CAUTION

This gar

age door has been designed to be as as easy as possible to use, service and automate when installed

correctly. Please therefore take time to read these instructions fully before beginning any work. Note: This door has

been designed to hang on a 70mm x 70mm timber goalpost fr

ame (not supplied).

IMPORTANT INFORMATION

1 This garage door is intended for domestic use only.

2 Garage doors are heavy and may have sharp edges.

Wear protective gloves. Installation should not be undertaken

alone.Care must be taken when handling.

3 Ensure the door is continuously supported before it is secured

and avoid installing in windy conditions.

4 Do not attempt to install or adjust this door if you are unsure of

any of the instructions below.

BEFORE COMMENCING WORK

Remove all wrapping

Before starting: remove all wrapping and check door has been supplied with correct

lifting gear kit. Kit code is on identification label on reverse of door.

Check opening size

Before fitting door, check opening size and squareness of timber frame. The door is made

smaller to give correct clearance within the frame.

Check headroom

There must be a minimum of 42mm headroom above lower face of top timber or lintel.

This must reach back into the garage for at least 1875mm.

Check the “goalpost” frame

The “goalpost” timber frame should be a minimum of 70mm x 70mm square (2

3

/

4

” x 2

3

/

4

”),

in good condition and securely fixed to the surrounding structure.

Tools

All the initial fitting work is done from inside the garage, so all tools and parts should be to

hand there before door is placed in opening.

1

2

3

4

5

You will need:

• 6mm & 10 mm flat bladed screwdriver • Tape measure

• No 2 & 3 posi-drive screwdriver • hammer

• Drill and 2.5mm drill bit (for pilot holes) • Grease

• 13mm A/F socket/spanner • Engineer’s pliers

• 10mm A/F socket/spanner • 19mm x 19mm timber weatherbead to fit under

• 7mm A/F socket/spanner the head of the door frame

• Protective gloves • 70mm x 70mm timber goal post frame

•

Shar

p knif

e

•

W

edges (pac

king pieces)

Note to installer: Please ensure that this instruction sheet remains with the door for the owner’s future reference.

ISSUE B MAY 2005 DPIN 045112

•

DOOR IS HEAVY TO OPEN:

Cause: Spring tension set too low

Solution: Re-set spring tension as detailed on the door maintenance label.

•

DOOR OPENS TOO QUICKLY:

Causes: Spring tension set too high.

Solution: Re-set spring tension as detailed on the door maintenance label.

•

DOOR DOES NOT DELATCH:

Cause: Latch cables may have been set too long.

Solution: If you are not locked out of the garage at the time, then the cables should be set to allow nominal

6mm latch engagement with the latch plates. If you are locked out of the garage, call your installer/supplier

for assistance.

•

DOOR HANDLE FAILS TO TURN:

Probable Cause: A jammed lock barrel.

Solution: Unfortunately this can only be remedied by a service call, however, this is not usually chargeable

during the warranty period. Please contact your supplier for details.

•

KEY FAILS TO TURN IN LOCK:

Probable Cause: Door handle has not been turned to the fully closed position.

Solution: Return the handle to the fully closed (horizontal) position and try again. If the problem still persists,

contact your supplier.

•

LOST KEYS:

Solution:

Contact your supplier. The lock barrel will need to be replaced, but the method for doing this will

vary. If you can get into your garage, the problem can be easily solved by removing the handle assembly

from the door and replacing the lock barrel with a new one. If you are locked out, contact your supplier.

THESE INSTRUCTIONS MUST BE FOLLOWED CAREFULLY

GARAGE DOORS ARE HEAVY AND AWKWARD TO HANDLE. ENSURE

ASSISTANCE IS AVAILABLE AND THAT SAFETY GLOVES ARE WORN.

1. Fix all latches in the fully retracted position.

2. Open door and safely prop in the open position.

3. Remove springs from their hangers. (wear eye protection).

4. With assistance remove prop and close door slowly until fully closed.

5. Prop door in fully closed position and place packers beneath the door between

base of door and floor.

6. Remove all track supports and remove track fixing screws from the frame and

remove.

7. Remove fixings to main pivot brackets, door should now rest on packers.

8. Remove bottom door mounting brackets.

9. Remove main pivot blocks.

10. The door can now be carefully removed from the opening. Seek assistance

in lifting.

11. If door is to be disposed of please do so in a responsible manner in line with the

latest legislation applicable at the time.

Slideaway

Double & Heavy Double Door Gear

INSTALLATION INSTRUCTIONS

11

Slideaway

Single & Maximizer Door Gear

TROUBLE SHOOTING

POWER OPERATION

UPON COMPLETION

2

Fix lower side seals into position using five 1” clout nails

per side.

Check door operation to ensure door opens and closes

satisfactorily.

Check that lock and latches operate correctly.

Ensure all fixings are securely tightened

Fit 19mm

× 19mm timber weatherbead to the underside of

the top timber lintel (Fig K).

Do not paint the spring or any moving parts.

Lubricate all moving parts/pivot points (refer to

maintenance label for details) lubrication is an essential

ongoing requirement to ensure the continuing smooth

operation of your door.

Ask your professional Garage Door Specialist about

remote controlled electric operators.

Lintel

Door

19mm

× 19mm

Weatherbead

1

2

3

4

5

6

7

8

K

DISMANTLING INSTRUCTIONS

In the event of difficulty please contact your local Garage Door Specialist or call our

Gara

g

e Door Helpline.

See main CE label for details

This door is suitable for power operation. In order to conform with current legislation

only independantly tested and certified operators may be fitted. A list of approved

operators is contained on the Declaration of Incorporation supplied with your door.

Align holes in latch plates with holes in lo

wer side

seals. Drill pilot holes and secure each plate using two

no.12 x 1

1

/2” self tapping screws. Cut away flexible

lower side seals locally where latch strikes the latch

plate

Fit each wheel bracket to top corner plate of door

using four no.12 x 3/4" self tapping screws ensuring

two vertical slots in wheel bracket are facing down-

wards as shown (Figure E). Slide tracks over wheels

and press firmly up and out in the direction of arrow

until tracks are horizontal. Drill pilot holes in side jambs

and secure each track fixing bracket using two no 12 x

1

1

/2” self tapping screws and two M8 washers, ensur-

ing wheel is in contact with the bottom of the track.

Slide track hangers over ends in orientation

shown in main assembly diagram Slide to a

convenient roof joist

within 200 mm (8”) from end of

track and fix each hanger to joist using ONE no.12 x

1

1

/2” self tapping screw only at this stage. For best

results ensure tracks are hanging horizontally, square

to the frame and parallel to each other At this stage the

tracks should be able to swing sideways.

Slide track end bungs into position in orientation

shown (see Fig. F). Secure each end bung to track

using two off M6 x 30mm hexagon head bolts and two

M6 nyloc nuts ensuring nuts locate firmly into

hexagonal recess in end bung

1 FITTING YOUR DOOR

CAUTION ! Please ensure all tools and parts are inside the garage before the door is

placed in the opening.

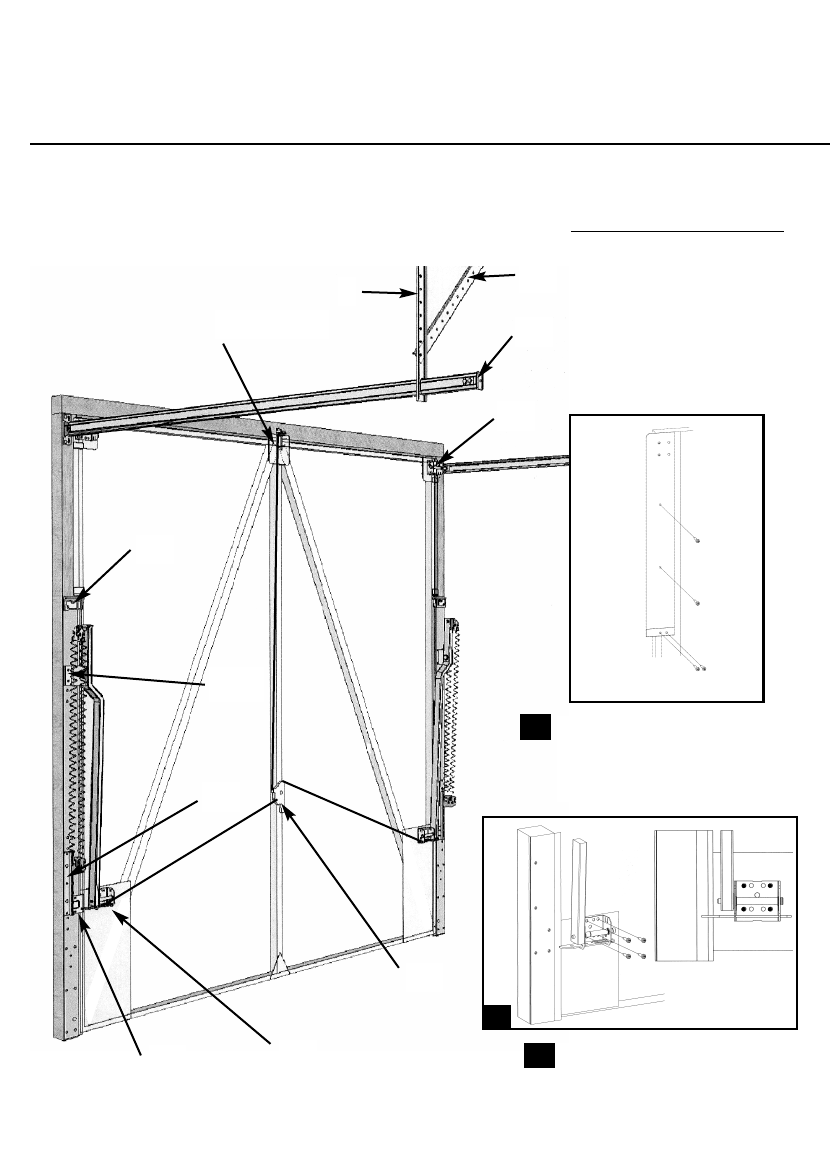

Assembly diagram (maximizer door gear illustrated)

Numbers refer to installation notes

Swing the pivot arms up, align two holes in

each lo

wer side seal with those in main pivot

br

ackets. Ensure lip on lower side seal locates

against side of jamb f

or full length of side seal.

NO

TE: for special sized doors the bottom of

side seal must be cut short to suit installation.

Drill pilot holes and secure each main pivot

bracket using two M8 x 50mm coach screws

and two M8 washers per side. (See Fig B)

Smooth lower side seals into position. Align

pivot blocks with holes in lower side seals as

shown. (Fig. C) drill pilot holes and secure

using two no.12 x 1

1

/2”: self tapping screws

per block.

1

2

3

4

5

6 11

16

12

Fully open door and prop securely in position.

With the door still open the tr

acks should be parallel

This can be chec

ked by ensuring both roller wheels are

in contact with the tr

ack end bungs. Bolt track braces to

hangers using one M6 x 20mm he

xagon head screw

and one M6 nyloc nut per side Fix each track brace to

joist using one no.12 x 1

1

/2” self tapping screw.

Lock each track hanger in position by fixing to joist

using a second no.12 x 1

1

/2” self tapping screw.

Smooth lower side seals into position, align holes in

lo

wer spring anchor brackets with holes in lower side

seals (Fig.

D). Secure each bracket using three 6mm x

50mm gold self tapping scre

w. There is no need to pilot

dr

ill for these screws.

A

C

F

With the door closed, remo

ve the park pin to

release the latch pin (Figure H) Align the catch

bracket centrally over the latch pin with the

lower face 3mm (1/8”) above the top

door bracket.

Insert 2 off No 12 x 1 1/2” self tapping screws

through screws slots into head timber, use

adjustment on screw slots to ensure correct

alignment

Open the door half way and fit lock following the

instructions in the lock pack supplied with your

door.

LHS

IMPORTANT NOTE

Prior to Fitting the Door

F

or ease of transportation and storage

some doors are supplied without the

upper weather strips attached to the

door panel. These are supplied

separately within the door fixing pack.

If y

our door is of this type then fit the

weather strips as shown below using

4 off No. 12 x

3

/4” self tapping screws

per side

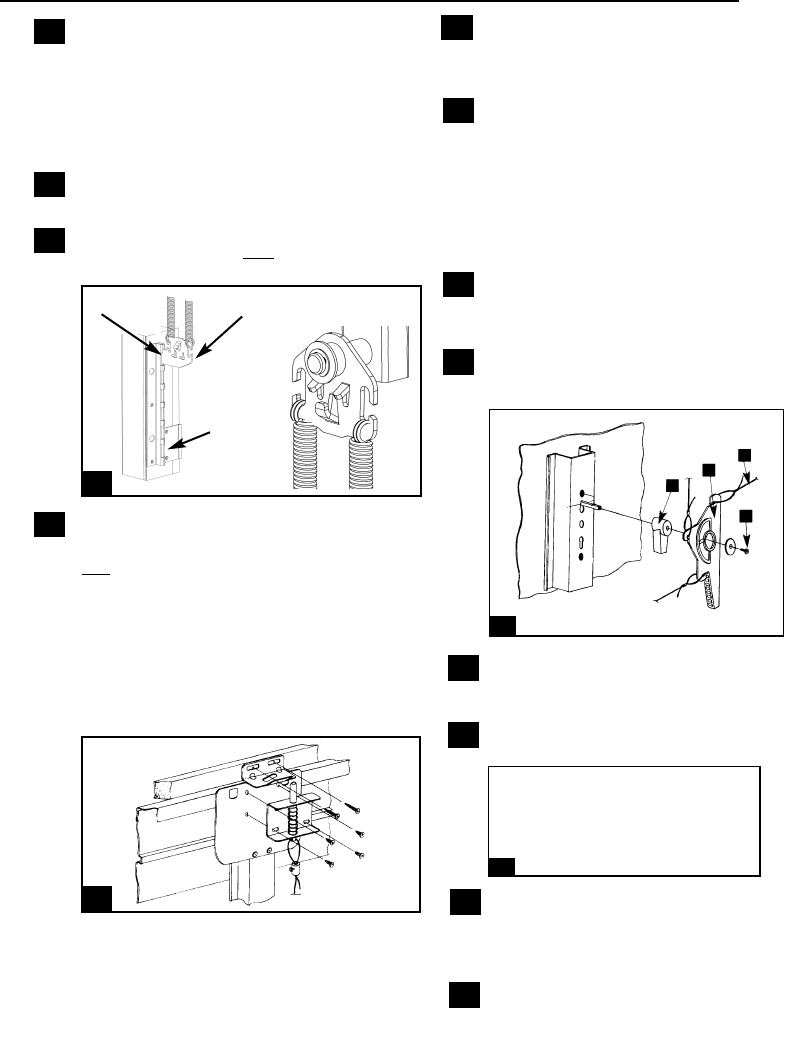

Stand door, safely propped, centrally

between side jambs on two wedges. A

gap of approximately 12mm (1/2”)

should be left between the top of the

door and the lintel

Fit pivot arms to plates in bottom

cor

ners of door using f

our no. 12 x

3

/4”

self tapping screws per side Using

outer holes shown. (See Figure A)

B

Maximizer Gear

D

Latch

Plate

7

8

9

10

E

LHS

Establish gear setting positions for door from label

attached to back of door.

Note setting 1 is top anchor

position

Still with the door in the open position and wearing eye

protection fit lower spring anchors as shown and fit

springs to spring anchors in orientation shown (See fig G).

Note Spring loops to be located on anchor bracket

hooks facing outwards so that spring body is located

in board of spring anchor brackets. When using

centre hook spring will require twisting 180 degrees.

Always use the same number of springs on each side. For

2 springs use outer hooks, for 1 spring use centre hook,

for 3 springs use all hooks. A minimum of 2 through to

maximum of 3 springs per side may be supplied

depending upon door weight.

Check door operation and re-tension if necessary. (See

maintenance label on side seals for details).

NO

TE – Some doors are supplied without the pro

vision

for a top latch to be fitted. In these instances the com-

ponents outlined in instr

uctions 15 & 16 will be surplus

to requirements. If your door is of this type proceed to

instruction 17.

13

14

15

17

H

G

18

19

20

21

22

From front of door ensure that lock handle is

turned fully anti-clockwise From inside slide

lock cam onto spindle in orientation shown

Fit lock lever onto lock cam as shown and

secure to lock spindle using self tapping

screw and washer. (See Figure I)

Locate looped ends of all latch cables securely

in lever slots and adjust for correct operation

ENGAGEMENT NOTE On adjustment of top

latch, please ensure a nominal 6mm (1/4”) pin

engagement through catch br

ac

k

et (Figure J).

Adjustment of other latches should also be set

to 6 mm latch overlap.

Chec

k oper

ation from inside garage to avoid

being locked out

I

J

Typical Lock Assembly Shown.

18

19

19

20

9

15, 16, 21

11

10

8

5

6

19

2

7

3 & 4

Single Gear

Position 1

Position 6

Fit the top latch assemb

ly into the pre-drilled

holes on the top centre door bracket using 4 off

No

. 10 x 1/2” self-tapping screws supplied

(Figure H).

Note: lower spring anchor is not handed.

(i.e. same bracket used on left and right)

Align holes in latch plates with holes in lo

wer side

seals. Drill pilot holes and secure each plate using two

no.12 x 1

1

/2” self tapping screws. Cut away flexible

lower side seals locally where latch strikes the latch

plate

Fit each wheel bracket to top corner plate of door

using four no.12 x 3/4" self tapping screws ensuring

two vertical slots in wheel bracket are facing down-

wards as shown (Figure E). Slide tracks over wheels

and press firmly up and out in the direction of arrow

until tracks are horizontal. Drill pilot holes in side jambs

and secure each track fixing bracket using two no 12 x

1

1

/2” self tapping screws and two M8 washers, ensur-

ing wheel is in contact with the bottom of the track.

Slide track hangers over ends in orientation

shown in main assembly diagram Slide to a

convenient roof joist

within 200 mm (8”) from end of

track and fix each hanger to joist using ONE no.12 x

1

1

/2” self tapping screw only at this stage. For best

results ensure tracks are hanging horizontally, square

to the frame and parallel to each other At this stage the

tracks should be able to swing sideways.

Slide track end bungs into position in orientation

shown (see Fig. F). Secure each end bung to track

using two off M6 x 30mm hexagon head bolts and two

M6 nyloc nuts ensuring nuts locate firmly into

hexagonal recess in end bung

1 FITTING YOUR DOOR

CAUTION ! Please ensure all tools and parts are inside the garage before the door is

placed in the opening.

Assembly diagram (maximizer door gear illustrated)

Numbers refer to installation notes

Swing the pivot arms up, align two holes in

each lo

wer side seal with those in main pivot

br

ackets. Ensure lip on lower side seal locates

against side of jamb f

or full length of side seal.

NO

TE: for special sized doors the bottom of

side seal must be cut short to suit installation.

Drill pilot holes and secure each main pivot

bracket using two M8 x 50mm coach screws

and two M8 washers per side. (See Fig B)

Smooth lower side seals into position. Align

pivot blocks with holes in lower side seals as

shown. (Fig. C) drill pilot holes and secure

using two no.12 x 1

1

/2”: self tapping screws

per block.

1

2

3

4

5

6 11

16

12

Fully open door and prop securely in position.

With the door still open the tr

acks should be parallel

This can be chec

ked by ensuring both roller wheels are

in contact with the tr

ack end bungs. Bolt track braces to

hangers using one M6 x 20mm he

xagon head screw

and one M6 nyloc nut per side Fix each track brace to

joist using one no.12 x 1

1

/2” self tapping screw.

Lock each track hanger in position by fixing to joist

using a second no.12 x 1

1

/2” self tapping screw.

Smooth lower side seals into position, align holes in

lo

wer spring anchor brackets with holes in lower side

seals (Fig.

D). Secure each bracket using three 6mm x

50mm gold self tapping scre

w. There is no need to pilot

dr

ill for these screws.

A

C

F

With the door closed, remo

ve the park pin to

release the latch pin (Figure H) Align the catch

bracket centrally over the latch pin with the

lower face 3mm (1/8”) above the top

door bracket.

Insert 2 off No 12 x 1 1/2” self tapping screws

through screws slots into head timber, use

adjustment on screw slots to ensure correct

alignment

Open the door half way and fit lock following the

instructions in the lock pack supplied with your

door.

LHS

IMPORTANT NOTE

Prior to Fitting the Door

F

or ease of transportation and storage

some doors are supplied without the

upper weather strips attached to the

door panel. These are supplied

separately within the door fixing pack.

If y

our door is of this type then fit the

weather strips as shown below using

4 off No. 12 x

3

/4” self tapping screws

per side

Stand door, safely propped, centrally

between side jambs on two wedges. A

gap of approximately 12mm (1/2”)

should be left between the top of the

door and the lintel

Fit pivot arms to plates in bottom

cor

ners of door using f

our no. 12 x

3

/4”

self tapping screws per side Using

outer holes shown. (See Figure A)

B

Maximizer Gear

D

Latch

Plate

7

8

9

10

E

LHS

Establish gear setting positions for door from label

attached to back of door.

Note setting 1 is top anchor

position

Still with the door in the open position and wearing eye

protection fit lower spring anchors as shown and fit

springs to spring anchors in orientation shown (See fig G).

Note Spring loops to be located on anchor bracket

hooks facing outwards so that spring body is located

in board of spring anchor brackets. When using

centre hook spring will require twisting 180 degrees.

Always use the same number of springs on each side. For

2 springs use outer hooks, for 1 spring use centre hook,

for 3 springs use all hooks. A minimum of 2 through to

maximum of 3 springs per side may be supplied

depending upon door weight.

Check door operation and re-tension if necessary. (See

maintenance label on side seals for details).

NO

TE – Some doors are supplied without the pro

vision

for a top latch to be fitted. In these instances the com-

ponents outlined in instr

uctions 15 & 16 will be surplus

to requirements. If your door is of this type proceed to

instruction 17.

13

14

15

17

H

G

18

19

20

21

22

From front of door ensure that lock handle is

turned fully anti-clockwise From inside slide

lock cam onto spindle in orientation shown

Fit lock lever onto lock cam as shown and

secure to lock spindle using self tapping

screw and washer. (See Figure I)

Locate looped ends of all latch cables securely

in lever slots and adjust for correct operation

ENGAGEMENT NOTE On adjustment of top

latch, please ensure a nominal 6mm (1/4”) pin

engagement through catch br

ac

k

et (Figure J).

Adjustment of other latches should also be set

to 6 mm latch overlap.

Chec

k oper

ation from inside garage to avoid

being locked out

I

J

Typical Lock Assembly Shown.

18

19

19

20

9

15, 16, 21

11

10

8

5

6

19

2

7

3 & 4

Single Gear

Position 1

Position 6

Fit the top latch assemb

ly into the pre-drilled

holes on the top centre door bracket using 4 off

No

. 10 x 1/2” self-tapping screws supplied

(Figure H).

Note: lower spring anchor is not handed.

(i.e. same bracket used on left and right)

Align holes in latch plates with holes in lo

wer side

seals. Drill pilot holes and secure each plate using two

no.12 x 1

1

/2” self tapping screws. Cut away flexible

lower side seals locally where latch strikes the latch

plate

Fit each wheel bracket to top corner plate of door

using four no.12 x 3/4" self tapping screws ensuring

two vertical slots in wheel bracket are facing down-

wards as shown (Figure E). Slide tracks over wheels

and press firmly up and out in the direction of arrow

until tracks are horizontal. Drill pilot holes in side jambs

and secure each track fixing bracket using two no 12 x

1

1

/2” self tapping screws and two M8 washers, ensur-

ing wheel is in contact with the bottom of the track.

Slide track hangers over ends in orientation

shown in main assembly diagram Slide to a

convenient roof joist

within 200 mm (8”) from end of

track and fix each hanger to joist using ONE no.12 x

1

1

/2” self tapping screw only at this stage. For best

results ensure tracks are hanging horizontally, square

to the frame and parallel to each other At this stage the

tracks should be able to swing sideways.

Slide track end bungs into position in orientation

shown (see Fig. F). Secure each end bung to track

using two off M6 x 30mm hexagon head bolts and two

M6 nyloc nuts ensuring nuts locate firmly into

hexagonal recess in end bung

1 FITTING YOUR DOOR

CAUTION ! Please ensure all tools and parts are inside the garage before the door is

placed in the opening.

Assembly diagram (maximizer door gear illustrated)

Numbers refer to installation notes

Swing the pivot arms up, align two holes in

each lo

wer side seal with those in main pivot

br

ackets. Ensure lip on lower side seal locates

against side of jamb f

or full length of side seal.

NO

TE: for special sized doors the bottom of

side seal must be cut short to suit installation.

Drill pilot holes and secure each main pivot

bracket using two M8 x 50mm coach screws

and two M8 washers per side. (See Fig B)

Smooth lower side seals into position. Align

pivot blocks with holes in lower side seals as

shown. (Fig. C) drill pilot holes and secure

using two no.12 x 1

1

/2”: self tapping screws

per block.

1

2

3

4

5

6 11

16

12

Fully open door and prop securely in position.

With the door still open the tr

acks should be parallel

This can be chec

ked by ensuring both roller wheels are

in contact with the tr

ack end bungs. Bolt track braces to

hangers using one M6 x 20mm he

xagon head screw

and one M6 nyloc nut per side Fix each track brace to

joist using one no.12 x 1

1

/2” self tapping screw.

Lock each track hanger in position by fixing to joist

using a second no.12 x 1

1

/2” self tapping screw.

Smooth lower side seals into position, align holes in

lo

wer spring anchor brackets with holes in lower side

seals (Fig.

D). Secure each bracket using three 6mm x

50mm gold self tapping scre

w. There is no need to pilot

dr

ill for these screws.

A

C

F

With the door closed, remo

ve the park pin to

release the latch pin (Figure H) Align the catch

bracket centrally over the latch pin with the

lower face 3mm (1/8”) above the top

door bracket.

Insert 2 off No 12 x 1 1/2” self tapping screws

through screws slots into head timber, use

adjustment on screw slots to ensure correct

alignment

Open the door half way and fit lock following the

instructions in the lock pack supplied with your

door.

LHS

IMPORTANT NOTE

Prior to Fitting the Door

F

or ease of transportation and storage

some doors are supplied without the

upper weather strips attached to the

door panel. These are supplied

separately within the door fixing pack.

If y

our door is of this type then fit the

weather strips as shown below using

4 off No. 12 x

3

/4” self tapping screws

per side

Stand door, safely propped, centrally

between side jambs on two wedges. A

gap of approximately 12mm (1/2”)

should be left between the top of the

door and the lintel

Fit pivot arms to plates in bottom

cor

ners of door using f

our no. 12 x

3

/4”

self tapping screws per side Using

outer holes shown. (See Figure A)

B

Maximizer Gear

D

Latch

Plate

7

8

9

10

E

LHS

Establish gear setting positions for door from label

attached to back of door.

Note setting 1 is top anchor

position

Still with the door in the open position and wearing eye

protection fit lower spring anchors as shown and fit

springs to spring anchors in orientation shown (See fig G).

Note Spring loops to be located on anchor bracket

hooks facing outwards so that spring body is located

in board of spring anchor brackets. When using

centre hook spring will require twisting 180 degrees.

Always use the same number of springs on each side. For

2 springs use outer hooks, for 1 spring use centre hook,

for 3 springs use all hooks. A minimum of 2 through to

maximum of 3 springs per side may be supplied

depending upon door weight.

Check door operation and re-tension if necessary. (See

maintenance label on side seals for details).

NO

TE – Some doors are supplied without the pro

vision

for a top latch to be fitted. In these instances the com-

ponents outlined in instr

uctions 15 & 16 will be surplus

to requirements. If your door is of this type proceed to

instruction 17.

13

14

15

17

H

G

18

19

20

21

22

From front of door ensure that lock handle is

turned fully anti-clockwise From inside slide

lock cam onto spindle in orientation shown

Fit lock lever onto lock cam as shown and

secure to lock spindle using self tapping

screw and washer. (See Figure I)

Locate looped ends of all latch cables securely

in lever slots and adjust for correct operation

ENGAGEMENT NOTE On adjustment of top

latch, please ensure a nominal 6mm (1/4”) pin

engagement through catch br

ac

k

et (Figure J).

Adjustment of other latches should also be set

to 6 mm latch overlap.

Chec

k oper

ation from inside garage to avoid

being locked out

I

J

Typical Lock Assembly Shown.

18

19

19

20

9

15, 16, 21

11

10

8

5

6

19

2

7

3 & 4

Single Gear

Position 1

Position 6

Fit the top latch assemb

ly into the pre-drilled

holes on the top centre door bracket using 4 off

No

. 10 x 1/2” self-tapping screws supplied

(Figure H).

Note: lower spring anchor is not handed.

(i.e. same bracket used on left and right)

CAUTION

This gar

age door has been designed to be as as easy as possible to use, service and automate when installed

correctly. Please therefore take time to read these instructions fully before beginning any work. Note: This door has

been designed to hang on a 70mm x 70mm timber goalpost fr

ame (not supplied).

IMPORTANT INFORMATION

1 This garage door is intended for domestic use only.

2 Garage doors are heavy and may have sharp edges.

Wear protective gloves. Installation should not be undertaken

alone.Care must be taken when handling.

3 Ensure the door is continuously supported before it is secured

and avoid installing in windy conditions.

4 Do not attempt to install or adjust this door if you are unsure of

any of the instructions below.

BEFORE COMMENCING WORK

Remove all wrapping

Before starting: remove all wrapping and check door has been supplied with correct

lifting gear kit. Kit code is on identification label on reverse of door.

Check opening size

Before fitting door, check opening size and squareness of timber frame. The door is made

smaller to give correct clearance within the frame.

Check headroom

There must be a minimum of 42mm headroom above lower face of top timber or lintel.

This must reach back into the garage for at least 1875mm.

Check the “goalpost” frame

The “goalpost” timber frame should be a minimum of 70mm x 70mm square (2

3

/

4

” x 2

3

/

4

”),

in good condition and securely fixed to the surrounding structure.

Tools

All the initial fitting work is done from inside the garage, so all tools and parts should be to

hand there before door is placed in opening.

1

2

3

4

5

You will need:

• 6mm & 10 mm flat bladed screwdriver • Tape measure

• No 2 & 3 posi-drive screwdriver • hammer

• Drill and 2.5mm drill bit (for pilot holes) • Grease

• 13mm A/F socket/spanner • Engineer’s pliers

• 10mm A/F socket/spanner • 19mm x 19mm timber weatherbead to fit under

• 7mm A/F socket/spanner the head of the door frame

• Protective gloves • 70mm x 70mm timber goal post frame

•

Shar

p knif

e

•

W

edges (pac

king pieces)

Note to installer: Please ensure that this instruction sheet remains with the door for the owner’s future reference.

ISSUE B MAY 2005 DPIN 045112

•

DOOR IS HEAVY TO OPEN:

Cause: Spring tension set too low

Solution: Re-set spring tension as detailed on the door maintenance label.

•

DOOR OPENS TOO QUICKLY:

Causes: Spring tension set too high.

Solution: Re-set spring tension as detailed on the door maintenance label.

•

DOOR DOES NOT DELATCH:

Cause: Latch cables may have been set too long.

Solution: If you are not locked out of the garage at the time, then the cables should be set to allow nominal

6mm latch engagement with the latch plates. If you are locked out of the garage, call your installer/supplier

for assistance.

•

DOOR HANDLE FAILS TO TURN:

Probable Cause: A jammed lock barrel.

Solution: Unfortunately this can only be remedied by a service call, however, this is not usually chargeable

during the warranty period. Please contact your supplier for details.

•

KEY FAILS TO TURN IN LOCK:

Probable Cause: Door handle has not been turned to the fully closed position.

Solution: Return the handle to the fully closed (horizontal) position and try again. If the problem still persists,

contact your supplier.

•

LOST KEYS:

Solution:

Contact your supplier. The lock barrel will need to be replaced, but the method for doing this will

vary. If you can get into your garage, the problem can be easily solved by removing the handle assembly

from the door and replacing the lock barrel with a new one. If you are locked out, contact your supplier.

THESE INSTRUCTIONS MUST BE FOLLOWED CAREFULLY

GARAGE DOORS ARE HEAVY AND AWKWARD TO HANDLE. ENSURE

ASSISTANCE IS AVAILABLE AND THAT SAFETY GLOVES ARE WORN.

1. Fix all latches in the fully retracted position.

2. Open door and safely prop in the open position.

3. Remove springs from their hangers. (wear eye protection).

4. With assistance remove prop and close door slowly until fully closed.

5. Prop door in fully closed position and place packers beneath the door between

base of door and floor.

6. Remove all track supports and remove track fixing screws from the frame and

remove.

7. Remove fixings to main pivot brackets, door should now rest on packers.

8. Remove bottom door mounting brackets.

9. Remove main pivot blocks.

10. The door can now be carefully removed from the opening. Seek assistance

in lifting.

11. If door is to be disposed of please do so in a responsible manner in line with the

latest legislation applicable at the time.

Slideaway

Double & Heavy Double Door Gear

INSTALLATION INSTRUCTIONS

11

Slideaway

Single & Maximizer Door Gear

TROUBLE SHOOTING

POWER OPERATION

UPON COMPLETION

2

Fix lower side seals into position using five 1” clout nails

per side.

Check door operation to ensure door opens and closes

satisfactorily.

Check that lock and latches operate correctly.

Ensure all fixings are securely tightened

Fit 19mm

× 19mm timber weatherbead to the underside of

the top timber lintel (Fig K).

Do not paint the spring or any moving parts.

Lubricate all moving parts/pivot points (refer to

maintenance label for details) lubrication is an essential

ongoing requirement to ensure the continuing smooth

operation of your door.

Ask your professional Garage Door Specialist about

remote controlled electric operators.

Lintel

Door

19mm

× 19mm

Weatherbead

1

2

3

4

5

6

7

8

K

DISMANTLING INSTRUCTIONS

In the event of difficulty please contact your local Garage Door Specialist or call our

Gara

g

e Door Helpline.

See main CE label for details

This door is suitable for power operation. In order to conform with current legislation

only independantly tested and certified operators may be fitted. A list of approved

operators is contained on the Declaration of Incorporation supplied with your door.

CAUTION

This gar

age door has been designed to be as as easy as possible to use, service and automate when installed

correctly. Please therefore take time to read these instructions fully before beginning any work. Note: This door has

been designed to hang on a 70mm x 70mm timber goalpost fr

ame (not supplied).

IMPORTANT INFORMATION

1 This garage door is intended for domestic use only.

2 Garage doors are heavy and may have sharp edges.

Wear protective gloves. Installation should not be undertaken

alone.Care must be taken when handling.

3 Ensure the door is continuously supported before it is secured

and avoid installing in windy conditions.

4 Do not attempt to install or adjust this door if you are unsure of

any of the instructions below.

BEFORE COMMENCING WORK

Remove all wrapping

Before starting: remove all wrapping and check door has been supplied with correct

lifting gear kit. Kit code is on identification label on reverse of door.

Check opening size

Before fitting door, check opening size and squareness of timber frame. The door is made

smaller to give correct clearance within the frame.

Check headroom

There must be a minimum of 42mm headroom above lower face of top timber or lintel.

This must reach back into the garage for at least 1875mm.

Check the “goalpost” frame

The “goalpost” timber frame should be a minimum of 70mm x 70mm square (2

3

/

4

” x 2

3

/

4

”),

in good condition and securely fixed to the surrounding structure.

Tools

All the initial fitting work is done from inside the garage, so all tools and parts should be to

hand there before door is placed in opening.

1

2

3

4

5

You will need:

• 6mm & 10 mm flat bladed screwdriver • Tape measure

• No 2 & 3 posi-drive screwdriver • hammer

• Drill and 2.5mm drill bit (for pilot holes) • Grease

• 13mm A/F socket/spanner • Engineer’s pliers

• 10mm A/F socket/spanner • 19mm x 19mm timber weatherbead to fit under

• 7mm A/F socket/spanner the head of the door frame

• Protective gloves • 70mm x 70mm timber goal post frame

•

Shar

p knif

e

•

W

edges (pac

king pieces)

Note to installer: Please ensure that this instruction sheet remains with the door for the owner’s future reference.

ISSUE B MAY 2005 DPIN 045112

•

DOOR IS HEAVY TO OPEN:

Cause: Spring tension set too low

Solution: Re-set spring tension as detailed on the door maintenance label.

•

DOOR OPENS TOO QUICKLY:

Causes: Spring tension set too high.

Solution: Re-set spring tension as detailed on the door maintenance label.

•

DOOR DOES NOT DELATCH:

Cause: Latch cables may have been set too long.

Solution: If you are not locked out of the garage at the time, then the cables should be set to allow nominal

6mm latch engagement with the latch plates. If you are locked out of the garage, call your installer/supplier

for assistance.

•

DOOR HANDLE FAILS TO TURN:

Probable Cause: A jammed lock barrel.

Solution: Unfortunately this can only be remedied by a service call, however, this is not usually chargeable

during the warranty period. Please contact your supplier for details.

•

KEY FAILS TO TURN IN LOCK:

Probable Cause: Door handle has not been turned to the fully closed position.

Solution: Return the handle to the fully closed (horizontal) position and try again. If the problem still persists,

contact your supplier.

•

LOST KEYS:

Solution:

Contact your supplier. The lock barrel will need to be replaced, but the method for doing this will

vary. If you can get into your garage, the problem can be easily solved by removing the handle assembly

from the door and replacing the lock barrel with a new one. If you are locked out, contact your supplier.

THESE INSTRUCTIONS MUST BE FOLLOWED CAREFULLY

GARAGE DOORS ARE HEAVY AND AWKWARD TO HANDLE. ENSURE

ASSISTANCE IS AVAILABLE AND THAT SAFETY GLOVES ARE WORN.

1. Fix all latches in the fully retracted position.

2. Open door and safely prop in the open position.

3. Remove springs from their hangers. (wear eye protection).

4. With assistance remove prop and close door slowly until fully closed.

5. Prop door in fully closed position and place packers beneath the door between

base of door and floor.

6. Remove all track supports and remove track fixing screws from the frame and

remove.

7. Remove fixings to main pivot brackets, door should now rest on packers.

8. Remove bottom door mounting brackets.

9. Remove main pivot blocks.

10. The door can now be carefully removed from the opening. Seek assistance

in lifting.

11. If door is to be disposed of please do so in a responsible manner in line with the

latest legislation applicable at the time.

Slideaway

Double & Heavy Double Door Gear

INSTALLATION INSTRUCTIONS

11

Slideaway

Single & Maximizer Door Gear

TROUBLE SHOOTING

POWER OPERATION

UPON COMPLETION

2

Fix lower side seals into position using five 1” clout nails

per side.

Check door operation to ensure door opens and closes

satisfactorily.

Check that lock and latches operate correctly.

Ensure all fixings are securely tightened

Fit 19mm

× 19mm timber weatherbead to the underside of

the top timber lintel (Fig K).

Do not paint the spring or any moving parts.

Lubricate all moving parts/pivot points (refer to

maintenance label for details) lubrication is an essential

ongoing requirement to ensure the continuing smooth

operation of your door.

Ask your professional Garage Door Specialist about

remote controlled electric operators.

Lintel

Door

19mm

× 19mm

Weatherbead

1

2

3

4

5

6

7

8

K

DISMANTLING INSTRUCTIONS

In the event of difficulty please contact your local Garage Door Specialist or call our

Gara

g

e Door Helpline.

See main CE label for details

This door is suitable for power operation. In order to conform with current legislation

only independantly tested and certified operators may be fitted. A list of approved

operators is contained on the Declaration of Incorporation supplied with your door.