

and the user is requested to insert the NanoQuant Plate with the

respective blanking buffer.

2013-06 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 9

Figure 2: Correct orientation of NanoQuant Plate in the reader

11. The first measurement step is blanking with the required buffer. A

separate window opens and the blanking procedure can be observed.

12. The blanking measurement is started and can be monitored in the

measurement progress window. If blanking has been performed

successfully, the sample positions are highlighted in yellow and the

screen color changes to a homogenous green (Nucleic Acid

Quantification) or blue (Labeling Efficiency). Blanking results (date and

time, samples positions that were selected for blanking, blanking

range, and maximum CV) are displayed next to the plate preview in

the measurement stripe and saved until the instrument is

disconnected.

13. When the blanking measurement has been completed successfully,

the plate is moved out automatically. The plate is now ready for

sample application and analysis. The green Start button is now

accessible.

14. Remove any remaining blanking buffer from the sample positions by

wiping the quartz spots with a piece of lint free paper and apply 2 μl of

the samples onto each spot.

15. When the NQP is loaded with samples and correctly placed onto the

plate carrier, click the green Start button.

10 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 2013-06

16. As the measurement is performed an Excel sheet opens automatically

in the background. All measurement results (including the

automatically calculated nucleic acid concentration, the 260/280 ratio,

and for Labeling Efficiency measurements, the dye concentration) are

concisely displayed in a matrix (analogous to the plate layout). The

OD values of each sample at all relevant wavelengths are also

displayed.

Figure 3: Overview of Excel result sheet

17. Once the measurement procedure is finished, the plate is moved out

automatically. A pop-up message appears, asking if the user wishes

to perform another measurement.

• If additional (identical) measurements are to be performed, wipe

o any sample residues from the previous measurement and

apply new samples. Click

Yes to start the measurement.

• If no further measurement is to be performed, click No. An extra

sheet appears in the Excel workbook summarizing the results of

all previous measurements.

2013-06 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 11

Figure 4: Automatic summary in Excel of all measured samples

18. When all measurements are completed, clean the NanoQuant Plate

thoroughly and store it appropriately.

19. Once i-control has been closed, the Infinite reader can be switched

off.

Note

Excel workbooks containing the measurement results are not saved

automatically. This has to be done by the user. It is possible to save the

method script created in i-control for further use by clicking Save in the File

menu.

12 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 2013-06

Additional blanking information

The blanking information will be stored until:

• The reader is disconnected

• The i-control is shut down

• Another sample type is selected

If other sample types are selected, the screen color will become a light

green or light blue gradient again depending on the application and the

blanking procedure must be repeated with corresponding wavelengths.

If you have chosen a labeling efficiency measurement before starting a

blanking procedure, the type of samples and the specific wavelengths for

dyes have to be selected. If the correct fluorophores are selected, the

samples can be applied into the NanoQuant Plate.

Individual Blanking and Average Blanking

The user may choose between two distinct blanking options: Average

Blanking and Individual Blanking (set by default). For Average Blanking,

choose which wells are to be used for blanking by dragging a frame around

the respective sample positions in the plate preview. It is generally

recommended to perform the blanking measurement with all 16 sample

positions, however average blanking must be done with at least two wells,

in order to calculate an average value that is used to blank-correct all

measured samples.

The OD results measured with average blanking have to be below 10% CV

in order to grant reliable measurement results.

Figure 5: Click Start Blanking button for Average Blanking

2013-06 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 13

In contrast, Individual Blanking requires blanking on all wells that are to be

used for subsequent measurements. Individual blanking information is

stored for each well used and blank-correction of the samples is done with

the corresponding single blanking value (of the same well) instead of one

average blank.

Figure 6: Select Individual Blanking and click the Start Blanking button to start

individual blanking

It is recommended to use Individual Blanking as the standard blanking

option in order to obtain the most precise and reliable results.

Figure 7: Individual Blanking information in the Excel result sheet

Note

The CV value displayed in the Last Blanking box (see Figure 11) represents

the variation coefficient of all wells used for blanking.

14 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 2013-06

Sample ID function

The Sample ID function allows the user to individually name each

sample/well. By clicking the Sample ID box, a window opens and the user

may enter the desired sample names. By clicking the Clear button, all

inserted Sample IDs are deleted. Sample IDs are displayed in the summary

sheet. Click Save to store the entries and click Close to complete the

procedure.

Sample IDs may also be copied from Excel sheets and pasted into sample

ID list.

“Show Raw Data”

To view all measurement results as raw values, the NanoQuant tab in the

Results Presentation dialog box contains the Show Raw Data check box.

2013-06 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 15

By checking this box, the results summary sheet will include raw OD values

at all measured wavelengths as well as blank- and reference wavelength-

corrected OD values and the automatically calculated sample

concentrations and ratio values.

Figure 8: Raw Data Output in the Excel results summary

(1) Nucleic acid quantification

(2) Labeling efficiency

2.3 File menu

i-control Toolbar

Start a measurement

Connect or disconnect an instrument

Move plate out

Move plate in

Show or hide the info pane

Open the i-control help file.

Sample

The following sample types can be selected:

• dsDNA

• ssDNA

• RNA

• Others

16 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 2013-06

Upon selecting Others, the Edit Samples window opens. The star marks a

free line where additional sample types can be entered with the

corresponding standard coefficient [µg/ml] for 1 cm path length at 260 nm.

A ratio wavelength of 230 nm or 280 nm can also be selected from the

drop-down menu.

Figure 9: Selecting and adding new samples

Note

For the Infinite F200 PRO and Infinite F500, the correct filters must always

be used and defined correctly in the filter slide. If a wavelength is selected

that is not available (because the filter is not in the slide) an error message

appears.

Figure 10: Editing or creating new markers

Note

The selected sample in Edit Sample must always have the ratio wavelength

set at 280 nm, otherwise no marker can be selected for Dye 1 or Dye 2 and

an error message appears.

2013-06 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 17

2.4 Quality Control of NanoQuant Plate

Average Blanking Out of Range (CV ≥ 10 %)

If Average Blanking is out of range, the failed wells are highlighted in pink

and an error message appears requesting the user to repeat blanking

measurement.

In this case, single wells are displayed in pink, indicating these wells as

diverging after blanking. These wells differ from the calculated CV by 10 %,

meaning that these quartz wells are dirty due to lint, fingerprints, etc.

Figure 11: Color code for blanking: pink wells are out of range

18 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 2013-06

There are two possibilities to complete the blanking procedure:

1. Repeat blanking with the same plate and select white wells

(e.g. E1 – G2 in the example below) by dragging a frame around

them. The newly selected wells will appear white, the diverging wells

change from pink to purple and all other wells turn blue to indicate that

they are unused.

Figure 12: Color code for blanking procedure when re-selected: purple wells indicate

formerly pink wells

2. Move the plate out, repeat the cleaning procedure and apply fresh

blanking samples into the plate and start blanking again.

2013-06 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 19

3. NanoQuant Plate

3.1 Parameters

Physical

Optics 16 quartz lenses (one per sample)

Quartz lens Optical path length: 0.5 mm diameter: 2.2 mm

Parallel measurement 16 sample positions (2 rows of 8)

Sample volume Min. 2 μl

Dimensions plate

Plate width: 85.4 mm Plate height: 14.6 mm Plate length:

127.8 mm Weight: ~ 160 g

Wavelength settings

Infinite M200 PRO

260 nm (5 nm bandwidth), 280 nm (5 nm bandwidth),

310 nm (5 nm bandwidth) reference

Infinite M1000

260 nm (5 nm bandwidth), 280 nm (5 nm bandwidth),

310 nm (5 nm bandwidth) reference

Infinite F200 PRO, Infinite F500

260 nm (5 nm bandwidth), 280 nm (3 nm bandwidth),

340 nm (10 nm bandwidth) reference

Measurement time of whole plate

Quantify Nucleic Acid Infinite 200 PRO: 1.15 minute for 16 samples

Labeling Efficiency Infinite 200 PRO: 2 minutes for 16 samples

20 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 2013-06

Typical performance values Infinite 200 PRO

Wavelength absorbance

Wavelength accuracy < ± 0.5 nm for λ > 315 nm

< ± 0.3 nm for λ ≤ 315 nm

Wavelength reproducibility < ± 0.5 nm for λ > 315 nm

< ± 0.3 nm for λ ≤ 315 nm

Absorbance bandwidth Infinite M200 PRO < 5 nm for λ ≤ 315 nm

< 9 nm for λ > 315 nm

Absorbance bandwidth Infinite F200 PRO Depending on filters used

Measurement absorbance

Detection limit (DNA concentration) 1 ng/μl dsDNA

Reproducibility of one sample (50 μg/ml) < 1 % CV

Ratio 260/280 (50 μg/ml) ± 0.07

Precision @ 260 nm < 0.2 %

Accuracy @ 260 nm < 0.5 %

Figure 13: Technical drawing of the NanoQuant Plate (dimensions in mm)

2013-06 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 21

3.2 Handling and Cleaning

In achieving optimal measurement results, the cleaning of the NanoQuant

Plate is one of the most essential parts of the entire measurement

procedure. There are two procedures for cleaning the NanoQuant Plate:

Cleaning Procedure with Ultrasonic Bath

1. Fill an ultrasonic bath with water and place a suitable beaker filled with

distilled water into the ultrasonic bath.

2. Switch on the ultrasonic and immerse the lid of the NanoQuant Plate

into the beaker, with bobbing movements for about 20 seconds. Take

care not to immerse the hinge of the plate.

3. Repeat the procedure with the bottom part of the NanoQuant Plate.

4. Remove any surplus water from the NanoQuant Plate with dry and oil-

free compressed air.

Cleaning Procedure with Kimwipe

1. Moisten a laboratory Kimwipe with 70% ethanol and clean the inner

and outer surfaces of the NanoQuant Plate.

2. Moisten a piece of cotton or Kimwipe with distilled water and clean

both sides of each quartz lens on the NanoQuant Plate.

3. Wipe off any excess liquid with a dry Kimwipe.

After cleaning, store the plate in a dirt-free and lint-free place. No lint, nor

any kind of dirt or streaks, should be on the quartz lenses. Any

contamination can lead to false measurements. When measuring many

different samples one after the other, the quartz wells can be cleaned with a

(wet) Kimwipe. The cleaning and maintenance procedures are important in

order to prolong the NanoQuant Plate’s lifespan and to reduce the need for

servicing. It is recommended to store the cleaned NanoQuant Plate in the

aluminum storage box.

Note

Lint, dirt or fingerprints on the quartz lenses may alter the OD values

significantly! Avoid getting dirt on the spacers as well as this can lead to a

change of the highly precise gap between the lid of the NanoQuant Plate

and thus alter the OD values. Apply samples only onto clean quartz lenses!

22 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 2013-06

3.3 Applying Samples

There are two different ways to apply samples on the plate:

Multi Channel Pipette

The fastest way to apply 16 samples onto the plate is by using an 8 fold

multi channel pipette. Always use optimal tips for the multi channel pipette

to ensure precise and consistent application of the samples.

Figure 14: Applying samples onto the NanoQuant Plate

If you need help applying the samples precisely into the wells with a multi

channel pipette, use our pipetting aid: Place the pipetting aid with the

indentation downward onto the quartz wells. The pipetting aid must be

secured on the steel pins.

Figure 15: NanoQuant Plate with pipetting aid

Apply the samples into the wells. Carefully remove the pipetting aid

upwards without touching the sample drops. Immediately close the lid and

put the plate into the reader.

2013-06 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 23

Single Pipette

Optionally, you can use a single pipette, but pay attention to the following:

• To increase precision and to avoid cross contamination with other

samples, always use a new tip.

• Work in a timely manner – otherwise the samples may quickly

evaporate, leading to false results

• Close the lid carefully and put the plate into the reader.

Note

Always start and connect instrument before applying samples onto the

plate. Work in timely manner when applying samples onto the plate to avoid

evaporation of samples! Only use NanoQuant Plate at room temperature.

Significant variations in temperature can lead to changes in the optical path

length and therefore to imprecise OD values!

3.4 NanoQuant Plate Disinfection

All parts of the NanoQuant Plate that come in contact with patient samples,

positive control samples or hazardous material must be treated as

potentially infectious areas. Spray or apply 70% ethanol, which is

commonly used for laboratory cleaning, over the whole plate. After an

exposure time of 5 minutes dry the NanoQuant Plate with a lint-free

Kimwipe.

Safety Certificate

To ensure safety and health for Tecan service personnel, our customers

are kindly asked to complete the Safety Certificate (enclosed in the

envelope) and sign it by a qualified person before shipping. For shipment,

please attach one copy of the completed sheet to the package in which the

NanoQuant Plate is returned and the other copy to the shipping documents.

If a Safety Certificate is not supplied, the instrument may not be accepted

by the servicing center.

2013-06 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 25

4. Calculations

To correct the OD values due to dirt on the outer surfaces of the quartz

lenses, an additional measurement at a reference wavelength is performed

automatically with each measurement. For Infinite M200 PRO and

Infinite M1000 readers, a reference wavelength of 310 nm is used

and for the Infinite F200 PRO and Infinite F500 readers, a reference

wavelength of 340 nm is used.

4.1 Calculation of Nucleic Acid Concentration

After the absorbance measurements of the nucleic acids have been

performed in the NanoQuant Plate, i-control and Excel automatically

calculate the nucleic acid concentration according to the Lambert-Beer law,

including the reference values.

A = ε * d * c

A Absorbance

ε Molarity Extinction Coefficient (L mol

-1

cm

-1

)

d Distance (path length in cm)

c Concentration (mol L

-1

)

Calculation of DNA concentration:

DNA purity is automatically performed in the background as described in

the following: Generally, in analytical chemistry the absorbance A is defined

as

A

λ

= log

10

[OD]

where

I is the intensity of light at a specified wavelength that has passed through

a sample (transmitted light intensity) and

I

0

is the intensity of the light before it enters the sample.

Absorbance measurements are often carried out in analytical chemistry,

since the absorbance of a sample is proportional to the thickness of the

sample and the concentration of the absorbing species in the sample.

Absorbance is a logarithmic dimension; its unit is OD (Optical Density).

26 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 2013-06

Example

An absorbance value of 1 OD means a transmittance of 10%, and an

absorbance value of 2 OD means a transmittance of 1%, etc. Because

absorbance calculations are based on logarithmic dimensions, calculations

between absorbance sample values and absorbance blank values are

performed by subtraction and not by division. For more information review

the Lambert-Beer law.

4.2 Blanks

Average Blanking

The average absorbance value at 310 nm for Infinite M200 PRO and

Infinite M1000 (340 nm for Infinite F200 PRO and Infinite F500) of all wells

used for blanking is subtracted from the average absorbance value at

260 nm or 280 nm. The relative variation of the wells used for average

blanking must be below 10% in order to be able to start a measurement.

Infinite M200 PRO and Infinite M1000

Abs

blank average

= Abs

260 average

– Abs

310 average

[OD]

Infinite F200 PRO and Infinite F500

Abs

blank average

= Abs

260 average

– Abs

340 average

[OD]

Individual Blanking

The well-specific absorbance value at 310 nm for Infinite M200 PRO and

Infinite M1000 (340 nm for Infinite F200 PRO and Infinite F500) is

subtracted from the corresponding absorbance value at 260 nm.

Infinite M200 PRO/Infinite M1000

Abs

blank A1

= Abs

260 A1

– Abs

310 A1

[OD]

Abs

blank A2

= Abs

260 A2

– Abs

310 A2

[OD]

Abs

blank B1

= Abs

260 B1

– Abs

310 B1

[OD]

etc.

2013-06 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 27

Infinite F200 PRO/Infinite F500

Abs

blank A1

= Abs

260 A1

– Abs

340 A1

[OD]

Abs

blank A2

= Abs

260 A2

– Abs

340 A2

[OD]

Abs

blank B1

= Abs

260 B1

– Abs

340 B1

[OD]

etc.

Individual blanking information is stored for each well used and blank-

correction of the samples is done with the corresponding single blanking

values instead of one average blank. Every well that is to be used for

sample measurement needs to be blanked beforehand.

4.3 Samples

Calculations based on Average Blanking

The well-specific absorbance value at 310 nm for Infinite M200 PRO and

Infinite M1000 (340 nm for Infinite F200 PRO and Infinite F500) is

subtracted from the corresponding absorbance value at 260 nm. Each well

used for sample measurement is then blanked with the average blanking

value.

Infinite M200 PRO/Infinite M1000

Abs

A1

= (Abs

260 A1

– Abs

310 A1

) – Abs

blank average

[OD]

Abs

A2

= (Abs

260 A2

– Abs

310 A2

) – Abs

blank average

[OD]

Abs

B1

= (Abs

260 B1

– Abs

310 B1

) – Abs

blank average

[OD]

etc.

Infinite F200 PRO/Infinite F500

Abs

A1

= (Abs

260 A1

– Abs

340 A1

) – Abs

blank average

[OD]

Abs

A2

= (Abs

260 A2

– Abs

340 A2

) – Abs

blank average

[OD]

Abs

B1

= (Abs

260 B1

– Abs

340 B1

) – Abs

blank average

[OD]

etc.

28 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 2013-06

Calculations based on Individual Blanking

The well-specific absorbance value at 310 nm for Infinite M200 PRO and

Infinite M1000 (340 nm for Infinite F200 PRO and Infinite F500) is

subtracted from the corresponding absorbance value at 260 nm. Each well

used for sample measurement is then blanked individually with the

corresponding blanking value.

Infinite M200 PRO/Infinite M1000

Abs

A1

= (Abs

260 A1

– Abs

310 A1

) – Abs

blank average

[OD]

Abs

A2

= (Abs

260 A2

– Abs

310 A2

) – Abs

blank average

[OD]

Abs

B1

= (Abs

260 B1

– Abs

310 B1

) – Abs

blank average

[OD]

etc.

Infinite F200 PRO/Infinite F500

Abs

A1

= (Abs

260 A1

– Abs

340 A1

) – Abs

blank average

[OD]

Abs

A2

= (Abs

260 A2

– Abs

340 A2

) – Abs

blank average

[OD]

Abs

B1

= (Abs

260 B1

– Abs

340 B1

) – Abs

blank average

[OD]

etc.

The absorbance values at 280 nm are also corrected by the corresponding

absorbance values at 310 nm for Infinite M200 PRO and Infinite M1000

(or 340 nm for Infinite F200 PRO and Infinite F500). The corrected

absorbance values are used for the 260/280 ratio calculation.

2013-06 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 29

5. About the Quick Guide

This document describes the NanoQuant Plate, which has been designed

as a general laboratory measurement tool to quantify small volumes (2 μl)

of Nucleic Acids in absorbance mode and additionally to measure labeling

efficiency of nucleic acids labeled with fluorescent dyes.

This document instructs how to:

• Perform measurement procedures using a NanoQuant Plate

• Clean and maintain the NanoQuant Plate

Note

Every effort has been made to avoid errors in text and diagrams; however,

Tecan Austria GmbH assumes no responsibility for any errors that may

appear in this publication. It is the policy of Tecan Austria GmbH to improve

products as new techniques and components become available. Tecan

Austria GmbH therefore reserves the right to change specifications at any

time with appropriate verification, validation, and approvals. We would

appreciate any comments on this publication.

Manufacturer

Tecan Austria GmbH

Untersbergstrasse 1A

A-5082 Grödig/Salzburg

Austria/Europe

T +43 6246 8933 444

F +43 6246 8933 6444

www.tecan.com

30 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 2013-06

Trademarks

The following product names and any registered or unregistered

trademarks mentioned in this document are used for identification purposes

only and remain the exclusive property of their respective owners:

• NanoQuant Plate™, Infinite

®

, i-Control™, Tecan

®

and the Tecan Logo

are registered trademarks of Tecan Group Ltd., Männedorf,

Switzerland

• Kimwipe

®

is a registered trademark of Kimberly-Clark Corporation,

Irving, TX, USA

• Pentium

®

is a registered trademark of Intel Corporation, Santa Clara,

CA, USA

• Windows

®

and Excel

®

are registered trademarks of Microsoft

®

Corporation, Redmond, WA, USA

Copyright Information

The contents of this document are the property of Tecan Austria GmbH and

are not to be copied, reproduced, or transferred to another person or

persons without prior written permission.

Copyright © 2013, Tecan Austria GmbH

All rights reserved. Printed in Austria

2013-06 Quick Guide NanoQuant Plate

TM

No.30035094 Rev No. 1.4 31

Warnings, Cautions and Notes

The following types of notices are used in this publication to highlight

important information or to warn the user of a potentially dangerous

situation:

Note: Gives helpful information.

Caution: Indicates a possibility of product damage or data loss if

instructions are not followed.

Warning: Carefully read and follow the instructions provided in this

document before using the software or using the product.

Symbols

Manufactured by